As automotive manufacturers view their options for reducing fuel consumption and emissions, electrical propulsion becomes more attractive. Historically, internal permanent magnet (IPM) motors have been a popular motor design. They provide high torque density and high peak efficiency, but there are some disadvantages. Stator losses can be significant; they require expensive controllers and rely on rare earth magnet materials. A potential alternative to the IPM is the induction motor. Induction motors have been used successfully in production vehicles. They have comparable torque density and peak efficiency and a rugged, durable design. Induction motors do not suffer a drag loss when the motor turns and do not lose efficiency during high speed, low torque conditions, making them well suited for hybrid and plug-in hybrid applications.

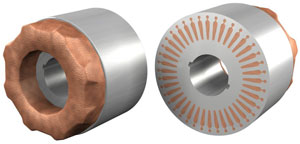

Illustrated cutaway showing end rings and rotor bars inside the rotor stack

Replacing an aluminum rotor with a copper rotor will increase the advantages of an induction motor. The copper rotor bars and end rings reduce electrical losses, leading to a smaller, more efficient motor. Automotive engineers had experimented with fabricated copper rotors but were constantly looking for an efficient, high production process, such as die casting.

Die casting copper is more challenging than die casting aluminum because of copper's much higher melting temperature. The International Copper Association, Ltd. (ICA) and the Copper Development Association Inc. (CDA) realized the need to improve casting technology and conducted extensive research on casting copper rotors for industrial applications. They quickly saw need to share this information with automotive engineers and are actively promoting cast copper rotors to the transportation industry.

Finished samples of cast copper rotors produced at one of the copper technical centers

In addition to the increased efficiencies, copper rotors can provide an economic advantage over aluminum rotors. Although the raw material cost for aluminum may be less than copper, the motor with a cast copper rotor can be 15 - 25% smaller than an equivalent motor with an aluminum rotor. This results in considerable savings by reducing the amount of electrical grade lamination steel and the number of stampings. The superior heat conduction properties of copper also make thermal management easier, which can be another source of cost reduction for the complete system.

With these advantages, it is not surprising that a number of manufacturers are evaluating induction motors with cast copper rotors for future vehicles. Because the ICA and the CDA recognize the global nature of the automobile industry, they have developed a network of partners and centers of technical expertise to aid engineers and designers, including facilities in North America, Asia and Europe. Copper has always been recognized as the preferred material for conducting electricity, which is why it is used universally in motor windings. Now the copper industry is providing assistance to engineers and designers to bring improved technology to the motor rotor for hybrid and electric vehicles.