MONTREAL, Jan. 31, 2024 (GLOBE NEWSWIRE) -- HPQ Silicon Inc. (“HPQ” or the “Company”) (TSX-V: HPQ) (OTCQB: HPQFF) (FRA: O08), a technology company specializing in green engineering of silica and silicon-based materials, is pleased to update its shareholders that it signed an NDA with an undisclosed party related to its Fumed Silica initiative.

Following our press release of January 10, 2024, we were approached by an Industrial Group interested in assessing the commercial potential of our Fumed Silica Reactor (FSR) process. To facilitate more formal discussions, HPQ's wholly owned subsidiary, HPQ Silica Polvere Inc. (HPQ Polvere), along with the technology provider and equipment supplier, PyroGenesis Canada Inc. (TSX: PYR) (OTCQX: PYRGF) (FRA: 8PY) (PyroGenesis) signed a Non-Disclosure Agreement (NDA) [1] with the Industrial Group.

The purpose of the NDA is twofold:

- First, it will enable both parties, HPQ Polvere and the Industrial Group, to conduct mutual due diligence, and

- Second, it will enable both parties to assess the commercial and economic potential for a more formal collaboration regarding the construction and operation of a 1,000 tonnes per year (TPY) Fumed Silica Reactor to be built by PyroGenesis.

“The NDA, stands as tangible proof of the commercial interest in the potential of our proprietary Fumed Silica Reactor technology," said Mr. Bernard Tourillon, President and CEO of HPQ Silica Polvere Inc. and HPQ Silicon Inc. "While, at this stage, we have no guarantee that a formal commercial venture will emerge from these discussions, we are immensely encouraged by the ongoing talks.

HPQ POLVERE'S DISRUPTIVE ADVANTAGES ATTRACT INDUSTRIAL INTEREST

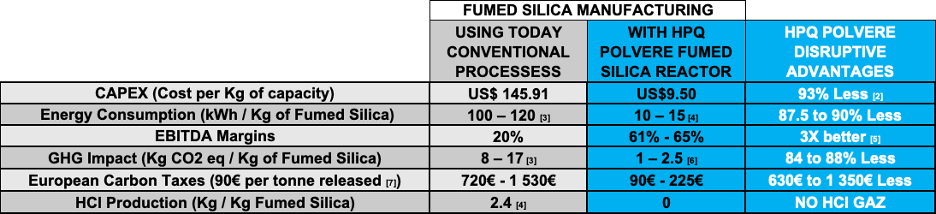

The table below clearly illustrates the numerous disruptive advantages of HPQ Polvere's Fumed Silica Reactor (FSR) compared to traditional Fumed Silica Manufacturing. The significant opportunities presented contributed to the interest from the Industrial Group.

A STEP FORWARD IN IMPLEMENTING OUR INCREMENTAL COMMERCIALISATION STRATEGY

The commercial imperative to construct a 1,000 tonnes per year (TPY) Fumed Silica Reactor, driven by the anticipated demand for low carbon fumed silica materials, is evident. HPQ Polvere's commercialization strategy centers on scaling up capacity to meet this demand, including the addition of other 1,000 TPY Fumed Silica Reactor.

“We are keenly interested in the possibility of implementing a pathway to commercialization and monetization of our Fumed Silica Reactor process that could be less dilutive for HPQ shareholders,” Mr. Tourillon further emphasized, “This potential partnership could help us reach that goal faster.”

REFERENCE SOURCES

| [1] |

PyroGenesis participation in the NDA agreements is done at HPQ's express request.

|

| [2] |

Traditional Fumed Silica manufacturing involves a complex three-step process. Step 1: Conversion of Quartz to Silicon Metal (Si), with an average Capex of around US$9.38 per kilogram of annual capacity (for reference, the PCC BakkiSilicon Plant in Iceland cost US$300 million for an annual capacity of 32,000 tonnes). Step 2: Conversion of Si to Silicon Tetrachloride (SiCl4), with an average Capex of approximately US$125.00 per kilogram of annual capacity (e.g., Wacker Chemie AG Polysilicon's US production plant cost US$2.5 billion for an annual capacity of 20,000 tonnes). Step 3: Burning Silicon Tetrachloride (SiCl4) with Hydrogen and Oxygen to produce Fumed Silica (SiO2), incurring an average Capex of around US$11.54 per kilogram of annual capacity (Wacker Chemie AG's US Fumed Silica plant cost US$150 million for an annual capacity of 20,000 tonnes). The combined Capex for these three steps averages at US$145.92 per kilogram of annual capacity. According to a rough order of magnitude study by PyroGenesis, our one-step process for making Fumed Silica is estimated to have an average Capex per kilogram of annual capacity between US$9.00 and US$10.00, which is approximately 93% less than traditional processes.

|

| [3] |

Frischknecht, Rolf, et al. "Life cycle inventories and life cycle assessment of photovoltaic systems." International Energy Agency (IEA) PVPS Task 12 (2020).

|

| [4] |

PyroGenesis Canada Inc

|

| [5] |

Average EBITDA margins of 20% are derived from two sources, with Link #1 leading to Source #1 and Link #2 leading to Source #2 (Specialty Additives division). Management has calculated the EBITDA margins for the Fumed Silica Reactor (FSR) based on data derived from third party sources and publicly available information. These figures will be updated upon completion of the pilot testing phase. The 5% range in HPQ Polvere's EBITDA margins considers PyroGenesis' option to convert its 10% royalties into a 50% ownership stake in HPQ Polvere's remaining equity.

|

| [6] |

The 1 Kg eq of CO2 per Kg of Fumed Silica is based on Hydro Quebec data that indicate in Quebec 1.3 g of CO2 are generated eq per KWh. While the 2.5 is based on the Canadian average for electricity generation carbon intensity of 150 g per KWh.

|

| [7] |

The Wall Street Journal article, April 18, 2023, “World’s First Carbon Import Tax Approved by EU Lawmakers”

|

About PyroGenesis Canada Inc.

PyroGenesis Canada Inc., a high-tech company, is a leader in the design, development, manufacture and commercialization of advanced plasma processes and sustainable solutions which reduce greenhouse gases (GHG) and are economically attractive alternatives to conventional “dirty” processes. PyroGenesis has created proprietary, patented, and advanced plasma technologies that are being vetted and adopted by multiple multibillion dollar industry leaders in three massive markets: iron ore pelletization, aluminum, waste management, and additive manufacturing. With a team of experienced engineers, scientists and technicians working out of its Montreal office, and its 3,800 m2 and 2,940 m2 R&D and manufacturing facilities, PyroGenesis maintains its competitive advantage by remaining at the forefront of technology development and commercialization. The operations are ISO 9001:2015 and AS9100D certified, having been ISO certified since 1997. For more information, please visit: www.pyrogenesis.com

About HPQ Silicon

HPQ Silicon Inc. (TSX-V: HPQ) is a Quebec-based TSX Venture Exchange Tier 1 Industrial Issuer.

HPQ is developing, with the support of world-class technology partners PyroGenesis Canada Inc. and NOVACIUM SAS, new green processes crucial to make the critical materials needed to reach net zero emissions.

HPQ activities are centred around the following four (4) pillars:

|

1) |

Becoming a green low-cost (Capex and Opex) manufacturer of Fumed Silica using the FUMED SILICA REACTOR, a proprietary technology owned by HPQ being developed for HPQ by PyroGenesis.

|

|

2) |

Becoming a zero CO2 low-cost (Capex and Opex) producer of High Purity Silicon (2N+ to 4N) using our PUREVAPTM “Quartz Reduction Reactors” (QRR), a proprietary technology owned by HPQ being developed for HPQ by PyroGenesis.

|

|

3) |

Becoming a producer of silicon-based anode materials for battery applications with the assistance of NOVACIUM SAS.

|

|

4) |

HPQ SILICON affiliate NOVACIUM SAS is developing a low carbon, chemical base on demand and high-pressure autonomous hydrogen production system.

|

For more information, please visit HPQ Silicon web site.

Disclaimers:

This press release contains certain forward-looking statements, including, without limitation, statements containing the words "may", "plan", "will", "estimate", "continue", "anticipate", "intend", "expect", "in the process" and other similar expressions which constitute "forward-looking information" within the meaning of applicable securities laws. Forward-looking statements reflect the Company's current expectation and assumptions and are subject to a number of risks and uncertainties that could cause actual results to differ materially from those anticipated. These forward-looking statements involve risks and uncertainties including, but not limited to, our expectations regarding the acceptance of our products by the market, our strategy to develop new products and enhance the capabilities of existing products, our strategy with respect to research and development, the impact of competitive products and pricing, new product development, and uncertainties related to the regulatory approval process. Such statements reflect the current views of the Company with respect to future events and are subject to certain risks and uncertainties and other risks detailed from time-to-time in the Company's ongoing filings with the security’s regulatory authorities, which filings can be found at www.sedar.com. Actual results, events, and performance may differ materially. Readers are cautioned not to place undue reliance on these forward-looking statements. The Company undertakes no obligation to publicly update or revise any forward-looking statements either as a result of new information, future events or otherwise, except as required by applicable securities laws.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

This News Release is available on the company's CEO Verified Discussion Forum, a moderated social media platform that enables civilized discussion and Q&A between Management and Shareholders.

Source: HPQ Silicon Inc.

For further information contact:

Bernard J. Tourillon, Chairman, President, and CEO Tel +1 (514) 846-3271

Patrick Levasseur, Director Tel: +1 (514) 262-9239

Email: Info@hpqsilicon.com

A table accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/f7451599-3d88-48be-824b-369d0c026e12