A pink hue from multi coloured LED lights hang over a bed of aeroponically cultivated hemp plants that are part of the first stage of the Rocky Mountain Marijuana Inc. (RMMI)

(C.RMMI, Forum) cannabis facility in the County of Newell.

The full-spectrum arrays of LED lamps provide tables of plants optimal light for energy.

“We can program the LED’s intensity as well as the time they are on,” said Dr. Surinder Singh, chief scientist at RMMI.

Singh, who can control and monitor the plants’ environment from anywhere in the world, looks at the light, water and nutrients needed for successful growth and air temperature.

“We can monitor all of the plant tables all of the time,” he said.

Using hemp, the genetic cousin to cannabis, RMMI is testing all aspects of plant growth from seedlings to harvest as the company prepares to operate under the Cannabis Act to cultivate marijuana and extract cannabis oils.

“Cannabis oils can be used to create other derivative products including edibles, drinkables and topicals,” stated Eugene Chen, a director at RMMI, in a news release.

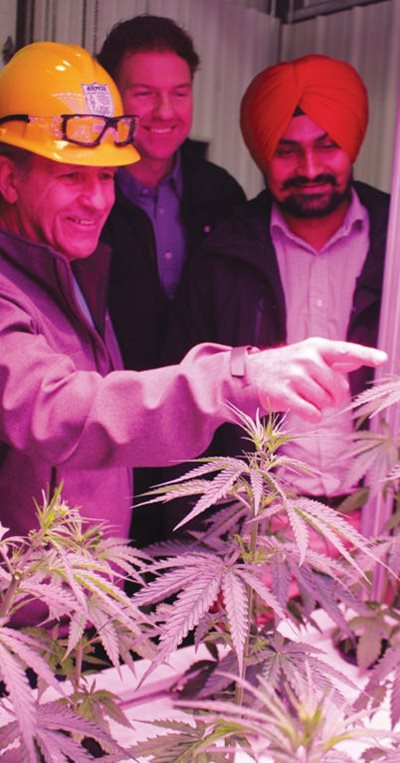

Earl Connors, George Jurcic and Dr. Surinder Singh of Rocky Mountain Marijuana Inc. (RMMI) look at some of the hemp plants that were aeroponically grown. | SANDRA M STANWAY PHOTO

Earl Connors, George Jurcic and Dr. Surinder Singh of Rocky Mountain Marijuana Inc. (RMMI) look at some of the hemp plants that were aeroponically grown. | SANDRA M STANWAY PHOTO

In July 2018 county council gave the company the go ahead to build the plant in the Martin Subdivision.

That same year RMMI received its hemp licence as part of its plan to perfect cannabis growth making changes and adjustments along the way.

“We weigh them, measure their height and breadth and perform various studies of them,” said Earl Connors, president and CEO of RMMI.

Studies include determining the optimal flowering period drying times and other parameters that are important to maximum oil extraction.

“We must dry marijuana for a period before we can process dry products or extract oil from the plants,” said Singh.

The aeroponic cultivation systems was chosen because they produce higher yields, facilitate shorter growing cycles, reduce risk of contamination, are more environmentally friendly and use a smaller footprint than soil-growing methods.

Across the country various manufacturers’ products have been recalled for contamination, faulty products and labelling issues. In January one product was called due to mould.

Because aeroponics does not use soil or pots which can result in contamination, the company is eliminating the risk in order to provide a product the team hopes will be a go-to business.

“We intend to produce the highest quality, highest product possible with aeroponics,” said Connors.

While the company is only operating in a temporary facility, Connors is obviously thrilled with the results of the plants.

Dr. Surinder Singh holds a hemp plant that is in the early stages of aeroponic growth.

Dr. Surinder Singh holds a hemp plant that is in the early stages of aeroponic growth.

| SANDRA M STANWAY PHOTO |

“Look at the results we’re getting with a less than optimal, temporary facility. Imagine when we have our facility built out in the main building. It’s going to be incredible,” he said.

Once the 23,400 sq. foot building is fully populated with aeroponics systems, it is expected to produce 8,200 kg of dry product or 1,800 litres of oil annually.

“We will get at least five crops a year; six is easily attainable,” said Connors.

When the plants are harvested, they will be moved to the company’s processing area where the stalks will become biowaste for composting and oil will be extracted from the leaves and flowers.

Prior to licensing for the sale of dry products and oils, Health Canada will inspect the facility, equipment and records and following two successful marijuana cultivations the company expects to receive their sales licence.

“If you don’t have the results to show them you don’t get the licence,” said Connors.

Not only is Connors proud of the plants but also the community as a whole.

“It’s a true Alberta story,” he said.

The construction, mechanical and electrical contractors are local, the interior and exterior building panels which must be impenetrable to keep pests out, are manufactured in Innisfail and the engineers are from Calgary.

“It just thrills me that we were able to do all of this in southern Alberta. It’s been a terrific experience,” Connors said.

He said the company selected the county because of the location, the welcoming reception they received from county staff and their high level of cooperation.

“When we start production hopefully, we will draw again from the local community,” he said.

FULL DISCLOSURE: This is a paid article produced by Stockhouse Publishing.