- About 830 kg of input ilmenite rich material produced approximately 88 kg of titanium dioxide (TiO2) with an average grade of 99.8%

- Based on purity, applications include use as a precursor for pigments, filler for pulp and paper, ceramics, and consumer products including sunscreen and cosmetics

Temas Resources Corp.(“Temas” or the “Company”)[CSE: TMAS] is pleased to report positive pilot plant results for the recovery of high purity titanium dioxide from ilmenite-rich anorthosite ore from its La Blache titanium (Ti) - iron (Fe) – vanadium (V) – chromium (Cr) property in Quebec.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20220728005284/en/

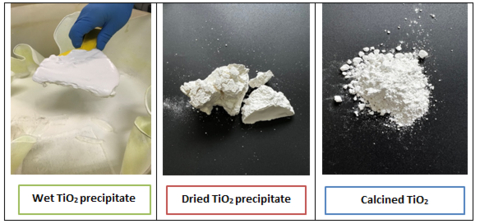

Photo 1. TiO2 products produced at different process steps (Graphic: Business Wire)

A two-phase test program was implemented to process ~830 kg of La Blache ilmenite rich anorthosite to recover a high purity TiO2 product. The La Blache property, situated on Quebec’s North Shore approximately 100 km from the city of Baie-Comeau, consists of ilmenite rich material comprising ~41% Fe, ~10.6% Ti and ~0.18% V. Temas engaged Process Research ORTECH Inc. (PRO) to apply the 50% Temas-owned ORF patented chloride process for the treatment of the ilmenite ore to recover the titanium dioxide product. The pilot plant is located in Mississauga, Ontario, Canada.

Michael Dehn, CEO of Temas Resources states, “We are satisfied that the pilot plant results have confirmed the ability to produce a high purity TiO2 product from ilmenite rich anorthosites. With the 88 kg produced from the program, we are currently engaging with potential customers, and providing material for their own quality testing. Results from this pilot plant program will be used to develop our Preliminary Economic Assessment (“PEA”) on the La Blache project.”

Phase 1 of the test program involved a bench-scale and mini-pilot test program to evaluate and optimize the Ti and Fe recovery from the ilmenite rich anorthosite. A two-stage mixed-chloride leaching process, which attained an overall Ti recovery of 80.6%, was undertaken. Preliminary mini-pilot solvent extraction circuits were also run to establish steady state operation conditions prior to the large pilot operation in Phase 2 of the program. It was found that selectivity was maintained in both the Fe and Ti solvent extraction (“SX”) circuits, with high purity Ti pregnant strip solution produced.

The Ti-rich pregnant strip liquor underwent thermal precipitation and a total of ~88 kg of TiO2 product was recovered with an average of 99.8% purity in the two-phase test programs. The overall impurities present in the final product ranged between 0.08% and 0.26%. Based on the quality of the TiO2 product, end uses include applications as a precursor for pigments, filler for pulp and paper, ceramics and consumer products (i.e., cosmetics and sunscreen).

The chemical analysis of the composite head sample is provided below in Table 1. There was 41.06% Fe and 10.61% Ti in the head sample.

Representative samples of the ilmenite rich anorthosite were pulverized and analyzed by X-ray diffraction (XRD) at an accredited laboratory of Activation Laboratories Ltd. in Ancaster, ON. Table 2 highlights the mineral abundances (wt%) in the ore. It is determined that the majority phases are magnetite and ilmenite.

The overall process flowsheet for processing of ilmenite concentrate derived from La Blache anorthosite ore to produce market grade TiO2 is shown in Figure 1.

This process flowsheet can be divided into the following steps:

Mixed Chloride Leaching (2 Stages)

Atmospheric pressure leaching was conducted on a -65 mesh feed material with a mixed chloride lixiviant at 70°C. Two-stage leaching was performed to achieve a target overall Ti recovery of greater than 80%. After the first stage of leaching, the slurry undergoes solid-liquid separation with the addition of a flocculant to improve the rate of filtration. The resulting solid residue was used in the second stage of leaching and the pregnant leach solutions (PLS) obtained from both stages were combined prior to use in the subsequent process steps. An overview of the two-stage leaching process is shown in Figure 2.

Oxidation

The pregnant leach solution (PLS) obtained from the two-stage leaching underwent oxidation for the conversion of ferrous ion (Fe2+) to ferric ion (Fe3+). The PLS was pumped into columns in which oxygen gas (O2) was sparged, as show in Figure 3. Following oxidation, solvent extraction stages were conducted to separate iron and titanium selectively.

Iron (Fe) Solvent Extraction

The oxidized PLS was contacted with an organic phase to selectively load iron into the organic phase. Iron loaded organic phase was scrubbed with a high concentration iron solution and then stripped by contacting with a barren strip solution to generate iron-rich pregnant strip liquor. Figure 4 demonstrates the Fe solvent extraction (SX) circuit and Table 3 presents the results, and Photo 2 is of the Fe circuit.

Titanium (Ti) Solvent Extraction

The raffinate obtained from iron solvent extraction was contacted with an organic phase to selectively load titanium into the organic phase (Fe Raffinate Solution in Figure 4). Titanium loaded organic phase was scrubbed with a high concentration titanium solution and then stripped by contacting with a barren strip solution to produce titanium-rich pregnant strip liquor. Figure 5 shows the Ti SX circuit and Table 4 presents the results, with Photo 3 being of the Ti circuit.

Titanium Dioxide Precipitation

Titanium dioxide is precipitated from titanium-rich pregnant strip liquor by thermal precipitation at 95°C. There is a pre-treatment step prior to thermal precipitation during which any residual organic is removed from the Ti pregnant strip liquor by activated carbon. After precipitation, there are stages of HCl wash and water wash to remove any further impurities. During the water wash, the pH of the slurry is increased using ammonium hydroxide (NH4OH), increasing the filtration rate. The final step is calcination of the solid product at 800°C for 2 hours to produce TiO2.

Titanium present in the pregnant strip liquor obtained from the TiSX circuit underwent thermal precipitation to produce the desired product of TiO2. The process is represented by the following reaction:

TiOCl2 (aq) + 2H2O (l) = TiO(OH)2 (s) + 2 HCl (aq)

After filtering and washing, the product was oven dried and then calcined at 800°C in order to transform the TiO(OH)2 into TiO2, as shown by the following reaction:

TiO(OH)2 (s) = TiO2 (s) + H2O (l)

The overall TiO2 precipitation process is shown in Figure 6 with the stages of precipitation in photo 1 and final product in photo 4.

Additional Product Recovery: Iron oxide

Although the following was not part of the pilot plant test work, Fe can be recovered as an iron oxide (Fe2O3 - hematite) from the pregnant strip solution obtained from FeSX. Ferric and ferrous chlorides react with water at high temperature in a pyrohydrolysis unit such as a spray roaster to produce HCl gas and Fe2O3. The iron oxide is collected as the final iron product from the process, while the HCl gas is recovered by absorbing into process water to produce a 5.8N HCl solution, which recycles to the leaching stages. Pyrohydrolysis is a well understood, fully commercialized operation. Pyrohydrolysis units are available from commercial vendors and can be customized to fit the iron pregnant strip quality and volumetric flow rate. The high purity iron oxide can then be used as precursor for iron making or as a pigment. Figure 7 shows the pyrohydrolysis process.

The Phase 1 components of bench-scale test work and subsequent mini-pilot plant operation were successfully implemented with steady state operation achieved in both the Fe and Ti SX circuits. The overall average leach recoveries after two-stage leaching was 80.63% Ti, 94.16% Fe and 99.33% V. Flocculation was performed after the first stage of leaching to improve the solid-liquid separation. A total of 12 first stage leaches (600 litres) and 4 second stage leaches (80 litres) were conducted for this phase, resulting in ~680 litres of PLS solution for solvent extraction circuits. The mini-pilot FeSX circuit was operated for 162 hours, which produced an average of ~64 ppm Fe in the raffinate solution and an average of ~75 g/l Fe in the iron rich pregnant strip solution. Similarly, the mini-pilot TiSX circuit was operated for 105 hours, which produced an average composition of ~33 g/l Ti in the strip solution that was used for initial TiO2 precipitation tests.

Conclusions

Pilot plant operation was successfully conducted for the recovery of TiO2 from the La Blache ilmenite rich anorthosite. The major phases in the ore were magnetite and ilmenite, and comprised of ~41% Fe and ~10.6% Ti. The ore also consisted of ~0.18% V, ~0.20% Mn and ~0.11% Cr, which offered challenges in producing high purity TiO2 meeting market specifications, as well as opportunities for recovery of additional commercial products. After extensive test work, a flowsheet was developed using ORF’s chloride process. The flowsheet consists of crushing, grinding, two-stage leaching in mixed chloride lixiviant, solvent extraction, followed by precipitation and calcination to obtain a high purity TiO2 product. The two-phase test program processed ~830 kg of ilmenite ore with ~6815 litres of PLS produced for the solvent extraction circuits. In Phase 1, the Fe and Ti circuits were operated for ~162 hours and ~105 hours, respectively. Whereas, in the larger pilot operation of Phase 2, the Fe circuit was run for ~654 hours (completing 120 organic turnovers) and the Ti circuit was run for ~581 hours (completing 30 organic turnovers). The Ti-rich pregnant strip liquor underwent thermal precipitation followed bywashing stages to remove the impurities, and the final step of calcination at 800°C. A total quantity of 88 kg of TiO2 was produced with an average of + 99.8% purity in the two-phase test program.

About Titanium Dioxide

Titanium dioxide was first manufactured a century ago. Today the TiO2 market is over $17 Billion USD. Its chemical inertness allows for it to have a wide range of applications in photocatalysis, in the pharmaceutical industry, and in food processing sectors. Its practical uses stem from its dual feature to act as both a semiconductor and light scatterer.

Titanium dioxide is a nontoxic antimicrobial with potential bactericidal and fungicidal applications in food contact and packaging surfaces.

Titanium dioxide can be used as a permanent pigment used in paints, plastics, rubber, ceramics, cosmetics, food and in toothpaste. Titanium dioxide is the best performing white pigment available because of its high optical index of refraction. It provides maximum whiteness and opacity in the materials it is used in. It gives paint high hiding power, meaning the ability to mask or hide a substrate. It does this more effectively than any other commercially available white pigment. Today, titanium dioxide pigment is by far the most important material used by the paints and plastics industries for whiteness and opacity.

QUALIFIED PERSONS

Rory Kutluoglu, P.Geo and Robert W. Schafer, P.Geo, are Qualified Persons as defined by NI 43-101 and have reviewed and approved the technical information contained within this press release.

On behalf of the Board of Directors,

Michael Dehn, President & CEO

About Temas Resources

Temas Resources Corp. (CSE: TMAS) (OTCQB: TMASF) is focused on the advancement of mineral independence and processes by which mineral products (nickel, iron, copper, gold, ilmenite and other sulphide and oxide mineral ores and concentrates) are processed and recovered using sustainable hydrometallurgical technologies. The Company invests in and works to apply its green technologies across its mining portfolio to reduce the environmental impact and carbon footprint of metal extraction through advanced processing and patented leaching technologies. The Company is advancing Iron-Titanium-Vanadium projects in Quebec and has recently published results from a preliminary economic assessment on the Piskanja Boron Project in Serbia.

All public filings for the Company can be found on the SEDAR website www.sedar.com. For more information about the Company, please visit www.temasresources.com.

Cautionary Note Regarding Forward-Looking Statements

This news release contains forward-looking statements and forward-looking information (collectively, “forward-looking statements”) within the meaning of applicable Canadian and U.S. securities legislation. All statements, other than statements of historical fact, included herein including, without limitation, the results of the PEA, including the projected Capex, the estimated after-tax NPV and IRR, the estimated LOM and estimated concentrate grades, the potential production from and viability of Piskanja, the risks and opportunities outlined in the PEA, the potential tonnage, grades and content of deposits, the extent of mineral resource estimates, anticipated exploration program results from exploration activities, the discovery and delineation of mineral deposits/resources/reserves and the anticipated business plans and timing of future activities of the Company are forward-looking statements. Although the Company believes that such statements are reasonable, it can give no assurance that such expectations will prove to be correct. Forward-looking statements are typically identified by words such as: “believes”, “expects”, “anticipates”, “intends”, “estimates”, “plans”, “may”, “should”, “would”, “will”, “potential”, “scheduled” or variations of such words and phrases and similar expressions, which, by their nature, refer to future events or results that may, could, would, might or will occur or be taken or achieved. In making the forward-looking statements in this news release, the Company has applied several material assumptions, including without limitation, that the Company will receive all necessary approvals required to develop Piskanja as outlined in the PEA, that the assumptions in the PEA are reasonably accurate, market fundamentals will result in sustained boron demand and prices, the receipt of any necessary permits, licenses and regulatory approvals in connection with the future development of Piskanja in a timely manner, the availability of financing on suitable terms for the development, construction and continued operation of the Company’s projects and its ability to comply with environmental, health and safety laws.

Forward-looking statements involve known and unknown risks, uncertainties and other factors which may cause the actual results, performance or achievements of the Company to differ materially from any future results, performance or achievements expressed or implied by the forward-looking information. Such risks and other factors include, among others, requirements for additional capital, operating and technical difficulties in connection with mineral exploration and development activities, actual results of exploration activities, including on the Piskanja project, the estimation or realization of mineral reserves and mineral resources, and there is no guarantee that such interests, will be certain, the timing and amount of estimated future production, the costs of production, capital expenditures, the costs and timing of the development of new deposits, requirements for additional capital, future prices of boron, changes in general economic conditions, changes in the financial markets and in the demand and market price for commodities, lack of investor interest in future financings, accidents, labour disputes and other risks of the mining industry, delays in obtaining governmental approvals (including of the TSX Venture Exchange), permits or financing or in the completion of development or construction activities, risks relating to epidemics or pandemics such as COVID–19, including the impact of COVID–19 on the Company’s business, financial condition and results of operations, changes in laws, regulations and policies affecting mining operations, title disputes, the inability of the Company to obtain any necessary permits, consents, approvals or authorizations, the timing and possible outcome of any pending litigation, environmental issues and liabilities, and risks related to joint venture operations, and other risks and uncertainties disclosed in the company’s continuous disclosure documents. All of the Company’s Canadian public disclosure filings may be accessed via www.sedar.com and readers are urged to review these materials.

Readers are cautioned not to place undue reliance on forward-looking statements. The Company does not undertake any obligation to update any of the forward-looking statements in this news release or incorporated by reference herein, except as otherwise required by law.

Cautionary Note to United States Investors

Temas Resource Corp. prepares its disclosure in accordance with the requirements of securities laws in effect in Canada, which differ from the requirements of U.S. securities laws. Terms relating to mineral resources in this news release are defined in accordance with NI 43-101 under the guidelines set out in CIM Definition Standards on Mineral Resources and Mineral Reserves, adopted by the Canadian Institute of Mining, Metallurgy and Petroleum Council on May 19, 2014, as amended (“CIM Standards”). The U.S. Securities and Exchange Commission (the “SEC”) has adopted amendments effective February 25, 2019 (the “SEC Modernization Rules”) to its disclosure rules to modernize the mineral property disclosure requirements for issuers whose securities are registered with the SEC under the U.S. Securities Exchange Act of 1934.

As a result of the adoption of the SEC Modernization Rules, the SEC will now recognize estimates of “measured mineral resources”, “indicated mineral resources” and “inferred mineral resources”, which are defined in substantially similar terms to the corresponding CIM Standards. In addition, the SEC has amended its definitions of “proven mineral reserves” and “probable mineral reserves” to be substantially similar to the corresponding CIM Standards.

U.S. investors are cautioned that while the foregoing terms are “substantially similar” to corresponding definitions under the CIM Standards, there are differences in the definitions under the SEC Modernization Rules and the CIM Standards. Accordingly, there is no assurance any mineral resources that Temas may report as “measured mineral resources”, “indicated mineral resources” and “inferred mineral resources” under NI 43-101 would be the same had Temas Resource Corp. prepared the resource estimates under the standards adopted under the SEC Modernization Rules.

In accordance with Canadian securities laws, estimates of “inferred mineral resources” cannot form the basis of feasibility or other economic studies, except in limited circumstances where permitted under NI 43-101.

NEITHER THE CSE NOR ITS REGULATION SERVICES PROVIDER (AS THAT TERM IS DEFINED IN THE POLICIES OF THE TSX VENTURE EXCHANGE) ACCEPTS RESPONSIBILITY FOR THE ADEQUACY OR ACCURACY OF THIS RELEASE.

View source version on businesswire.com: https://www.businesswire.com/news/home/20220728005284/en/