Tesla Silicon Neo Battery compares its silicon anodes to graphite anodes but what about others doing silicon anodes?

Tesla

No conversation about EV battery innovation is complete without the mention of Tesla, and as per usual, the company is well ahead of its competitors when it comes to R&D. Silicon has already been used in Tesla vehicles for a few years.

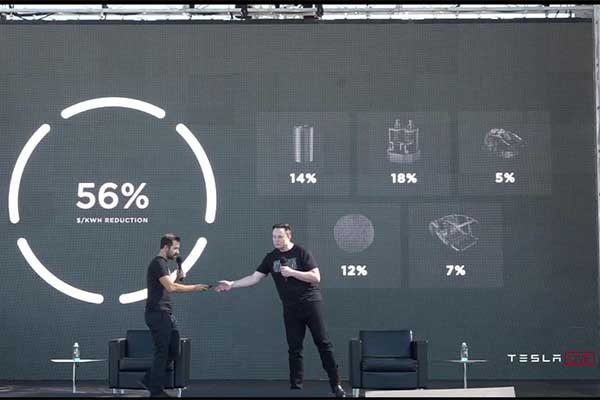

IMAGE: Screen capture from Tesla’s “Battery Day” presentation. The five pillars of Tesla’s strategy to reduce vehicle and battery cost

IMAGE: Screen capture from Tesla’s “Battery Day” presentation. The five pillars of Tesla’s strategy to reduce vehicle and battery cost However, these solutions, such as silicon nanowires, are highly engineered and expensive. As a result, they can’t be scaled. Tesla’s new silicon anode method, dubbed “Tesla Silicon,” costs just $1.20/kWh — roughly 6-10x cheaper than current or other methods used to date. Tesla Silicon begins with raw metallurgical silicon, no engineering required.

The battery is designed to account for the expansion of silicon, rather than constrain it. Tesla describes their silicon as featuring an “elastic binder and electrode design” in addition to an “elastic, ion-conducting, polymer coating.”

These changes alone are projected to increase Tesla’s battery range by 20% and decrease costs by 5% per kWh. One of the most significant benefits of using raw metallurgical silicon is that manufacturing costs can be significantly reduced by forgoing early engineering processes. This also means the solution is easy to scale, as it doesn’t require any high upfront capital expenditures.