CPM Group’s HPMSM and HPEMM price forecast, as upside case, shows after-tax NPV8% increasing further to US$1.79 Billion, IRR of 24.1%

VANCOUVER, British Columbia, July 27, 2022 (GLOBE NEWSWIRE) -- Euro Manganese Inc. (TSX-V and ASX: EMN; OTCQX: EUMNF; Frankfurt: E06) ("Euro Manganese", the "Company" or "EMN") is pleased to release highlights of its completed Feasibility Study ("FS" or "Study") for the Company’s flagship Chvaletice Manganese Project ("CMP" or "Project") located in the Czech Republic.

All financial figures are in US dollars unless otherwise stated.

HIGHLIGHTS

- Robust base case project economics

- After-tax Net Present Value ("NPV") of US$1.34 billion and pre-tax NPV of US$1.75 billion, using an 8% real discount rate and risk-adjusted base case price forecast.

- Ungeared after-tax Internal Rate of Return ("IRR") of 21.9% with a 4.1-year payback period; and pre-tax IRR of 24.9% with a 3.6-year payback period.

- Initial capital ("Capex") of US$757.3 million, including contingencies of US$103.2 million (US$78.4 million on direct costs and US$24.8 million of growth capital).

- Sustaining capital ("Sustaining Capex") of US$117.0 million over the 25-year life of project ("LOP").

- LOP revenues of US$13.9 billion with gross revenues expected to average US$554 million per year over the 25-year project life.

- Project earnings before interest, taxes, depreciation and amortization ("EBITDA") and annual average EBITDA forecasted to be US$8.1 billion and US$326 million respectively, averaging 58.8% EBITDA over the LOP.

- Project of strategic importance to Europe with exceptional environmental and social benefits and production of in-demand products

- Uniquely positioned to provide a secure, traceable, and responsibly produced supply of high-purity manganese products to the European electric vehicle ("EV") market.

- CMP is the only sizable, Proven and Probable Reserve of manganese in the European Union.

- Located in the Czech Republic, a sophisticated, stable, and business-friendly jurisdiction that is highly supportive of new, green investments.

- Excellent transportation, energy and community infrastructure, and land for the processing plant and related infrastructure.

- Unique green project credentials with a low carbon footprint and net positive environmental benefits resulting from recycling and remediation of the Chvaletice historic tailings.

- Significant support from local communities, municipalities, the Czech government, and the European Union.

- Wide-ranging benefits for local communities and the Czech Republic in the form of jobs and revenues:

- The Project expects to employ ~400 people during operation.

- An estimated US$1.5 billion in payments are expected to be made to the Czech Republic from corporate taxes and royalties.

- High Purity Manganese market forecasted to increase significantly over the life of Project

- According to CPM Group LLC ("CPM Group"), a leading, independent commodities market research firm with expertise in high-purity manganese, the market for high-purity manganese sulphate monohydrate ("HPMSM") and high-purity electrolytic manganese metal ("HPEMM") is forecast to be radically transformed as a result of the ‘electric vehicle revolution’. Most lithium-ion batteries that power electric vehicles are expected to use manganese ("Mn") in their cathodes and these manganese-containing battery chemistries are expected to dominate the battery market for the next two decades.

- As a result, CPM Group expects the demand for high purity manganese to increase 13 times between 2021 and 2031 (from 90 kt to 1.1 million tonnes ("t") of Mn contained) and 50 times between 2021 and 2050 (to 4.5 million tonnes of Mn contained).

- The total Mn market in 2022 is approximately 22 million tonnes, with Mn use currently dominated by the steel industry, however, high purity manganese suitable for the battery market makes up less than 0.5% of the global manganese market.

- The bottleneck in supply of HPMSM and HPEMM is the lack of high-purity refining capacity. Known expansions and new projects are unable to satisfy this demand. CPM Group forecast’s the 2031 deficit to be 475kt Mn equivalent and if battery demand continues to grow as expected and no additional new projects come to the market, the deficit would increase to 1 million tonnes by 2037.

- European HPMSM and HPEMM base case pricing with further potential upside outlined in sensitivity analysis

- Base case project economics are based on Tetra Tech Canada Inc.’s ("Tetra Tech") adoption of a risk-adjusted short-term price forecast that follows CPM Group’s forecast for HPMSM and HPEMM to 2031 and then holds prices flat over the remaining LOP, resulting in average prices of $4,019 per tonne of HPMSM containing 32.34% Mn and $10,545/t of HPEMM containing 99.9% Mn.

- CPM Group’s unaltered price forecast was used as the upside case in the sensitivity analysis with average LOP prices of $4,509/t for HPMSM and $12,075/t for HPEMM.

- Attractive proposition for potential financial partners

- Euro Manganese recently appointed Stifel Nicolaus Europe Limited, a wholly owned subsidiary of Stifel Financial Corp. (NYSE:SF) ("Stifel"), as financial adviser to assist with the structuring and securing of financing for the Project.

- The Company believes the FS confirms that the Project is an attractive proposition for potential financial partners due to its robust project economics, in-demand products, unique environmental credentials, excellent jurisdiction located in the heart of European EV market, and strong support from leading financial European institutions.

- Conversion rate of ~99% Resources to Reserves supports a 25-year project life

- Tetra Tech used appropriate modifying factors to convert the Mineral Resource to a 27 million tonne Proven and Probable Reserve (98.3% Proven) with a grade averaging 7.41% Mn.

- Study is based on the reprocessing of historic tailings without the requirement of any hard rock mining, crushing or milling.

- FS outlines a 25-year project life producing 1.19 million tonnes of HPEMM, approximately two-thirds of which is expected to be converted into HPMSM on-site.

- Saleable product includes 2.5 million tonnes of HPMSM (32.34% Mn) and 372,300 tonnes of HPEMM (99.9% Mn) over the LOP, averaging 98,600 tonnes of HPMSM and 14,890 tonnes of HPEMM annually, focused principally on Europe's rapidly growing EV battery industry.

- Flexibility to supply either HPMSM or HPEMM, to suit customer preference.

Dr. Matthew James, Euro Manganese’s President and CEO, commented:

“I am extremely pleased with the results of the Feasibility Study, which further validate the financial credibility of the Chvaletice Manganese Project, even in the current inflationary environment and using conservative risk-adjusted pricing for HPMSM and HPEMM. The strength of the Project economics, its green credentials and the forecast demand from the EV industry for our highly specialized products support a wide range of financing alternatives.

Several factors uniquely position Euro Manganese to transform into a leading supplier to the European EV market. The supply security, traceability, sustainable production, and low impurity, high quality nature of Chvaletice’s battery grade manganese products, make our HPEMM and HPMSM increasingly desirable to customers.

I am proud of the team’s accomplishments in delivering this very positive Feasibility Study and confirming the viability of the Project. We remain focused on progressing our key milestones towards making a final investment decision, including securing our financing package for the Project, and have already commenced work alongside our recently appointed project finance adviser, Stifel Nicolaus Europe Limited.”

Mr. John Webster, Chair of the Board of Euro Manganese, commented:

“The global automobile industry has been transformed in recent years with manufacturers focused on the transition to electric vehicles. This focus has not only resulted in an increased demand for battery raw materials, but specifically for those sourced from a sustainable and responsible supply chain. At the same time, manganese has emerged as a key component in the dominant formulations of lithium-ion batteries. This has created an unprecedented opportunity for us.

The Chvaletice Project is a key pillar in ensuring the security of supply for Europe’s EV industry. Our strategic location in the Czech Republic, central to an emerging cluster of electric vehicle plants and a related ecosystem of chemical, cell and battery producers, our 25-year operating life, and our commitment to the responsible production of high-purity manganese products, has attracted the attention of lithium-ion battery, battery precursor and cathode makers from around the world.

The completion of our Feasibility Study is a significant milestone for Euro Manganese and moves us a step closer to bringing the Chvaletice Manganese Project into production.”

FEASIBILITY STUDY SUMMARY AND PROJECT ECONOMICS

The following table summarizes the material assumptions used in and the results of the FS, assuming a targeted start of production in 2027. Plant commissioning is anticipated to commence in 2026.

Table 1: Summary of Chvaletice Feasibility Study (Base Case)

| Metrics |

Units |

Results |

| Project Summary |

|

|

| Type of operation |

|

Tailings reprocessing |

| Life of Project (“LOP”) |

Years |

25 |

| Price Assumptions - average LOP (2027-2051) |

|

|

| High purity manganese sulphate monohydrate (“HPMSM”) |

$/tonne |

4,019 |

| High-purity electrolytic manganese metal (“HPEMM”) |

$/tonne |

10,545 |

| Production |

|

Average Annual |

LOP |

| Total tailings extracted & processed |

Dry Kt |

1,066 |

26,644 |

| Total manganese grade |

% |

7.41 |

7.41 |

| Contained manganese (Mn) |

Kt |

78.9 |

1,973.5 |

| Total HPEMM produced |

Kt |

47.8 |

1,194.5 |

| HPEMM further processed into HPMSM |

Kt |

32.9 |

822.3 |

| HPEMM sold |

kt |

14.9 |

372.2 |

| HPMSM produced / sold |

Kt |

98.6 |

2,465.0 |

| Total Mn contained in HPEMM & HPMSM |

Kt |

46.8 |

1,171.9 |

| Overall total Mn recovery |

% |

59.4 |

59.4 |

| Revenues |

|

Average Annual |

LOP |

| Revenue from HPEMM |

$M |

157 |

3,931 |

| Revenue from HPMSM |

$M |

397 |

9,931 |

| Total revenue |

$M |

554 |

13,862 |

| Operating Costs (per tonne of dry plant feed) |

|

|

| Tailings extraction |

$/t |

2.44 |

| Magnetic separation, HPEMM & HPMSM processing |

$/t |

143.18 |

| Tailings stacking/storage, site services, land rentals, and water treatment |

$/t |

27.11 |

| General & Administrative |

$/t |

12.79 |

| Contingency |

$/t |

9.28 |

| Site operating costs |

$/t |

194.79 |

| Freight and insurance, and selling costs |

$/t |

15.22 |

| Czech government royalty(1) |

$/t |

4.53 |

| Total operating costs |

$/t |

214.54 |

| Capital Costs and Working Capital |

|

|

| Initial capital |

$M |

757.35 |

| Sustaining capital over Life of Project |

$M |

117.0 |

| Initial working capital(2) |

$M |

78.7 |

| Project Economics |

|

Pre-Tax |

After Tax |

| NPV (8% real discount rate) |

$M |

1,750 |

1,342 |

| IRR |

% |

24.9 |

21.9 |

| Payback period, from start of processing |

Years |

3.6 |

4.1 |

| Cumulative cash flow, undiscounted |

$M |

7,309 |

5,912 |

Notes:

- Czech government royalty is 2,308 Czech Koruna (CZK) per tonne of Mn produced, translated to USD at a projected CZK to USD exchange rate of 22.43.

- Initial working capital represents the build up of $29.1 million in inventory and $49.6 million in receivables over the course of the first year.

CASH FLOWS

Table 2: Project Revenue, Costs and Cash Flows (Base Case)

| Projected Cash Flows |

Average Annual

($M) |

Life of Project

($M) |

| HPMSM revenue |

397.2 |

9,931.2 |

| HPEMM revenue |

157.2 |

3,930.9 |

| Gross revenues |

554.5 |

13,862.1 |

| Freight and insurance, and selling costs |

16.2 |

405.6 |

| Czech government royalty |

4.8 |

120.6 |

| Net revenues |

533.4 |

13,335.9 |

| Site operating costs |

207.6 |

5,190.1 |

| Capital costs (initial, sustaining and demolition less salvage value) |

33.5 |

836.4 |

| Projected cash flow (pre-tax) |

292.4 |

7,309.4 |

| Corporate taxes |

55.9 |

1,397.4 |

| Undiscounted cash flows |

236.5 |

5,912.0 |

The Czech corporate income tax rate is 19%. In addition to the royalty of CZK 2,308 per tonne of unit Mn produced, the Czech Republic has various payroll and other taxes. The Company has modeled the economics of the Project conservatively from a tax perspective, with a full tax burden, based on Czech legislated tax rates.

For a detailed table of cash flows, please see Appendix 2.

HPMSM and HPEMM PRICING

HPMSM and HPEMM pricing used in this FS is based on price projection assumptions developed by CPM Group, a leading, independent commodities market research firm, with expertise in high-purity manganese.

CPM Group’s price forecast for HPMSM and HPEMM was driven by supply and demand dynamics. Factors taken into consideration of CPM Group’s analysis include:

- A significant increase in forecasted demand for HPMSM and HPEMM markets, resulting from an estimated 30-fold increase in the use of manganese in lithium-ion batteries for electric vehicles between 2021 and 2036;

- A project supply pipeline with six non-Chinese HPMSM projects potentially coming on stream by 2030, plus an assumption of supply coming from recycling batteries and an increase in Chinese supply; and

- A deficit in 2031 of 475kt Mn equivalent. If battery demand continues to grow as expected and no additional projects come to the market, the deficit would increase to 1 million tonnes by 2037.

CPM Group calculated a European HPMSM price based on the Chinese HPMSM price plus the cost of transportation to Europe (sea freight and land transport), import duties (currently suspended), and premiums for purity, traceability and ESG credentials. CPM Group’s estimate puts these European premiums at 15-25% of the Chinese HPMSM price. It should be noted that published HPMSM prices cover many different purities of the product traded, much of which is unable to meet European EV battery producers’ specifications.

Current HPEMM pricing is based on EMM being predominantly a metallurgical market metal, however HPEMM is expected to become predominantly a battery market metal in the near future as this metal can be converted into HPMSM. CPM Group estimates that the demand for HPEMM will significantly increase, leading to competition for supply between the metallurgical industry and a significantly larger battery industry with a supply deficit. Therefore, future HPEMM pricing is forecast to be derived from the HPMSM price as set by the EV battery industry rather than set by the metallurgical market.

This price differential between battery market grade HPEMM and HPMSM is estimated to equate to the cost of conversion of metal into sulphate, plus the profit of the converter, plus an element of amortization of the converter’s capital expenditure incurred when building the dissolution plant, conservatively estimated to be a total of approximately $2,000/mt of metal. Therefore, this differential is subtracted from the European price of HPMSM, on a metal basis, to provide a European price of HPEMM.

Base Case vs Upside Case Pricing

Tetra Tech adopted a risk-adjusted, short-term forecast for the base case price used in this FS that follows CPM Group’s forecast for HPMSM and HPEMM to 2031 and then holds prices flat over the remaining LOP.

The upside case uses CPM Group’s unaltered forecast, which increases pricing through to 2035, then holds prices flat between 2035 and 2040, recognising that a price will be reached which would stimulate additional supply in a growth market. Based on potential additional supply, CPM Group assume prices begin to fall after 2040, despite a continually growing market.

Table: 3 Base Case vs Upside Case Pricing (1) by Product

|

Base Case Pricing |

Upside Case Pricing |

| Year |

HPMSM

($/t) |

HPEMM

($/t) |

HPMSM

($/t) |

HPEMM

($/t) |

| 2027 |

3,266 |

8,197 |

3,266 |

8,197 |

| 2028 |

3,542 |

9,058 |

3,542 |

9,058 |

| 2029 |

3,810 |

9,893 |

3,810 |

9,893 |

| 2030 |

3,873 |

10,091 |

3,873 |

10,091 |

| 2031 |

4,094 |

10,780 |

4,094 |

10,780 |

| 2032 |

4,094 |

10,780 |

4,366 |

11,630 |

| 2033 |

4,094 |

10,780 |

4,658 |

12,541 |

| 2034 |

4,094 |

10,780 |

4,970 |

13,515 |

| 2035 – 2040 |

4,094 |

10,780 |

5,399 |

14,855 |

| 2041 |

4,094 |

10,780 |

5,120 |

13,984 |

| 2042 |

4,094 |

10,780 |

5,000 |

13,609 |

| 2043 |

4,094 |

10,780 |

4,760 |

12,860 |

| 2044 |

4,094 |

10,780 |

4,580 |

12,298 |

| 2045 |

4,094 |

10,780 |

4,400 |

11,736 |

| 2046 |

4,094 |

10,780 |

4,220 |

11,174 |

| 2047 |

4,094 |

10,780 |

4,040 |

10,612 |

| 2048 |

4,094 |

10,780 |

3,980 |

10,425 |

| 2049 |

4,094 |

10,780 |

3,920 |

10,238 |

| 2050 |

4,094 |

10,780 |

3,860 |

10,050 |

| 2051 |

4,094 |

10,780 |

3,860 |

10,050 |

Notes:

- The prices in Table 3 are real prices (i.e. excluding inflation) as at 2021.

PROJECT SENSITIVITY ANALYSIS

A detailed sensitivity analysis for the Chvaletice Manganese Project was completed to determine the effects of key variables in relation to the after-tax NPV of $1.34 billion at a discount rate of 8%. The results of the sensitivity analysis are presented in Tables 4 and 5 below.

As discussed above, Tetra Tech adopted a risk-adjusted, short-term forecast of CPM Group’s pricing for the base case. The upside case is based on CPM Group’s unaltered forecast prices. The downside prices are the same average price differences, in the reverse direction, between the short term (base case) and the unaltered CPM Group forecast (upside case). This results in -12.3% from the base case for HPMSM and -14.9% for HPEMM for the downside case.

Table 4: Selected Financial Metrics based on Price Sensitivities

| Metrics |

Units |

Downside Case |

Base Case |

Upside Case |

| HPMSM price (average LOP) |

$/t |

3,524 |

4,019 |

4,509 |

| HPEMM price (average LOP) |

$/t |

8,974 |

10,545 |

12,075 |

| Post-tax undiscounted cashflow |

($B) |

4.46 |

5.91 |

7.37 |

| Post-tax NPV 6% |

($B) |

1.35 |

1.92 |

2.51 |

| Post-tax NPV 8% |

($B) |

0.90 |

1.34 |

1.78 |

| Post-tax NPV 10% |

($B) |

0.59 |

0.93 |

1.27 |

| IRR |

(%) |

18.1 |

21.9 |

24.1 |

| Payback period |

(years) |

5.0 |

4.1 |

4.1(1) |

Notes:

- Payback period for upside case is the same as the base case as upside payback is calculated on forecast pricing which is the same as the base case pricing for the first 5 years of operations (as detailed in Table 3).

Table 5: After-Tax NPV8% Sensitivity Analysis of Initial Capex, Opex and Recoveries

| Sensitivity |

-20%

($/M) |

-10%

($/M) |

Base Case

($/M) |

+10%

($/M) |

+20%

($/M) |

| Initial capital costs |

1,464.5 |

1,403.1 |

1,341.7 |

1,280.3 |

1,218.9 |

| Total operating costs |

1,571.5 |

1,458.0 |

1,341.7 |

1,222.5 |

1,100.6 |

| Recoveries |

914.1 |

1,127.9 |

1,341.7 |

1,555.5 |

1,769.3 |

CAPITAL COST SUMMARY

Capital expenditure estimates were prepared for both initial and sustaining capital. A projected summary of scheduled capital costs is shown in Appendix 2.

The expected initial capital expenditures for the Project, inclusive of capitalized operating start-up costs, as estimated by Tetra Tech, with inputs from Tractebel Engineering a.s. ("Tractebel"), a Czech local engineering firm, BGRIMM Technology Group (Beijing General Research Institute of Mining and Metallurgy) ("BGRIMM"), Sudop Praha a.s. ("Sudop") a Czech local engineering firm, and EMN/Mangan Chvaletice, s.r.o. ("Mangan"), as of Q2 2022, are $757.3 million, including all development-related costs incurred prior to the envisaged commencement of commercial operations. Initial capital expenditures include $24.8 million of growth capital, a provision for expected cost increases on known expenditures. Contingencies on initial capital expenditures have been added at appropriate percentages to each component of the Project, excluding capitalized operating costs, resulting in an overall contingency of $78.4 million or 15.6% of direct costs. Capital costs incurred after start-up are assigned to sustaining capital and are projected to be paid out of operating cash-flows (see Table 6).

Table 6: Capital Cost Estimate

| Item |

Initial Capital

($M) |

LOP Sustaining Capital

($M) |

| Overall site costs |

57.9 |

- |

| Mining/tailings extraction |

4.6 |

6.1 |

| Processing HPEMM |

295.1 |

28.0(1)

|

| Processing HPMSM, from 99.9% HPEMM |

42.2 |

| Residue Storage Facility |

5.4 |

82.9 |

| Onsite infrastructure |

98.1 |

- |

| Sub-total direct costs |

503.3 |

117.0 |

| Indirect costs |

128.4 |

- |

| Owner’s costs |

47.2 |

- |

| Contingency |

78.4 |

- |

| Total capital costs |

757.3 |

117.0 |

Notes:

- Includes total LOP sustaining capex for processing HPEMM and HPMSM.

Project Infrastructure

The Chvaletice Manganese Project is located approximately 90km east of Prague in the Czech Republic, and is served by excellent existing infrastructure, including rail, highway, a gas pipeline, and water supply systems, and is adjacent to an operating power plant. The proposed plant site is zoned for industrial use and is the site of the former process plant that produced the Chvaletice tailings.

New and refurbished infrastructure that will be built to service the Project include: a tailings excavation and handling facility; a south and north site connection utility bridge for transporting tailings slurry, return water pipes and the tube conveyor that returns a mixture of non-magnetic tailings and washed leach residue to the residue dry stacking area; enclosed and winterized process plant buildings and various reagent storage facilities and product warehouse; an upgraded rail spur system with related loading/unloading facilities; an internal road network; an incoming electrical 400kV high voltage grid connection including transformers, GIS switchgear, and local distribution step-down transformers; a process equipment maintenance workshop; a mobile fleet maintenance workshop; spare part and maintenance supply warehouses; a comprehensive water management system, onsite laboratories; and general administrative offices.

OPERATING COST SUMMARY

Onsite operating costs are expected to average $194.79 per tonne plant feed ($4.43 per kg Mn equivalent) with offsite operating costs estimated to average $19.75 per tonne plant feed ($0.45 per kg Mn equivalent), as shown in Table 7.

Table 7: Operating Cost Estimate

| Item |

$/t of Plant Feed |

$/kg of Mn Equivalent |

LOP Total

($M) |

| Mining/tailings extraction costs |

2.44 |

0.06 |

64.9 |

| Magnetic separation and processing to HPEMM |

123.35 |

2.81 |

3,286.6 |

| Processing HPEMM to HPMSM |

19.83 |

0.45 |

528.4 |

| Residue storage, site services and water treatment |

26.12 |

0.59 |

696.0 |

| General & Administrative and other |

13.77 |

0.31 |

367.0 |

| Contingency |

9.28 |

0.21 |

247.2 |

| Sub-total onsite opex |

194.79 |

4.43 |

5,190.1 |

| Freight and insurance, selling costs |

15.22 |

0.35 |

405.6 |

| Czech government royalty(1) |

4.53 |

0.10 |

120.6 |

| Sub-total offsite opex |

19.75 |

0.45 |

526.2 |

| Total operating costs |

214.54 |

4.88 |

5,716.3 |

Notes:

- Czech government royalty is 2,308 Czech Koruna (CZK) per tonne of Mn produced, translated to USD at a projected CZK to USD exchange rate of 22.43.

Power

The Project is expected to consume approximately 490GWhr/year of baseload electrical energy, of which up to two thirds will be required to power the operation of the electrowinning circuit. The Company is actively engaged in procuring a long term, stable supply of renewable, carbon-free electricity for the Project and has engaged the services of Baringa Services Ltd., a UK based power markets forecasting analyst.

Filtered Dry-Stacked Tailings

High pressure filter press technology has been adopted for the washing and dewatering of the tailings and leach residue, which is considered an industry best practice. To realize optimum material strength, several dewatering technologies were tested and evaluated during the FS with the ultimate objective of achieving average moisture content in the 23-25% range for ultimate strength and stability, while minimizing water losses and consumption.

CHVALETICE FEASIBILITY STUDY AND TECHNICAL REPORT

The FS was prepared by Tetra Tech, an independent engineering services group with extensive experience in mineral processing, tailings management and mining. Tetra Tech oversaw the project, the resource and reserve estimates and the design of the mine and residue storage facility. BGRIMM acted as lead process plant design engineer as well as completed validation bench scale test work required in order to finalize the process flowsheet. Tractebel provided Czech and European cost inputs, localization, and GET s.r.o ("GET") and Bilfinger Tebodin Czech Republic ("Tebodin") provided environmental services. Sudop provided railway infrastructure design.

The FS is based on a Proven and Probable Reserve Estimate that will be detailed in the updated National Instrument ("NI") 43-101 Technical Report on the Chvaletice Manganese Project. The NI-43-101 report will include results of the FS and be filed within 45 days of this release on SEDAR at www.sedar.com and made available on the Company’s website. The JORC Technical Report is expected to be lodged with the Australian Securities Exchange ("ASX") within the same time period.

RESOURCE ESTIMATE

Tetra Tech was engaged to oversee the planning and execution of sampling and assaying, to prepare the Resource Estimate for EMN's Chvaletice Manganese Project, to prepare the Technical Report in accordance with NI 43-101 - Standards of Disclosure for Mineral Projects ("NI 43-101"), and to prepare the independent JORC Code technical report in accordance with the Joint Ore Reserves Committee Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves 2012 Edition ("JORC Code"). The 43-101 Technical Report, entitled “Technical Report and Mineral Resource Estimate for the Chvaletice Manganese Project, Chvaletice, Czech Republic”, with an effective date of December 8, 2018 (the "Mineral Resource Estimate"), was filed on SEDAR on January 28, 2019. No additional drilling or data collection pertaining to the technical disclosure of mineral inventory has been undertaken since the completion of the Mineral Resource Estimate, and the effective date for the Mineral Resource Estimate is revised to July 1, 2022. The Project's combined Measured and Indicated Mineral Resources amount to 26,960,000 tonnes, grading 7.33% total manganese as detailed in Table 8 below.

Table 8: Chvaletice Mineral Resource Statement (effective July 1, 2022)

| Historic Tailings Cell |

In-situ Dry Bulk Density

(t/m3) |

Volume

(x1,000 m3) |

Tonnage

(kt) |

Grade Mn

(% total Mn) |

| Cell #1 |

|

|

|

|

| Measured |

1.52 |

6,577 |

10,029 |

7.95 |

| Indicated |

1.47 |

160 |

236 |

8.35 |

| Cell #2 |

|

|

|

|

| Measured |

1.53 |

7,990 |

12,201 |

6.79 |

| Indicated |

1.55 |

123 |

189 |

7.22 |

| Cell #3 |

|

|

|

|

| Measured |

1.45 |

2,942 |

4,265 |

7.35 |

| Indicated |

1.45 |

27 |

39 |

7.90 |

| Total Measured |

1.51 |

17,509 |

26,496 |

7.32 |

| Total Indicated |

1.50 |

309 |

464 |

7.85 |

| Combined Measured + Indicated |

1.51 |

17,818 |

26,960 |

7.33 |

Notes:

- Estimated in accordance with the Canadian Institution of Mining ("CIM") Definition Standards on Mineral Resources and Mineral Reserves adopted by CIM Council, as amended, which are materially identical to JORC Code.

- The Chvaletice Mineral Resource has a reasonable prospect for eventual economic extraction. Mineral Resources do not have demonstrated economic viability.

- Indicated Resources have lower confidence that Measured Resources.

- A break-even grade of 2.18% tMn has been estimated for the Chvaletice deposit based on preliminary pre-concentration operating costs of US$6.47/t feed, leaching and refining operating cost estimates of US$188/t feed, total recovery to HPEMM and HPMSM of approximately 60.5% and 58.9%, respectively, and product prices of US$9.60 kg/t for HPEMM and US$3.72 kg/t for HPMSM (GPM Group Report, June 2022). The actual commodity price for these products may vary.

- A cut-off grade has not been applied to the block model. The estimated break-even cut-off grade falls below the grade of most of the blocks (excluding 5,000 tonnes which have grades less than 2.18% total Mn). It is assumed that material segregation will not be possible during extraction due to inherent difficulty of grade control and selective mining for this deposit type.

- Grade capping has not been applied.

- Numbers may not add exactly due to rounding.

RESERVE ESTIMATE

Mineral Reserves for the Project are based on the Measured and Indicated Resource and adhere to the guidelines set by the Canadian Institute of Mining ("CIM"), NI 43-101 and the CIM Best Practices. Material economic modifying factors were applied to each block in the block model including mined grade, contained metal, recovery rates for HPEMM and HPMSM, mining operating cost, processing cost, (including EMM to MSM conversion cost), residue placement cost, general and administrative costs, site service costs, water treatment, shipping cost, product insurance, and royalties. The Project’s combined Proven and Probable Mineral Reserve amount to 26,644,000 tonnes, grading at 7.41% total manganese as detailed in Table 9 below.

Table 9: Chvaletice Mineral Reserve Statement (effective July 14, 2022)

| Historic Tailings Cell |

In-situ Dry Bulk Density

(t/m3) |

Volume

(x1,000 m3) |

Tonnage

(kt) |

Grade Mn

(% total Mn) |

| Cell #1 |

|

|

|

|

| Proven |

1.51 |

6,651 |

10,132 |

7.83 |

| Probable |

1.52 |

141 |

208 |

8.24 |

| Cell #2 |

|

|

|

|

| Proven |

1.53 |

7,929 |

12,106 |

6.91 |

| Probable |

1.54 |

119 |

183 |

7.35 |

| Cell #3 |

|

|

|

|

| Proven |

1.46 |

2,744 |

3,979 |

7.49 |

| Probable |

1.46 |

25 |

36 |

7.98 |

| Total Proven |

1.50 |

17,325 |

26,217 |

7.35 |

| Total Probable |

1.51 |

284 |

427 |

7.84 |

| Combined Proven + Probable |

1.51 |

17,609 |

26,644 |

7.41 |

Notes:

- Estimated in accordance with the CIM Definition Standards on Mineral Resources and Mineral Reserves adopted by CIM Council, as amended, which are materially identical to the JORC Code.

- The Mineral Resource is inclusive of the Mineral Reserves.

- Probable Reserves have lower confidence than Proven Reserves. Inferred Resources have not been included in the Reserves.

- A break-even grade of 2.18% total Mn has been estimated for the Chvaletice deposit based on preliminary pre-concentration operating costs of $6.47/t feed, leaching and refining operating cost estimates of $188/t feed, total recovery to HPEMM and HPMSM of approximately 60.5% and 58.9% respectively and product prices of US$9.60 kg/t for HPEMM and US$3.72 kg/t for HPMSM (CPM Group Report, June 2022). The actual commodity price for these products may vary.

- Grade capping has not been applied.

- Numbers may not add exactly due to rounding.

- Minimal dilution and losses of <1% are expected to occur at the interface between the lower bounds of the tailings cells and original ground as the surface is uneven.

PROCESSING FACILITIES

Tailings Extraction, Residue Storage Facility and Reclamation

In the tailings extraction plan, the three tailings cells will be excavated in a counter clockwise sequence, starting with Cell #3, followed by Cells #1 and #2. Tailings will be extracted using shovel excavators and hauled by truck to an intermediate re-pulping and a covered storage station located between Cells #1 and #2. The storage station will create a 5-day material stockpile. Re-pulped tailings will be fed to the magnetic separation plant via a slurry pipeline on a continuous basis.

A blend of non-magnetic tailings and washed leach residue materials from the process plant will be conveyed using a tube conveyor to the storage station and placed and compacted in the Residue Storage Facility ("RSF"). The excavated area exposed after extraction of the existing tailings will be lined with a geomembrane liner. The facility will be constructed in stages to suit tailings storage requirements and to minimize the footprint of tailings exposed to the air at any given time.

Design features of the filtered tailings storage facility include a geomembrane lined bottom, perimeter surface water diversion and a contact water collection system that is integrated with the overall site water management system. Dust management includes the implementation of modern dust suppression methods on open faces, interim stack surfaces and haul roads, as required.

Progressive reclamation will be undertaken as an integrated part of the tailings stacking procedure. The tailings stack cover will consist of a low permeability soil and/or geomembrane cover to inhibit erosion and infiltration, and a growth layer to support vegetation growth.

The site is expected to be fully reclaimed and brought back into productive community use to be established in consultation with local communities, regulators and national government agencies. The RSF will be monitored during the post-closure period for geotechnical and environmental performance.

Table 10: Feasibility Study Tailings Extraction, Processing and Production Plan

|

Year 1

2027 |

Year 2

2028 |

Year 3

2029 |

Years 4-25

2030-2051

(Average) |

Total

LOP |

| Tailings milled (kt)(1) |

718 |

1,113 |

1,107 |

1,078 |

26,644 |

| Mn grade (%)(1) |

7.98 |

7.41 |

7.44 |

7.39 |

7.41 |

| Contained Mn (kt) |

57.3 |

82.5 |

82.4 |

79.6 |

1,973.5 |

| HPEMM produced (kt)(2) |

32.1 |

50.1 |

50.1 |

48.3 |

1,194.5 |

| HPEMM converted to HPMSM (kt)(2) |

21.7 |

33.4 |

33.4 |

33.4 |

822.3 |

| HPMSM produced (kt) |

65.0 |

100.0 |

100.0 |

100.0 |

2,465.0 |

| Total Mn production (kt) |

31.5 |

49.1 |

49.1 |

47.4 |

1,171.9 |

| Overall recovery (%)(3) |

55.0 |

59.6 |

59.6 |

59.3 |

59.4 |

Notes:

- Tonnage and grade in Table 10 were calculated by Tetra Tech and includes an overall 0.5% manganese loss factor and no dilution.

- Approximately two-thirds of the annual HPEMM production is converted to HPMSM on site, with the balance being sold as HPEMM.

- The combined overall recovery of manganese from tailings to high purity manganese products is estimated to be 59.4% over the life of the Project, excluding the extraction manganese loss factor of 0.5%. Manganese recoveries in the production of HPEMM and HPMSM are expected to average 60.5% and 58.9%, respectively.

For a production table by year, please see Appendix 2.

High-Purity Manganese Processing Facilities

The processing facilities, including ancillary facilities for HPEMM and HPMSM production from the CMP tailings were designed by BGRIMM together with EMN and Tetra Tech, based on the comprehensive metallurgical test results conducted during the Preliminary Economic Assessment and validated through bench scale tests during the feasibility study. The design work included process circuit and process equipment optimization. Mass, energy, and water balances were simulated and estimated by a combination of METSIM modelling, calculations using results from the metallurgical test work program, and BGRIMM’s experience. Key equipment items were sized and selected by the design team incorporating inputs from potential Chinese equipment vendors.

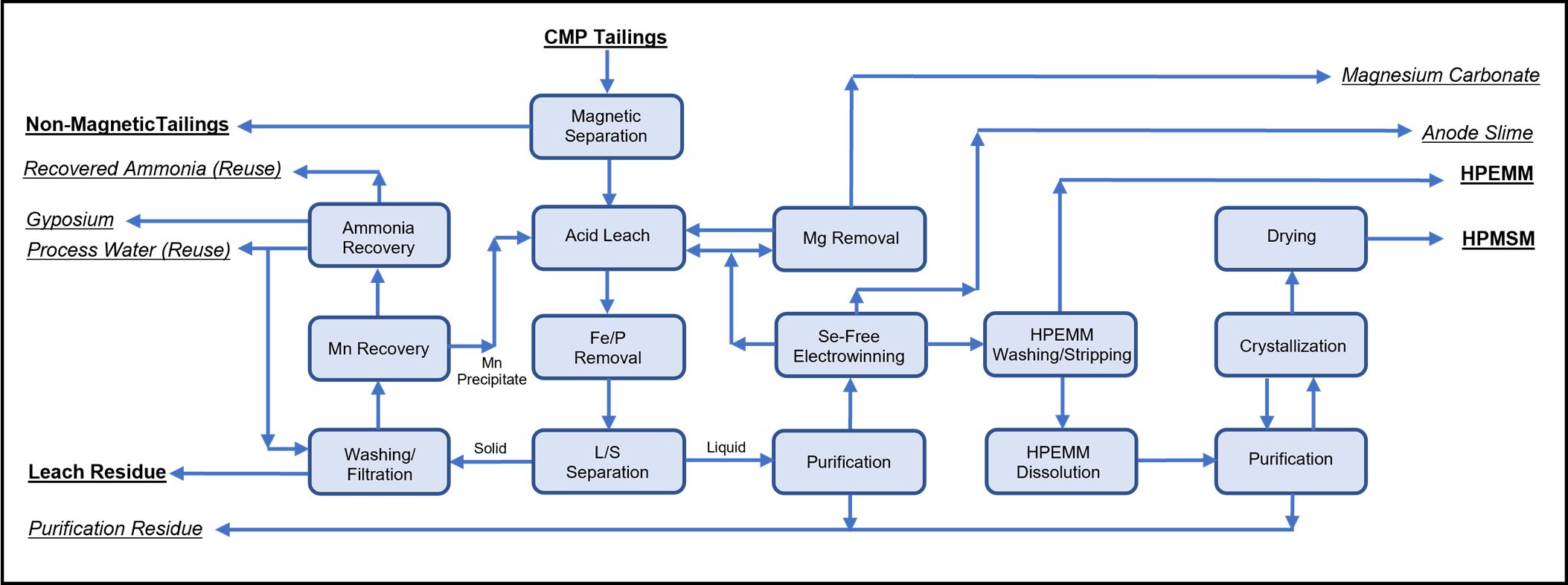

The CMP process plant has been designed to a name plate nominal production capacity of 50,000 tonnes per annum of HPEMM by extracting approximately 1.1 million tonnes of tailings per year. Two-thirds of the annual HPEMM flake production is expected to be converted to approximately 100,000 tonnes per annum of HPMSM (32.24% Mn). This product mix is expected to best meet the high purity manganese market demand anticipated in current and future low-cobalt lithium-ion battery formulations. The HPEMM product containing >99.9% manganese is expected to be sold as flakes and will be produced without the use of selenium and chromium. The CMP HPMSM product is designed to contain no less than 99.9% high purity manganese sulfate monohydrate and a minimum of 32.34% manganese and will be sold in powder form, produced without the use of fluorine. The proposed process flow sheet is illustrated in Figure 1 below.

Figure 1: FS Simplified Process Flowsheet

The major steps in the CMP flow sheet are:

- Excavated tailings will be re-pulped and pumped via a pipeline carried by an overhead bridge that will cross a highway and a railway line and related spurs that adjoin the process plant site located immediately south of the tailings piles.

- The tailings slurry will be upgraded in a wet, high-intensity magnetic separation circuit that upgrades the manganese grade of the leach feed to approximately 15% total manganese and rejects approximately 58% of the feed to non-magnetic tailings, with an expected 86% manganese recovery. The magnetic concentrate and non-magnetic tailings produced will be dewatered using thickeners and filters. The concentrate will be fed to the downstream leach process and the dewatered tailings, together with the washed leach residue will be dry stacked in the RSF.

- The magnetic concentrate cake will be re-pulped and leached using dilute sulfuric acid and residual acid from manganese electrowinning circuit. Neutralization of the slurry will be achieved using hydrated lime. Air sparging of the neutralized slurry will be used to cost-effectively coprecipitate the substantial quantities of impurities that leach with the manganese. The leach pulp will be filtered in automatic pressure filters to separate pregnant leach solution from the leach residue.

- The leach residue will then be washed with process water in an on-stream washing/filtration circuit using pressure filtration prior to co-disposal with the non-magnetic separation tailings in a lined dry-stack tailings storage facility that will be progressively constructed in excavated areas of the CMP tailings cells.

- The wash water from the leach residue washing circuit will be treated for manganese and ammonia recovery to minimize manganese and ammonia losses. The wash water recovery system recovers manganese units to the leaching circuit in the form of manganese carbonate. The spent wash water solution will be treated to recover ammonia using a conventional lime boil process and will produce a gypsum by-product. The recovered ammonia will be reused in the HPEMM production circuits. The inclusion of the leach residue washing circuit with its associated wash water recovery circuit is expected to be a world-leading industry practice for the hydrometallurgical processing of manganese ores. Returning washed tailings to the carefully prepared containment cells in the excavated areas of the tailings progressively remediates the environmental impact risks of legacy mining operations.

- The pregnant solution from the leaching circuit will be purified to remove heavy metals and other impurities and stabilized to prevent uncontrolled crystallization of salts to produce the solution for the downstream electrowinning process.

- Electrowinning will be conducted in electrowinning cells. The tank house will have the capacity to produce 50,000 t/annum HPEMM using an energy efficient and selenium free process. The proposed electrowinning circuit is designed to have a plating cycle of 24 hours at a cell voltage of 4.2 to 4.4 V and an average cathode-current density of 320 to 370 A/m2. Cathodes will be harvested using semi-automatic harvesting machines, washed, and stripped of electrodeposited manganese metal using industry-standard automatic cathode plate stripping machines. Approximately two thirds of the HPEMM flakes will then be used as feed for HPMSM production. The remaining HPEMM flakes will be packed and directly shipped to customers for onsite dissolution and/or the sale of flakes.

- A magnesium removal process has been incorporated into the process plant design to ensure efficient electrowinning operations and high-quality product. The magnesium removal process will maintain the magnesium concentration in the electrowinning solutions at a level that prevents uncontrolled precipitation of salts and scaling. The process uses low cost reagents without incurring significant losses of manganese and reagent units.

- The base case FS production plan proposes to dissolve approximately two-thirds of the HPEMM flakes using sulfuric acid to produce 100,000 t/annum of HPMSM powder in a dust-free chemical processing facility. The dissolved HPMSM solution will be further purified to remove trace impurities carried by the HPEMM flakes. This plant design assumes the feed solution will be concentrated using an energy efficient, low temperature mechanical vapor recompression (MVR) crystallization process to generate a single specification of manganese sulfate monohydrate crystals. The HPMSM crystals will be separated from the saturated crystal slurry using centrifuges. The dewatered crystals will be dried using disc dryers to produce the final HPMSM powder, while the spent feed solution returns to the HPEMM dissolution circuit. The dried HPMSM powder product will be packed prior to being shipped in trucks or containers to customers throughout the EU.

ENVIRONMENT, PERMITTING AND COMMUNITIES

Environmental Baseline Studies

The vicinity around the Chvaletice tailings area has been significantly impacted by past mining and related heavy industrial activities. Mining activity at Chvaletice ended in 1975. Czech law exempts landowners and developers from impacts prior to 1989, when communism ended in then Czechoslovakia.

Since 2017, GET, a Czech mining, geological and environmental services firm, has produced several studies for the Project, including environmental baseline studies. These included ecosystem mapping, documentation of the physical and environmental characteristics of the CMP site and an assessment of land use plans of the adjoining municipalities. Significant local features were recorded, including sensitive and protected areas, vegetation, landscape elements, and areas or sites of historical, cultural, archaeological or geological importance. Climate, air, water, soil, natural resources, fauna, flora and ecosystems, landscape and population of the area were inventoried. The baseline studies provide an overall assessment of the environment conditions that prevail in the Project area.

Due to the location of the CMP on the shore of the Labe River and overlying a shallow aquifer in the Labe Valley, there are environmental sensitivities related to ongoing tailings runoff and impacts to local groundwater. Currently, EMN has knowledge of impacted groundwater caused by the historical mining and processing activity in the area, particularly the ongoing leaching of metals from the tailings. The Company continues to regularly monitor these impacts in groundwater wells. The Company expects that its proposed reprocessing and remediation of the historic Chvaletice tailings will result in halting ongoing groundwater pollution caused by the existing unlined tailings facility.

Environmental and Social Impact Assessment

In 2019-2020, Bilfinger Tebodin Czech Republic conducted the Preliminary Environmental and Social Impact Assessment ("PESIA" or "EIA Notification") as the first stage of environmental assessment of the Project. Several detailed expert studies were prepared including a comprehensive site wide Biological Survey, a detailed Air Dispersion model and Study, an Acoustic/Noise Impact Study, a Road and Rail Transportation Study, a site wide Hydrogeological Survey, a Health Impact Assessment, an Impact on Landscape Character study and a Reclamation and Remediation Study. A screening decision summarizing all received comments on the Company’s EIA Notification was published by the Ministry of Environment ("MoE") in December 2020.

No crucial objections and comments were raised within the first phase of the project's environmental impact assessment (screening procedure). Requirements arising from the first stage of environmental and social assessment were incorporated into the FS and Project Design.

The second and final stage of the Project’s Environmental and Social Impact Assessment ("ESIA") is being concluded and is expected to be submitted to the Czech MoE in September 2022. The ESIA will include a detailed description of:

- The manganese production process and resulting environmental footprint of the Project;

- Results of baseline and other studies conducted to date;

- Health, safety and environmental management plans;

- Impact assessment, impact mitigation and avoidance plans/measures;

- Socio-economic impacts on local communities;

- Reclamation plans/objectives; and

- Acoustic and dispersion modeling results.

Permitting

The Czech firm, GET has provided localization services for EMN that identified local requirements and permits required for the CMP. Other work included a review of local regulatory requirements for the permitting process and a review of Czech environmental regulations, standards and environmental practices, including wastewater, waste and tailings storage, air, noise and other regulations.

Community Engagement

EMN has pro-active and regular consultation with community stakeholders, which is expected to intensify as the CMP advances. The Company’s subsidiary, Mangan operates a Project Information Center in the Town of Chvaletice’s Municipal Culture House, to provide residents with opportunities to learn about the CMP, aid in developing relationships with the Company, and to provide feedback and suggestions during Project development. Mangan’s registered office is also located in Chvaletice, a step towards ultimately basing its Czech head office in this municipality, close to operations.

Benefits to Stakeholders

- The Project results in the remediation of a historic mine site, where metals and other compounds currently leach into the groundwater. As extraction, reprocessing and proper disposal of the Chvaletice historic tailings is carried out, the site will be progressively rehabilitated to be in compliance with Czech and European environmental requirements.

- The Company has extensively engaged and plans to continue meaningful consultation with local residents, communities, organizations and regulatory agencies, soliciting active local participation and input in the Project’s evaluation and planning process.

- Since the inception of the Project, the Company has sought out, trained and helped to develop numerous talented Czech professionals. EMN expects that the Project would employ mostly local people during construction and operations.

- During the 25-year life of project, benefits to the Czech State and local communities would include the employment of approximately 400 people and an estimated $1.5 billion in revenues generated from corporate taxes and royalties.

NEXT STEPS

With the Feasibility Study now complete, the Company continues to focus on the key milestones to enable a final investment decision, which include:

- Submission of the ESIA to the Czech MoE, expected this quarter, followed by its approval targeted in the first half of 2023;

- Rezoning of the remaining land area underlying the tailings for mining use, which the Company anticipates being approved by the Municipality of Chvaletice by the end of 2022;

- Negotiating and completing the remaining land agreements, which would provide access to the outstanding 70% of the total land area required for the Project;

- Entering a contract to provide engineering, procurement, construction management ("EPCM") support to the Project;

- Executing binding offtake agreements for EMN’s high-purity manganese products to support project financing; and

- Developing an optimum financing structure for the Project, which is dependent upon the above milestones being achieved.

There is the risk that certain of the above key milestones may take longer than expected, or the Company may not be able to achieve certain milestones, which could materially delay or affect the success of the Project.

PROJECT FINANCING

Euro Manganese recently appointed Stifel as financial adviser to assist with the structuring and securing of financing for the Project of $757.3 million as well as a working capital facility. The FS confirms several factors, outlined below, that make the Project an attractive proposition for potential financial partners. Consequently, the Company has reasonable grounds to assume that it will be able to fund the development of the Project.

- Robust project economics – the FS outlines strong project economics at base case, with long project life and sufficient operating margin to sustain debt financing.

- In-demand products – as the only sizable manganese resource in Europe, the Project provides a fully-traceable and secure supply of high-purity manganese products for European cathode makers, battery makers, and automotive OEMs.

- Unique environmental credentials – the reprocessing and rehabilitation of historic tailings results in net positive environmental benefits to water and soil quality over the life of the Project and the Project’s low carbon footprint also contributes to responsibly produced HPEMM and HPMSM, a sought-after attribute as automotive manufacturers use strategic procurement to meet their targets of lower emissions across their supply chains. The Company has conducted a Life Cycle Assessment that quantifies the Project's environmental impacts, the results of which are expected to be received and released soon.

- Excellent jurisdiction – located in the heart of Europe, in a stable and business-friendly jurisdiction, the Project is well-positioned to capitalize on the growth in the European EV market.

- Strong support from leading European institutions – the Company has existing relationships with European financial institutions, some of which are already strategic investors in EMN, who have expressed interest in being potential cornerstone debt providers subject to due diligence.

COMPENTENT AND QUALIFIED PERSON(S) STATEMENT

All production targets for the Chvaletice Manganese Project referred to in this news release are underpinned by estimated Proven and Probable Reserves prepared by Competent Persons and Qualified Persons in accordance with the requirements of the JORC Code and NI 43‐101, respectively. Additionally, the scientific and technical information included in this news release, is based upon information prepared and approved by Mr. James Barr, P. Geo, Senior Geologist, Mr. Jianhui (John) Huang, Ph.D., P. Eng., Senior Metallurgical Engineer, Mr. Hassan Ghaffari, P.Eng, M.A.Sc., Senior Process Engineer, Mr. Chris Johns, P.Eng, Senior Geotechnical Engineer, Davood Hasanloo, P.Eng, M.A.Sc., Senior Hydrotechnical Engineer, and Mrs. Maurie Marks, P.Eng, Senior Mining Engineer, all with Tetra Tech and Ms. Andrea Zaradic, P. Eng., Vice President Operations for Euro Manganese. Mr. Barr, Mrs. Marks, Mr. Ghaffari, Mr. Johns, Mr. Hasanloo and Mr. Huang are consultants to, and independent of, EMN within the meaning of NI 43-101, and have sufficient experience in the field of activity being reported to qualify as Competent Persons as defined in the JORC Code, and are Qualified Persons, as defined in NI 43-101. Mr. Barr is responsible for the Mineral Resource Estimate and data verification, Mr. Huang is responsible for the metallurgical test work results, process engineering, operating cost and capital cost estimates, Mr. Ghaffari is responsible for infrastructure, Mr. Hasanloo is responsible for mine site water management and overall site water balance, Mrs. Marks is responsible for conversion of the Mineral Resources to Mineral Reserves, and mining and financial analysis, Mr. Johns is responsible for design of the residue storage facility, and Ms. Zaradic is responsible for environmental studies, permitting, and social or community impact. Mr. Barr verified the data for the resource estimate, and other qualified persons verified data for their responsible sections. Mr. Barr visited the property during the 2017 drilling program and again during the 2018 drilling campaign, on July 30-31st, 2018, during which time he observed the drilling, sample collection and preparation, sample logging and sample storage facilities. Mr. Huang visited the Project on February 5, 2018 and May 2022, as well as visited the Changsha Research Institute for Mining and Metallurgy (“CRIMM”) laboratory and pilot plant facility five times between January 20, 2017 and September 20, 2018 to witness sample preparation and test/assay facilities and to discuss the test program and results with CRIMM’s technical team. Mr. Huang also visited the SGS Minerals Services (SGS) laboratory on June 29, 2017 and visited BGRIMM’s laboratory four times between September 3, 2019 to January 25, 2020. Mr. Huang oversaw the bench scale validation test work and discussed test work program and results with BGRIMM’s technical team. Mrs. Marks, Mr. Johns and Mr. Ghaffari also visited the project site in May 2022. Ms. Zaradic visited the project site in April 2019 and May 2022.

Messrs. Barr, Huang, Ghaffari, Johns, Hasanloo and Mrs. Marks have no economic or financial interest in the Company and each consent to the inclusion in this news release of the matters based on their information in the form and context in which it appears.

In addition, technical information concerning the Chvaletice Manganese Project is reviewed by Ms. Andrea Zaradic, P. Eng, VP Operations for Euro Manganese, and a Qualified Person under NI 43-101. Ms. Zaradic has reviewed and approved the information in this news release for which she is responsible and has consented to the inclusion of the matters in this news release based on the information in the form and context in which it appears.

NON-IFRS MEASURES

The Company has included certain non-IFRS performance measures as detailed below. These are common performance measures but may not be comparable to similar measures presented by other issuers and the non-IFRS measures do not have any standardized meaning. Accordingly, it is intended to provide additional information and should not be considered in isolation or as a substitute for measures of performance prepared in accordance with IFRS.

EBITDA - Earnings before interest, taxes, depreciation and amortization is a measure of profitability and includes the Company’s earnings, less each of the items in its name as well as impairment losses, working capital and capital expenditures. While EBITDA may vary between companies and between industries, the Company believes that this measure will be useful to external users in assessing operating performance.

Working capital – The Company has disclosed its initial working capital needs which include accounts receivables and inventories, but not deducted accounts payable, income taxes payable and other accrued liabilities which would generally be included in the definition of working capital. While working capital may vary between companies and between industries, the Company believes that this measure will be useful to external users in assessing the initial cash requirements needed to fund the Project.

CAUTIONARY STATEMENT

The Feasibility Study (also referred to as “FS” throughout) referred to in this announcement is intended to be used for the process of financing the construction of the Chvaletice Manganese Project by outlining the technical, commercial and profit potential aspects of the Project. The technical and economic study has a number of sections of that have accuracy ranges from ± 5% to ± 20% depending on the materiality of the section. The overall accuracy of the FS is judged to be in the order of -15% to +20%. The directors of the Company consider this to be a fair and balanced summary of the study undertaken. However, given the uncertainties involved in any study of this type, and the assumptions made, investors should not make any investment decisions based solely on the results of the FS and/or the summary contained herein.

The FS is based on the material assumptions outlined in this news release which include assumptions about the availability of funding. While EMN considers all of the material assumptions to be based on reasonable grounds, there is no certainty that they will prove to be correct or that the range of outcomes indicated by the FS can be achieved.

While the Company believes it has reasonable grounds to assume it will be able to fund the development of the Project, as described herein under “Project Financing,” investors should note that there is no certainty that it will be able to raise that amount of funding when needed. It is also likely that such funding may only be available on terms that may be dilutive to or otherwise affect the fundamental value of EMN’s existing shares.

ABOUT EURO MANGANESE INC.

Euro Manganese Inc. is a battery materials company focused on becoming a leading, competitive, and environmentally superior producer of high-purity manganese for the electric vehicle (EV) industry and other high-technology applications. The Company is advancing development of the Chvaletice Manganese Project in the Czech Republic, which is a unique waste-to-value recycling and remediation opportunity involving reprocessing old tailings from a decommissioned mine. The Chvaletice Project is the only sizable resource of manganese in the European Union, strategically positioning the Company to provide battery supply chains with critical raw materials to support the global shift to a circular, low-carbon economy.

Authorized for release by the CEO of Euro Manganese Inc.

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) or the ASX accepts responsibility for the adequacy or accuracy of this release.

INQUIRIES

Dr. Matthew James

President & CEO

+44 (0)747 229 6688

Louise Burgess

Senior Director Investor Relations & Communications

+1 (604) 312-7546

lburgess@mn25.ca

Company Address: #709 -700 West Pender St., Vancouver, British Columbia, Canada, V6C 1G8

Website:www.mn25.ca

FORWARD LOOKING STATEMENTS

Certain statements in this news release constitute “forward-looking statements” or “forward-looking information” within the meaning of applicable securities laws. Such statements and information involve known and unknown risks, uncertainties and other factors that may cause the actual results, performance or achievements of the Company, its projects, or industry results, to be materially different from any future results, performance or achievements expressed or implied by such forward-looking statements or information. Such statements can be identified by the use of words such as “may”, “would”, “could”, “will”, “intend”, “expect”, “believe”, “plan”, “anticipate”, “estimate”, “scheduled”, “forecast”, “predict” and other similar terminology, or state that certain actions, events or results “may”, “could”, “would”, “might” or “will” be taken, occur or be achieved.

Results of the Feasibility Study constitutes forward-looking information or statements, including but not limited to estimates of internal rates of return (including any pre-tax and after-tax internal rates of return), payback periods, net present values, future production, assumed prices for HPMSM and HPEMM, ability of the Company to achieve a pricing premium for its products, proposed extraction plans and methods, operating life estimates, cash flow forecasts, metal recoveries and estimates of capital and operating costs. Such forward-looking information or statements also include, but are not limited to, statements regarding the Company’s intentions regarding the Project in the Czech Republic, the development of the Project, the ability to source green power and other requirements for the Project, the completion and submission of an environmental and social impact assessment, statements regarding the ability of the Company to obtain remaining surface rights, the net positive benefits of the Project, the growth and development of the high purity manganese products market, the desirability of the Company’s products, the growth of the EV industry, the use of manganese in batteries, the manganese project supply line, support from European financial institutions, and the Company’s ability to obtain financing for the Project.

Readers are cautioned not to place undue reliance on forward-looking information or statements. Forward-looking information and statements involve significant risks and uncertainties, should not be read as guarantees of future performance or results, and will not necessarily be accurate indicators of whether or not such results will be achieved. Forward-looking statements are subject to a number of risks and uncertainties that may cause the actual results of the Company to differ materially from those discussed in the forward-looking statements and, even if such actual results are realized or substantially realized, there can be no assurance that they will have the expected consequences to, or effects on, the Company.

Factors that could cause actual results or events to differ materially from current expectations include, among other things: the ability to develop adequate processing capacity; the availability of equipment, facilities, and suppliers necessary to complete development; the cost of consumables and extraction and processing equipment; risks and uncertainties related to the ability to obtain, amend, or maintain necessary licenses, or permits, risks related to acquisition of surface rights; risks and uncertainties related to expected production rates; timing and amount of production and total costs of production; the potential for unknown or unexpected events to cause contractual conditions to not be satisfied; the failure of parties to contracts with the Company to perform as agreed; risks and uncertainties related to the accuracy of mineral resource and reserve estimates, the price of HPEMM and HPMSM, power supply sources and price, reagent supply resources and prices, future cash flow, total costs of production, and diminishing quantities or grades of mineral resources and reserves; changes in Project parameters as plans continue to be refined; risks related to global epidemics or pandemics and other health crises, including the impact of the novel coronavirus (COVID-19); availability and productivity of skilled labour; risks and uncertainties related to interruptions in production; unforeseen technological and engineering problems; the adequacy of infrastructure; risks related to Project working conditions, accidents or labour disputes; social unrest or war; the possibility that future results will not be consistent with the Company's expectations; risks relating to variations in the mineral content and grade within resources from that predicted; variations in rates of recovery and extraction; developments in EV battery markets and chemistries; and risks related to fluctuations in currency exchange rates, changes in laws or regulations; and regulation by various governmental agencies. For a further discussion of risks relevant to The Company, see "Risk Factors" in the Company's annual information form for the year ended September 30, 2021, available on the Company's SEDAR profile at www.sedar.com.

All forward-looking statements are made based on the Company's current beliefs as well as various assumptions made by the Company and information currently available to the Company. Generally, these assumptions include, among others: the presence of and continuity of manganese at the Project at estimated grades; the ability of the Company to obtain all necessary land access rights; the availability of personnel, machinery, and equipment at estimated prices and within estimated delivery times; currency exchange rates; manganese sales prices and exchange rates assumed; growth in the manganese market; appropriate discount rates applied to the cash flows in economic analyses; tax rates and royalty rates applicable to the proposed operations; the availability of acceptable Project financing; anticipated extraction losses and dilution; success in realizing proposed operations; and anticipated timelines for community consultations and the impact of those consultations on the regulatory approval process.

Although the forward-looking statements contained in this news release are based upon what management of the Company believes are reasonable assumptions, the Company cannot assure investors that actual results will be consistent with these forward-looking statements. These forward-looking statements are made as of the date of this news release and are expressly qualified in their entirety by this cautionary statement. Subject to applicable securities laws, the Company does not assume any obligation to update or revise the forward-looking statements contained herein to reflect events or circumstances occurring after the date of this news release.

APPENDIX 1

JORC CODE 2012 Edition Table 1 Disclosure

SECTION 1 Sampling Techniques and Data

| Criteria |

Explanation |

| Sampling Techniques |

- The 2018 sampling program is summarized as:

- Sonic rig advanced at 2 m intervals using 100mm core tube, approx. 14 kg wet weight per sample.

- 730 core samples (2 m) of tailings material were recovered for analysis.

- Samples extracted from core tube at 1 m subsamples (approx. 7 kg wet weight) for logging and physical measurements.

- A quarter split (approx. 3.5 kg wet weight) was extracted from the 1 m subsamples, recombined with the corresponding 1 m quarter split subsample, bagged and shipped to SGS for particle size analysis, lithogeochemistry, metals analysis and bulk density testing (approx. 7 kg for 2 m representative sample.

- Remaining ¾ sample was split for additional test work in Czech Republic, and for metallurgical test work in China.

- All samples were clearly labelled and stored in vacuum-packed and sealed plastic bags to preserve original moisture content and prevent sample deterioration. Geochemical samples were contained in plastic buckets, inventoried and stored in a locked facility in Prelouc, Czech Republic, prior to being shipped to SGS Bor.

|

| Drilling Techniques |

- The 2018 program completed drilling of 1,509.5 metres in 80 holes.

- The program included completion of 35 vertical and 19 inclined 100 mm diameter Sonic holes, totaling 1,409.5 m, and an additional 26 mobile percussion drill holes, totaling 100 m, were completed around the perimeter embankments of the tailings piles in areas which were not previously accessed for sampling.

- Sonic holes were placed as infill holes with approximately 75 metre spacing between 2017 holes and as inclined directed underneath the outer perimeter embankment, using 100 mm diameter size rods and sonic core barrel advance provided by Eijkelkamp SonicSampDrill B.V. and crews from Giesbeek, the Netherlands.

|

| Drill Sample Recovery |

- Recoveries estimated by field crew and recorded on geological logs.

- No casing was installed and drill rods were pulled for each core run.

|

| Logging |

- Logging was conducted in the field at drill side by GET sro, on hard copy paper and transcribed into digital drillhole database.

- Records include lithological description, wet mass, estimated recovery, and volume.

|

| Subsampling Techniques and Sample Preparation |

- Sampling excludes overlying topsoil, and underlying native soil substrate.

- Assay samples received at SGS Bor were weighed (wet) and homogenized by hand using the “Japanese slab cake method” of kneading and rolling the sample.

- A 500 g subsample sent to laser diffraction particle size analysis.

- The remaining sample was dried (105 degrees C) and homogenized.

- 1 kg was extracted for pulverization to 95% passing 75µm mesh.

- First stage of analysis was conducted SGS in Bor, Serbia, which included partial digestion using aqua regia with ICP/MS or AAS, and near total digestion using four acids (nitric, perchloric, hydrofluoric and hydrochloric) with ICP/MS or AAS from 0.5g aliquots.

- The second stage of analysis was conducted at SGS in Lakefield, Ontario, Canada, which included using lithium borate fusion and x-ray fluorescence (XRF) for major concentration of major cation oxide, concentration of in organic sulphur and carbon using LECO furnace, measurement of specific gravity by pycnometer, and for particle size analysis by LD-PSA.

- Total of 888 samples were analyzed at SGS laboratories.

|

| Quality of Assay Data and Laboratory Tests |

- Quality control (QC) protocol included insertion of field duplicates (5%), blank (4%) and certified reference samples (5%) in all drill holes, collection of sample preparation duplicate (5%) and pulp duplicates (2%).

- Three holes were drilled in 2018 to twin holes completed in 2017.

- A database was compiled, and various checks and measures were performed by Tetra Tech. No significant quality assurance (QA) concerns were identified by the Competent Person.

|

| Verification of Sampling and Assaying |

- Independent analyses were conducted by an external umpire laboratory; Activation Laboratories, located in Ancaster, Ontario, Canada. The lab received 96 representative samples (approximately 1 in 10).

- Independent CP sampling was conducted.

|

| Location of Data Points |

- Property topography was provided by GET sro in Czech projection S-JTSK using the Bpv datum.

- Surveying of drill hole collars was completed on-site by GET using a Trimble model R4 GNSS global positioning system (GPS) receiver equipment.

|

| Data Spacing and Distribution |

- Infill Sonic holes (35) were spaced at approximately 100 m, giving approximately 75m overall average spacing including the 2017 drill holes.

- Perimeter Sonic holes (19) were inclined at 45 degrees and spaced at two holes per side of the tailings cells.

- Perimeter percussion holes (26) were drilled vertically and spaced at approximately two to three holes per side of the tailings cells.

- Downhole sampling continuous at 2 m intervals.

|

| Orientation of Data in Relation to Geological Structure |

- Drillholes were drilled both vertically and inclined through heterogeneous tailings mass.

|

| Sample Security |

- Samples stored at a field warehouse managed by Geomin in Jihlava prior to shipping to laboratory for analyses.

|

| Audits or Reviews |

- Independent site visit, sampling and data review completed by Tetra Tech Competent Person, James Barr, P.Geo., during the delineation drilling campaign on July 30-31st, 2018.

|

SECTION 2 Reporting of Exploration Results

| Criteria |

Explanation |

| Mineral Tenement and Land Tenure Status |

- Mangan is a private company established in the Czech Republic in 1997, is 100% owned by Euro Manganese Inc., and holds 100% ownership of exploration licence number 631/550/14-Hd (which was valid until September 30, 2019, but on December 4, 2018 was renewed and extended to May 31, 2026) and exploration licence number MZP/2018/550/386-Hd (valid until May 31, 2026).

- Exploration licence number 631/550/14-Hd is registered to include mineral rights on a total area of 0.98 km² (98 ha) which cover the Chvaletice Manganese Project deposits, of which 0.82 km² is located within the Municipality of Trnavka, and 0.16 km² is located within the Municipality of Chvaletice.

- Exploration licence MZP/2018/550/386-Hd allows the company to drill on the perimeter of the tailings piles.

- On April 28, 2018, Mangan was issued a Preliminary Mining Permit by the Ministry of Environment, Licence No. MZP/2018/550/387-HD which covers the areas included in the Exploration Licences and secures Mangan’s rights for the entire deposit area and is a prerequisite for the application for the establishment of the Mining Lease District.

- On July 20, 2021, Mangan was issued a new Preliminary Mining Permit, Licence No. MZP/2021/550/92-Hd, valid until May 31, 2026.

- At present, Mangan does not hold surface rights to the Chvaletice Manganese Project area, which are considered as those lands of original ground elevation surrounding and immediately underlying the protected area that contains tailings Cells 1, 2, and 3. The area of interest for the Chvaletice Manganese Project overlies and adjoins 18 privately owned land parcels.

- An aggregated land package covering 26.64 ha has been purchased, or has option agreement to be purchased, by Mangan. The parcel of land is proposed for development and construction of a high-purity manganese processing facility and related infrastructure.

|

| Exploration Done by Other Parties |

- Hand auger sampling in 2014, four holes ranging from 2 to 2.5 m depth.

- Testpit sampling in 2015, seven testpits ranging between 1.8 to 3.8 m depth.

|

| Geology |

- The mineralization found in tailings at the Chvaletice Manganese Project deposited by manmade processes following grinding and flotation processes of black pyritic shale and is therefore not characteristic of a traditional bedrock hosted manganese deposit.

- The material can be physically characterized as a compacted soil, with varying degrees of particle sizes from clay to coarse sand.

- Mineralogy has been quantified by limited x-ray diffraction (XRD) analyses, with resulting manganese bearing mineral phases as rhodochrosite (and other Mn-bearing carbonates), spessartine (and other Mn-silicates); quartz was the main gangue mineral, and pyrite was the main sulphide mineral.

|

| Drill Hole Information |

- Drillholes were collared on the surface of the tailings deposits and drilled vertically downwards to completion in the underlying native soil substrate, approximate average depth in Cell 1 = 26 metres, Cell 2 = 27 metres and Cell 3 = 11 metres.

|

| Data Aggregation Methods |

- Raw drillhole samples were composited to 2 metre intervals for use in mineral resource estimation.

|

| Relationship Between Mineralization Widths and Intercept Points |

- Downhole width is equivalent to true width.

|

| Diagrams |

- Diagrams, maps and cross-sections are included in the press release for reference.

|

| Balanced Reporting |

- All of the tailing material which has been assayed has reported elevated concentration of manganese

- 2018 Sample assay grades range from 0.19% to 11.69% total Manganese (by XRF analysis), with mean value of 7.29%.

|

| Other Substantive Exploration Data |