First Generation of Advance Silicon-Based Anode Material Continues Delivering Strong Performance

- 18650 batteries testing continues to deliver 14% performance improvement versus graphite benchmark batteries with minimal battery degradation rates at 125 cycles [1].

MONTREAL, April 18, 2024 (GLOBE NEWSWIRE) -- HPQ Silicon Inc. (“HPQ” or the “Company”) (TSX-V: HPQ) (OTCQB: HPQFF) (FRA: O08), a technology company specializing in green engineering of silica and silicon-based materials is pleased to announce continued milestones achieved by its France-based affiliate, NOVACIUM SAS ("Novacium"). This announcement highlights the promising results from ongoing cycle testing of 'industry standard' 18650 industrial batteries, notably at the 125-cycle mark. Additionally, it introduces the massive market opportunity for HPQ associated with advanced silicon-based anodes material manufacturing.

“The fact that our first generation of advanced silicon-based material continues to deliver about 3,100 milliampere-hour (mAh) of battery capacity after 125 cycles [1] is a powerful indication of the commercial potential of the materials we are developing for Advanced Mobile Technology applications, a US$ 228.9B addressable market in 2023 [2],” stated Dr. Jed Kraiem Ph.D., COO of Novacium. “These results underscore our ability to produce a blend of graphite and advanced engineered silicon anode material that can be seamlessly integrated into existing anode manufacturing facilities and utilized without requiring modification by battery manufacturers worldwide, all the while significantly enhancing the battery performances.”

CONTINUING TO DELIVER 14% BATTERY CAPACITY IMPROVEMENT AT 125 CYCLES

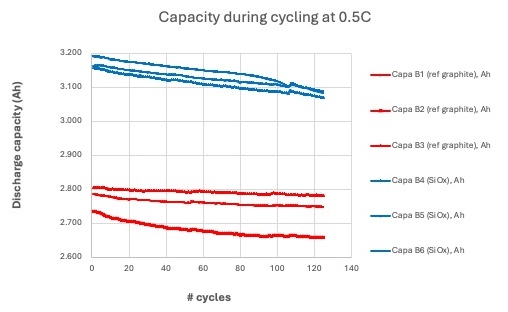

The data from Figure 1 below demonstrate that the three industrial-type batteries, which utilize Novacium's first generation of custom-engineered silicon material blend, (blue lines), continue to achieve > 14% performance improvement over 125 cycles. These batteries exhibit a high discharge capacity of approximately 3.10 Ampere-hours (Ah) (or about 3,100 mAh), surpassing the benchmark set by three comparison batteries (red lines) which have a capacity of about 2.65 Ah. These results, confirm and extend the approximate 14% enhancement in full-battery capacity compared to 100% graphite benchmark batteries, that was observed in the previous 5, 25, 50 and 100 cycles testing.

Figure 1) shows battery capacity during 125 cycles tests of

HPQ and Novacium Gen 1 18650 industrial battery [1].

CONTINUING TO DELIVER MINIMAL BATTERY DEGRADATION AT 125 CYCLES

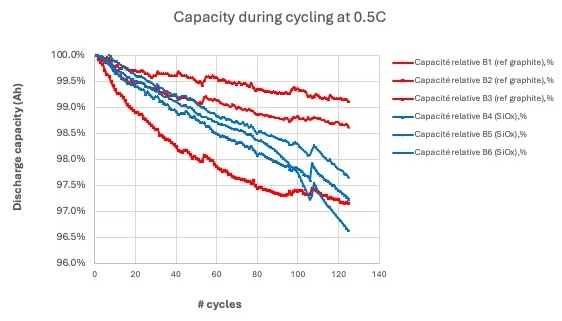

Results from Figure 2 continue to demonstrate minimal increase in the measurable cycle degradation between the batteries made entirely of graphite (the red lines) and those incorporating Novacium's custom-engineered silicon-based material blend (the blue lines), between the 100 cycles and the 125 cycles, as expected. The Novacium non-optimized first generation of engineered silicon anodes material continue to deliver results within the range of comparable graphite batteries. These promising results have real world applications.

Figure 2) shows the capacity change during 125 cycles tests

of HPQ and Novacium Gen 1 18650 industrial battery [1].

“The data generated during testing continues to provide the crucial information needed to develop an enhanced second generation of advanced silicon-based material, that we believe will allow us to deliver even better results,” added Dr. Kraiem. “This material is presently being utilized in the production of additional batches of 18650 batteries to be tested.”

ADVANCE SILICON-BASED ENGINEERED ANODES MATERIAL MARKET OPPORTUNITY

As pure graphite anodes have essentially achieved their maximum performance in terms of energy density [3], a trend in the lithium battery industry has been the introduction of small amounts (about 5%) of silicon oxide (SiOx) material into graphite composite electrodes. This basic SiOx material, primarily used in the fabrication of optical materials, sells for about US$15 per kg [4] and delivers less than optimal results.

While Silicon remains the most promising candidate that can drastically improve the anode performance (more than 10 times), its industrial application is still very limited due to unresolved issues related to volumetric expansion or due to the usage of very complex and highly expensive solutions.

The manufacture of an engineered silicon-based anode material, such as the Novacium product, will enable the battery industry to overcome these problems and increase battery capacity without significant degradation of the battery's lifetime. Presently the selling price of engineered silicon-based anode material is around US$75 to US$100 per kg [4]. The Si-C material made using CVD deposition of Silane material sells for about US$300 per kg [4], which is not feasible for massive industrial application.

This new reality is driving a surge in demand for advanced silicon-based anode materials. As of 2023, this market is valued between US$1.1 billion [5] and US$2.7 billion [6]. Its growth prospects indicate a potential demand of 300,000 tons by 2030, estimated at US$15 billion [5], according to one source, and US$ 131.6 billion in 2033 according to another source [7].

It is important to highlight that silicon-based materials for Li-ion batteries currently make up a relatively small portion, accounting for less than 10%, of the global demand for graphite, which is primarily used in the manufacture of anode materials for Li-ion batteries. This graphite market is estimated to be worth US$25 billion in 2023 [8].

“I continue to be profoundly encouraged by the results to date; however, I am even more excited about the potential of our next generations of materials,” expressed Mr. Bernard Tourillon, President and CEO of HPQ Silicon Inc. and NOVACIUM SAS. “These achievements open the door for HPQ to become one of the first North American manufacturers of advance engineered silicon-based anode materials in a jurisdiction that supports these types of initiatives as it aims to become a central hub for battery material manufacturing in North America.”

REFERENCE SOURCES

[1] Novacium technical team analysis of the data from the ongoing charging and discharging cycle tests conducted at a world-leading university, the name of which is kept confidential for competitive reasons.

[2] According to Grand View Research, the global mobile application market size was valued at US$ 228.98 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 14.3% from 2024 to 2030. (Link to source.)

[3] The Royal Society of Chemistry 2020 Sustainable Energy Fuels, 2020, 4, 5387–5416

[4] Management estimates based on confidential price quotes received for materials by HPQ affiliated company.

[5] QY Research, SNE Research, Shinhan Securities / NBM June 2023 Deck page 11

[6] The global silicon anode battery market is likely to be valued at US$ 2.7 billion in 2023.

From Future Market Insights Global and Consulting Pvt. Ltd.

[7] According to Future Market Insights, the global silicon anode battery market is Estimated to Reach US$ 131.6 Billion by 2033.

[8] Based on the analysis by Fact.MR, the global graphite market is valued to be US$ 25.9 billion in 2023 and it is expected to grow at a CAGR of 8,5% to reach US$ 58,6 billion by the end of 2033. Link to source

About NOVACIUM SAS

Novacium is an HPQ - affiliated company started in Q3 2022. This green technology startup is based in Lyon, France and is a partnership with HPQ and three of France’s leading research engineers, Dr. Jed KRAIEM PhD, Novacium's Chief Operating Officer (“COO”), Dr. Oleksiy NICHIPORUK PhD, Novacium's Chief Technical Officer (“CTO”), and Dr. Julien DEGOULANGE PhD, Novacium’s Chief Innovation Officer (“CIO”). Novacium is a new Research and Development company which allows the researchers to develop their own technology in high added value fields connected to renewable energy, and allows HPQ Silicon Inc, a Canadian company, to expand the depth and reach of its technical team to help develop its silicon and new renewable energy projects.

About HPQ Silicon

HPQ Silicon Inc. (TSX-V: HPQ) is a Quebec-based TSX Venture Exchange Tier 1 Industrial Issuer.

HPQ is developing, with the support of world-class technology partners PyroGenesis Canada Inc. and NOVACIUM SAS, new green processes crucial to make the critical materials needed to reach net zero emissions.

HPQ activities are centred around the following four (4) pillars:

| 1) | Becoming a green low-cost (Capex and Opex) manufacturer of Fumed Silica using the FUMED SILICA REACTOR, a proprietary technology owned by HPQ being developed for HPQ by PyroGenesis. |

| | |

| 2) | Becoming a producer of silicon-based anode materials for battery applications with the assistance of NOVACIUM SAS. |

| | |

| 3) | HPQ SILICON affiliate NOVACIUM SAS is developing a low carbon, chemical base on demand and high-pressure autonomous hydrogen production system. |

| | |

| 4) | Becoming a zero CO2 low-cost (Capex and Opex) producer of High Purity Silicon (2N+ to 4N) using our PUREVAP™ “Quartz Reduction Reactors” (QRR), a proprietary technology owned by HPQ being developed for HPQ by PyroGenesis. |

| | |

For more information, please visit HPQ Silicon web site.