RANEY NICKEL

Is comprised of mixing Nickel and aluminum to form a ( porus alloy )

two metals bondong yet reacting to form more volumous porus spaces

which inturn affords more metal contact points in aqueous solutions.

Here's another interesting ( heinz 57 porus alloy )

which shows much promise for - hydrogen production

If wellgreen has abundant chloride + nickel silicate

chances are = solid solution nickel =

nickel chloride metallic silicide alloy The research team manufactured FeNiSi in two steps. First, natural clay magadiite, a source of silicon, iron chloride and nickel chloride were heated under pressure to create a ferric-nickel silicate. The ferric-nickel silicate was then combined and heated with magnesium and sodium chloride (table salt) to develop the ordered structure of the FeNiSi alloy. Importantly, this was the first time a metallic silicide alloy had been manufactured using this type of chemical reaction using metallic silicates as a reaction material.

Electron microscopy and X-ray characterization techniques revealed that the manufacturing process created many pore structures in the final FeNiSi alloy, increasing its surface area and overall electrocatalytic performance. The FeNiSi alloy lowers the potential required to split oxygen and hydrogen from water by 308 mV for the oxygen evolution reaction (OER) and 386 mV for the HER, respectively, at a current of 10 mA·cm−2. The electrocatalyst also demonstrated sufficient durability after 15 hours of use.

The research team looks forward to FeNiSi and other transition metal silicates contributing to the synthesis of clean hydrogen gas for future energy needs.

"This work not only provides an easy method for the synthesis of intermetallic silicide with considerable porous structures but also allows the intermetallic silicide to be considered as a bifunctional electrocatalyst for EWS. Low-cost and efficient intermetallic silicide electrocatalysts will provide new opportunities for… renewable energy conversion," said Zhang.

https://phys.org/news/2023-11-durable-inexpensive-electrocatalyst-generates-hydrogen.html 300 milli Volts = 0.3 Volts

Very little energy needed for hydrogen / oxygen evolution

Supposing only wellgreen's sulphide ores are measured.

If we pull forward 2023 pfs payable metals, just how good is the extraction ?

If wellgreen has more lateritic ores and ss nickel upto 0.40%

Then... would it not be more advantageous to mine the silicates ?

Suppose there is a total of, 1,500,000,000 raw tonnes

If we minus 1/3 = 437 million tonnes ( current resource )

and minus another 500 m as waste

= 500 million tonnes remaining

If we use the example of 50% recovery from 0.40% ss Ni

= 0.20% Ni

500 million t

x 0.20 % Ni

=

1,000,000 t

x 2200 lb conversion

= 2.2 billion lbs ( no eq pgm )

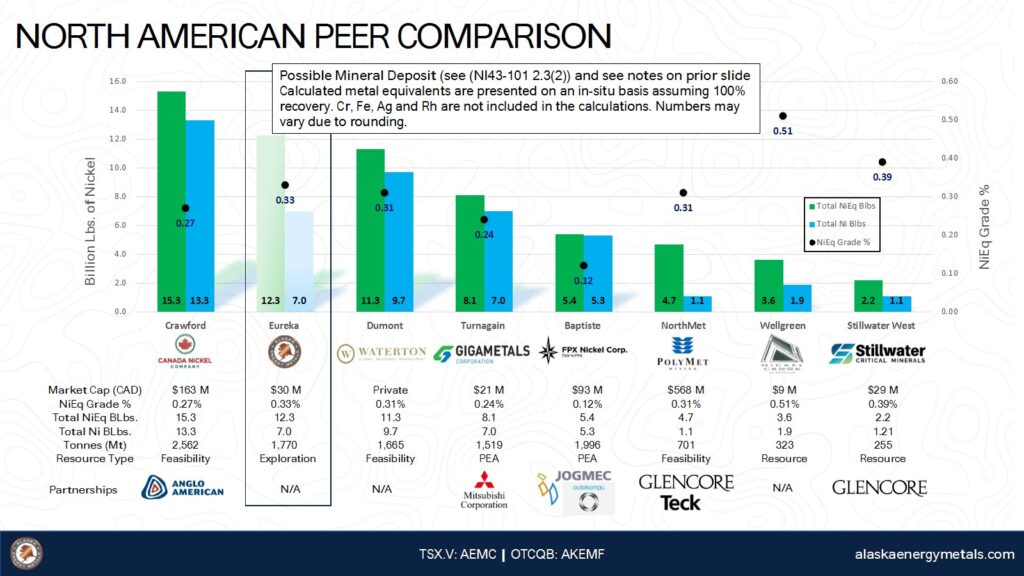

+ 3.6 billion Ni eq current resources +/- = 5.8 billion lbs Ni eq ( potential if nickel silicate were saught ? )

This is not factoring deeper drill intercepts or sulphide mtn expansion capability

that resides outside the current pit shell #4

yet... sulphide mountain lands in, pit #5 If silicate nickel were factored would wellgreen surpass Polymet ?

How much nickel has been mined in Sudbury since inception ?

= 8 million tonnes

SUDBURY

Sep 10, 2021 — The district has produced more than 8 million tonnes Wellgreen cheap open pit

vs Sudbury expensive underground

Question is asked,

could wellgreen be a 2nd Sudbury ?

Nickel Chloride 24% = $8,500 usd

The Nickel Chloride price in United States decreased during Q4 2022 to

8,600 USD per metric ton Could wellgreen set up a second operation and create a 90% nickel chloride ( dry )

and ship to sudbury ?

Sell it to Sudbury for, $3,000/t

Sudbury converts to nickel alloy = $16,400 t

Forward contract

set min $3,000 t

if nickel spot rises $3,000 t increases accordingly

Prospers Sudbury's nickel infastructure + city = for many decades

Ideas.

Good ideas.

Far better than cheap concentrates.

Using the discounted $3,000 t nickel chloride in a revised pfs look like ?