(TheNewswire)

Vancouver,BritishColumbia – TheNewswire – September 8, 2022 - GoldBasinResourcesCorporation(the"Company"or"Gold Basin") – (TSXV:GXX), (OTC:GXXFF) is pleased to report on its column leach Metallurgical Testwork conducted by Kappes Cassiday & Associates (KCA) in Reno, Nevada between December 2021 and May 2022 on diamond core samples from the Cyclopic area of its 100%-owned Gold Basin project in Mohave County, Northern Arizona, USA.

SUMMARY

-

Gold extractions up to 80% (after 67-72 days of leach) on Cyclopic diamond core composite samples

-

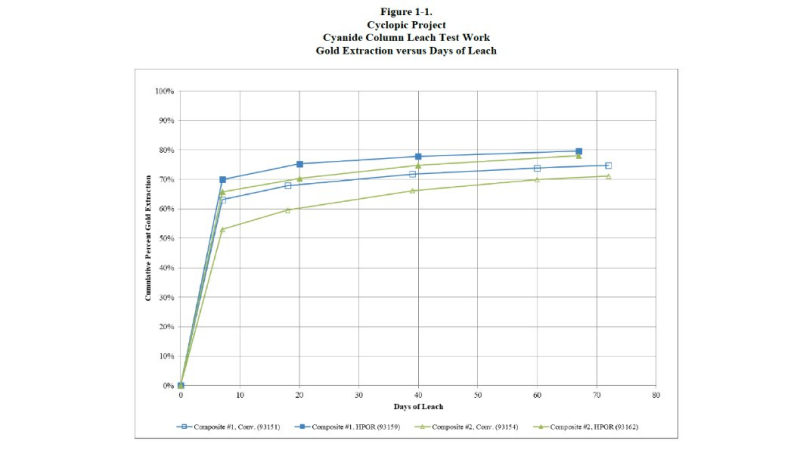

Gold extractions between 50 and 70% after 7 days in leach

-

Agglomeration and compaction tests showed all agglomerated samples passed percolation tests up to 100 metres dump height (KCA standard height recommendation is 40 metres)

-

Gold Basin mineralisation extremely low in preg-robbing soluates and less than 0.61% total carbon in the material

-

All results show low reagent consumption in leach

All results indicate Gold Basin mineralisation is a rapid leaching material with low preg-robbing characteristics that when agglomerated passes industry criteria for flow rates for dump heights up to 100 metres.

CEO Mike Povey commented, “We are pleased with this initial set of metallurgical testwork results that demonstrate strong recoveries that are indicative of a broad range of heap-leach projects in the SW USA. In consultation with KCA, we expect future optimisation testwork to begin evaluating coarser crush opportunities as we continue to focus on extending the mineralisation and thus increase ore samples for further composites. The results are an excellent start and confirm there are no metallurgical barriers to a heap-leach gold extraction operation at Gold Basin.”

COLUMN LEACH TESTWORK RESULTS

Further to the Company’s positive initial Bottle Roll leach testwork completed in late 2021 (news release dated February 03, 2022) further metallurgical studies have been undertaken in order to determine additional parameters on the heap leach suitability of the Gold Basin mineralisation. As preparation for these studies the Company drilled four (4) PQ core diamond drillholes at 200 metres intervals along strike at the Cyclopic deposit during the 2021 resource drilling program. This drillhole interval sequence and depth of hole was determined to provide a sufficiently representative mineralised samples for the planned testwork.

The core samples were delivered to KCA’s laboratory facilities in Reno, Nevada on the 6th December 2021 and the metallurgical program of work was undertaken between December 2021 and May 2022 included column leach and agglomeration / compaction testwork as well as some additional bottle roll tests.

In order to evaluate the relative effects on gold extraction both conventional crushing and High Pressure grinding roll (HPGR) crushing methodology was used to prepare the diamond core material for the column leach and agglomeration tests.

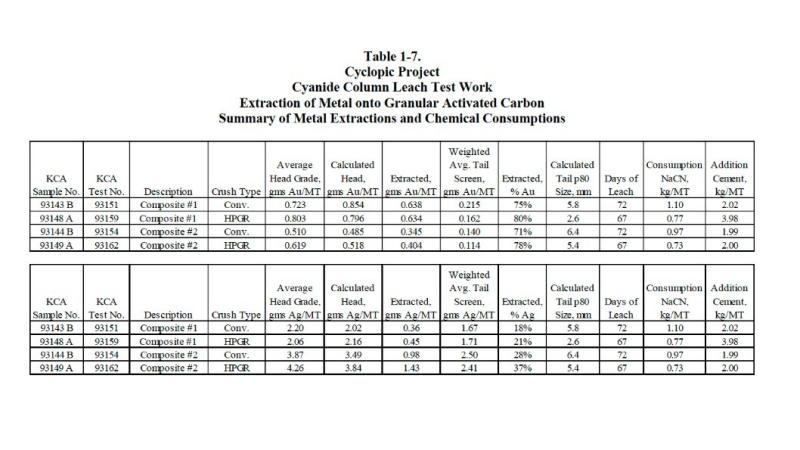

Under reagent in the column leach all samples showed a rapid extraction response to the reagent solution with gold recoveries between 52% and 70% being achieved after only 7 days of leaching. Each sample was progressed to where the leaching had effectively plataued and provided:

-

Column leach gold extractions of 75% and 71% on conventional crushed composite samples after 72 days of leach period:

-

HPGR crushing resulted in an increased gold extractions of 80% and 78% after 67 days of leach

Table 1 and Figure 1 below show the summary results of the gold recoveries from the column tests.

Table 1: Cyclopic Project - Column Leach Test Work

Summary Gold Extractions and Chemical Consumption.

Click Image To View Full Size

Figure 1: Cyclopic Gold Extraction v Days of Leach

Click Image To View Full Size

Agglomeration and Compaction Test Work

Preliminary agglomeration and compacted permeability test work was conducted on portions of the conventionally crushed material and HPGR crushed material from each composite sample.

The purpose of the percolation tests was to examine the permeability of the material under

various cement agglomeration levels (0, 2, 4 and 8 kilograms per metric tonne of Portland

Type II cement.

All samples tested passed the KCA criteria for flow rate with the exception of HPGR crushed Composite 1 (KCA Sample No. 93148 A) that had no cement addition.

The purpose of the compacted permeability test work was to examine the permeability of the crushed material, agglomerated at various cement levels, under compaction loading equivalent to heap heights of 20 and 100 metres of overall heap height.

Both the conventional crushed material (agglomerated with 2 and 5 kg/MT cement) and the HPGR crushed product (agglomerated with 4 and 8 kg/MT cement) for Composite #1, failed at an equivalent heap height of 100 meters due to low solution flow rate and/or excessive slump. The HPGR crushed product (agglomerated with 2 kg/MT cement) for Composite #2, failed at an equivalent heap height of 100 metres due to low solution flow rate.

KCA’s general recommendations for heap leach dump heights are a maximum of 40m

Solubility Analyses and Preg-Robbing Tests

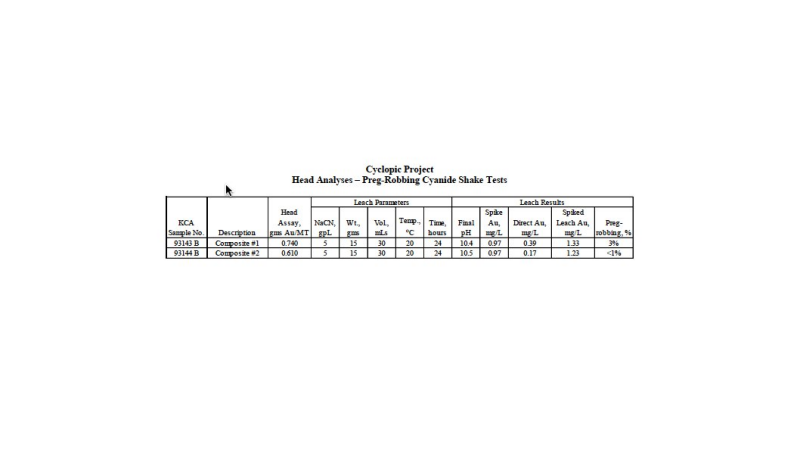

Shake tests were conducted on portions of the pulverized head material to provide preliminary indications of soluble metal extractions as part of the testwork process.

In order to investigate the preg-robbing characteristics of the Cyclopic material (often a result of carbonaceous inclusions in particular) additional shake testing was conducted. For these preg-robbing tests, pulverized portions of head material were leached by the same method as the initial shake tests with the addition of a known quantity (spike) of gold in solution. Preg-robbing tendency was then determined by comparing the spiked shake test extraction and the original shake test extraction with the gold spike (original extraction + gold spike).

Preg-rob% = 100% – ((Spiked Shake Ext.)/(Shake Ext. + Spike)×100%)

If the spiked shake test extraction was lower than the shake test + spike more than 10%, the shake was considered preg-robbing. Differences less than 10% were Differences less than 10% were attributed to variations in the material.

The samples tested showed less than 3% preg-robbing and are summarised in Table 2.

Table 2: Cyclopic Project

Head Analyses Preg Robbing Shake Tests

Click Image To View Full Size

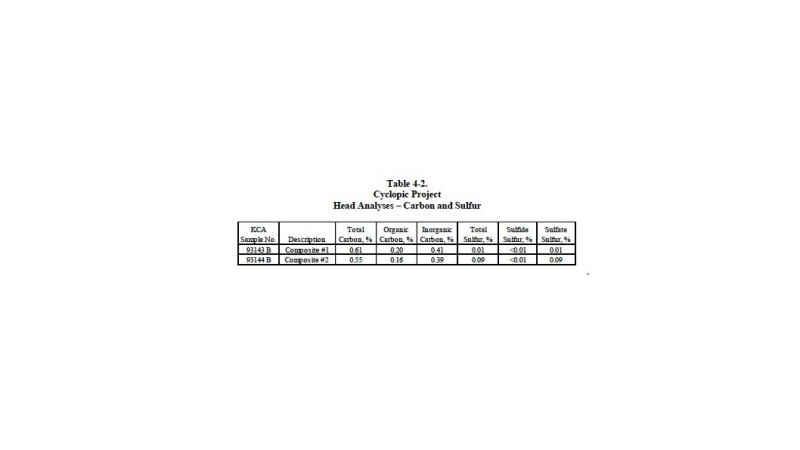

In addition to preg-robbing tests a number of additional Head analyses were carried out which included analyses for multi-element, mercury and copper, carbon and sulphur (which included to total carbon and sulphur analyses, speciation for organic and inorganic carbon and speciation for sulphide and sulphate sulphur).

Of note the total carbon was found to be less than 0.61% and total sulphur insignificant at less than 0.01% as shown in Table 3.

Table 3: Cyclopic Project

Head Analyses – Carbon and Sulphur

Click Image To View Full Size

Copper and mercury values were found to be less than 0.01% and 0.001% respectively.

QUALITY CONTROL AND QUALITY ASSURANCE

All preparation, assaying and metallurgical studies were performed utilizing accepted industry standard procedures.

Sample Preparation and Testwork Procedure

On 6th December 2021, the laboratory facility of Kappes, Cassiday and Associates (KCA) in Reno, Nevada received fifty-seven (57) boxes of core material from the Cyclopic Project. The received material represented four (4) diamond drill holes (CMPQ001 through CMPQ004) and was half split PQ core.

-

The core intervals were inventoried, sorted and weighed. The core intervals for each separate sample were then combined to create a total of six (6) individual samples,

-

Selected samples were then combined to generate two (2) separate composite samples.

-

Each separate composite sample was initially crushed by conventional methods to 100% passing 25 millimetres. Portions of the conventionally crushed material from each composite were then utilized for High Pressure Grinding Roll (HPGR) test work.

-

The remaining minus 25 millimetre material for each composite was then stage crushed by conventional methods to 100% passing 9.5 millimetres.

-

The stage \ crushed material was then size adjusted to a target size of 80% passing 6.3 millimetres.

-

The HPGR and conventionally crushed products were then utilized for head analyses, head screen analyses with assays by size fraction, bottle roll leach test work, agglomeration/compaction test work and column leach test work

-

Column leach tests were conducted for each separate composite sample utilizing the conventionally stage crushed material (100% passing 9.5 millimetres) as well as the HPGR crushed material.

-

The material was leached for 67 or 72 days.

-

Column test extraction results were based upon carbon assays vs. the calculated head (carbon assays + tail assays).

Corporate Update

Gold Basin Resources is also pleased to announce that it has engaged Cologne Communications Corp. to provide investor relations and corporate development services. Vancouver based Michael Rapsch, founder of Cologne Communications, has over 16 years of in-depth corporate communications and investor relations experience. Prior to his engagement with Gold Basin, he worked at several precious metals mining and exploration companies, such as SilverCrest Metals, SilverCrest Mines and Pediment Gold. He was responsible for the implementation, management and execution of all marketing and investor relations programs. Over the years, Mr. Rapsch has built a good rapport with his extensive network of retail and institutional investors across North America and Europe. The initial term of the engagement is for 12 months and the Company has also granted Cologne Communications 100,000 stock options at an exercise price of $0.40 pursuant to the Company’s incentive plan. The grant of the stock options is subject to the approval of the Securities Exchange. Cologne Communications is at arm's length to Gold Basin and has no other relationship with the Company, except pursuant to the engagement.

ABOUTGOLDBASINRESOURCESCORPORATION

Gold Basin Resources is engaged in the business of mineral exploration and the acquisition of mineral property assets in North America, including the Gold Basin Property located in the Gold Basin Mining District, Mohave County, Arizona, which comprises five mineral rights and 294 unpatented mining claims totalling 30.8 square kilometres. A total of 74 new unpatented claims and an Option to acquire additional claims has expanded the total land footprint to 42 square kilometres.

For further information, please visit the Company’s web site at: www.goldbasincorp.com

Gold Basin is a member of Discovery Group, an alliance of public companies focused on the advancement of mineral exploration and mining projects. For more information please visit: discoverygroup.ca.

OnBehalfoftheBoardofDirectors

MichaelPovey

ChiefExecutiveOfficerandDirector

Forfurtherinformation,pleasecontact:

Michael Rapsch, Investor Relations

Phone:1-604-331-5093

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this news release.

QUALIFIEDPERSON

Michael Povey M.Sc BSc.( Hons) M.Aus IMM a qualified person as defined by NI 43-101, has reviewed the scientific and technicalinformationthatformsthebasisforthisnewsreleaseandhasapprovedthedisclosureherein. Mr. Povey has verified the data disclosed in this news release, and has reviewed the applicable report (KCA0210118_CYC01_03 dated 30/12/2021). Mr. Povey is not independent of the Company as he is the CEO and a director of the Company and holdssecuritiesofthe Company.

FORWARD-LOOKINGSTATEMENTS:

This news release contains forward-looking statements and forward-looking information (collectively, "forward looking statements") within the meaning of applicable Canadian and U.S. securities legislation, including the United States Private Securities Litigation Reform Act of 1995. All statements, other than statements of historical fact, included herein including, without limitation, future results from the comprehensive work program on PQ core from the Cyclopic deposit, the Company's expectation that it will be successful in enacting its business plans, and the anticipated business plans and timing of future activities of the Company, are forward looking statements. Although the Company believes that such statements are reasonable, it can give no assurance that such expectations will prove to be correct. Forward-looking statements are typically identified by words such as: "believes", "will", "expects", "anticipates", "intends", "estimates", "plans", "may", "should", "potential", "scheduled", or variations of such words and phrases and similar expressions, which, by their nature, refer to future events or results that may, could, would, might or will occur or be taken or achieved. In making the forward-looking statements in this news release, the Company has applied several material assumptions, including without limitation, that that there will be investor interest in future financings, market fundamentals will result in sustained precious metals demand and prices, the receipt of any necessary permits, licenses and regulatory approvals in connection with the future exploration and development of the Company's projects in a timely manner, the availability of financing on suitable terms for the exploration and development of the Company's projects and the Company's ability to comply with environmental, health and safety laws.

TheCompanycautionsinvestorsthatanyforward-lookingstatementsbytheCompanyarenotguaranteesoffutureresultsorperformance,andthatactualresultsmaydiffermateriallyfromthoseinforward-lookingstatementsasaresult of various factors, including, operating and technical difficulties in connection with mineral exploration anddevelopmentactivities,actualresultsofexplorationactivities,theestimationorrealizationofmineralreservesandmineral resources, the inability of the Company to obtain the necessary financing required to conduct its businessand affairs, as currently contemplated, the timing and amount of estimated futureproduction, the costs ofproduction, capital expenditures, the costs and timing of the development of new deposits, requirements foradditionalcapital,futurepricesofpreciousmetals,changesingeneraleconomicconditions,changesinthefinancialmarkets and in the demand and market price for commodities, lack of investor interest in future financings,accidents, labour disputes and other risks of the mining industry, delays in obtaining governmental approvals,permits or financing or in the completion of development or construction activities, risks relating to epidemics orpandemicssuchasCOVID–19,includingtheimpactofCOVID–19ontheCompany'sbusiness,financialconditionandresults of operations, changes in laws, regulations and policies affecting mining operations, title disputes, theinability of the Company to obtain any necessary permits, consents, approvals or authorizations, including of theTSX VentureExchange,thetimingandpossibleoutcomeofanypendinglitigation,environmentalissuesandliabilities,andrisksrelatedtojointventureoperations,andotherrisksanduncertaintiesdisclosedintheCompany'slatest Management's Discussion and Analysis and filed with certain securities commissions in Canada. All of theCompany'sCanadianpublicdisclosurefilingsmaybeaccessedviawww.sedar.comandreadersareurgedtoreviewthesematerials.

Readers are cautioned not to place undue reliance on forward-looking statements. The Company undertakes noobligation to update any of the forward-looking statements in this news release or incorporated by referenceherein,except as otherwise requiredbylaw.

Copyright (c) 2022 TheNewswire - All rights reserved.