Concentrate Powder in Transport How Does Mineral Processing Work?

Once the ore is transported to the surface of the mine, haulers feed the crushers with tonnes of large rocks, the first step in mineral processing.

After they are crushed to about 15 cm (6 in) in diameter, conveyor belts route the materials into stockpiles near the concentrator building for grinding.

A conveyor belt transports the crushed rock into the concentrator building to be further diminished by SAG grinding mills. There, the ore is either mixed in with water or kept dry and then undergoes the grinding process. Materials are ground to about 5 cm (2 in) in diameter.

SAG grinding mill with a stockpile in the background

SAG grinding mill with a stockpile in the background

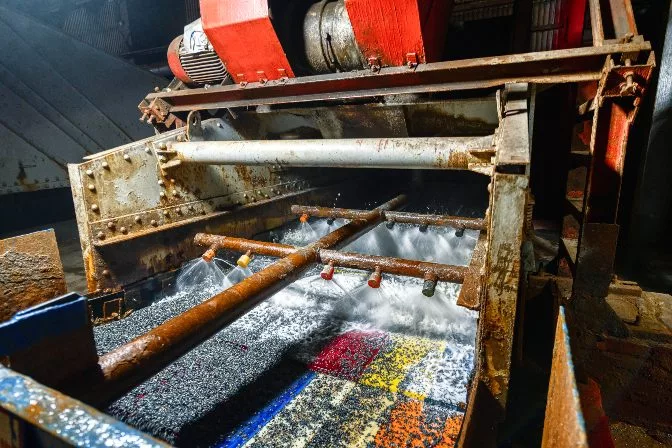

The now smaller materials are fed to screens that size ore, resulting in minerals less than 1.3 cm (½ in) to fall through the screens.

The screening process

The screening process

The smaller ore will go on to the ball grinding mills where they will be further ground down. The larger ore will be routed to a pebble crusher to reduce the size to 1.3 cm (½ in) and will return to the SAG mill stage.

The ball mill product is pumped to cyclones which separate out the coarse material with the fine ore. The coarse mineral ore is routed back to the ball mill stage while the fine minerals are routed to the concentration stage of mining.

Minerals adhere to bubbles in the froth flotation concentration process

Minerals adhere to bubbles in the froth flotation concentration process

During the concentration stage, a cleaner and higher concentration of the desired mineral is produced and ground down to the consistency of talcum powder. This is sent to a thickener where the concentrate settles and dewatering begins.

At this point, the ore is still at about 50% water, so this material is pumped to a filter press to further dewater the mineral ore.

Finally, the minerals are dried to remove the remaining water. The final concentrated mineral percentage differs depending on the mineral and the concentration process used.

The crude material is transferred to another off-site processing plant that smelts or refines the mineral ore into the final raw material.