TORONTO, Oct. 15, 2024 (GLOBE NEWSWIRE) -- Xanadu Mines Ltd (ASX: XAM, TSX: XAM) (Xanadu, XAM or the Company) is pleased to report an increase in the Mineral Resource Estimate (Resource, Mineral Resource Estimate or MRE) and a Maiden Ore Reserve for its flagship copper-gold project at Kharmagtai, in the South Gobi region of Mongolia (Figure 1 andTable 1). The MRE update incorporates a revised cut-off grade to align to the marginal cut-off grade in the Kharmagtai Pre-Feasibility Study (PFS). The updated Mineral Resource Estimate and Maiden Ore Reserve are reported in concert with the PFS announced on 14 October 2024.

Highlights

- Kharmagtai Maiden Ore Reserve reported with approximately 1.6Mt Cu and 4.0Moz Au, comprised of Indicated material within the pit shells in the Kharmagtai PFS, but excluding the final pit phase at White Hill which is primarily driven by Inferred material.

- Significant increase in Kharmagtai MRE as Kharmagtai adopts the PFS1 marginal cut-off grade for economic extraction within the open pit.

- Open Pit Resource cut-off reduced from 0.20% CuEq to 0.13% CuEq to match the PFS mine plan marginal cut-off grade.

- Contained copper increase from 3.8Mt to4.7Mt Cu, or an increase of 0.9Mt Cu.

- Contained gold increase from 9.3Moz to 11Moz Au, or an increase of 1.7Moz Au.

- No additional drilling has been completed since August 2024. The MRE growth is exclusively due to change in cut-off grade aligned to PFS1 calculations by Mining Plus.

Xanadu’s Executive Chairman and Managing Director, Mr Colin Moorhead, said“We are pleased to report Kharmagtai Maiden Ore Reserve in concert with the PFS results announced today. We have also aligned the Mineral Resource to the PFS marginal cut-off grades, which demonstrates the sensitivity of this project to that cut-off grade and the significant scale of Kharmagtai, which remains open along strike and at depth with significant growth potential.”

Table 1:Comparison October 2024 vs August 2024 Mineral Resource Estimate2

Resource

|

Cutoff

(% CuEq)

|

Classification

|

Tonnes (Mt)

|

Grades |

Contained Metal |

| CuEq (%) |

Cu (%) |

Au (g/t) |

CuEq (Mlbs) |

CuEq (kt) |

Cu (kt) |

Au (koz) |

October 2024

|

0.13 (OC)

0.30 (UG)

|

Indicated |

1,300 |

0.30 |

0.22 |

0.17 |

8,800 |

4,000 |

2,900 |

7,100 |

| Inferred |

900 |

0.28 |

0.21 |

0.13 |

5,600 |

2,500 |

1,900 |

4,000 |

|

|

|

|

|

|

|

|

|

August 2024

|

0.20 (OC)

0.30 (UG)

|

Indicated |

890 |

0.37 |

0.26 |

0.21 |

7,300 |

3,300 |

2,300 |

6,000 |

| Inferred |

590 |

0.34 |

0.25 |

0.17 |

4,500 |

2,000 |

1,500 |

3,300 |

|

|

|

|

|

|

|

|

|

Notes:

- CuEq (lbs and t) accounts for Au (g/t) value and CuEq (t) must not be totalled to Au ounces

- Figures may not sum due to rounding

- Significant figures do not imply an added level of precision

- Resource constrained by 0.1%CuEq reporting solid in line with geological analysis by XAM

- Resource constrained by RV1400fpit (coded field equal to 1)

- Cut-off for Open Cut uses 0.13% CuEq, the marginal mine cut-off per the October 2024 PFS. Cut-off for Underground remains unchanged at 0.30% CuEq.

- Resource CuEq equation (CuEq=Cu+Au*0.60049*0.86667) where Au at USD$1400/oz and Cu at USD$3.4/lb was employed according to the Clients' (XAM) direction.

- Au recovery is relative with Cu rec=90% and Au rec=78% (rel Au rec=78/90=86.667% with number according to the Clients' (XAM) direction

- Underground Resource "other 0p2 and 0p3" NOT inside RV1400fpit above and below nominated mRL level by deposit as follows SH>=720mRL, WH>=915mRL, CH>=1100mRL, ZA>=920mRL, ZE>=945mRL, PE>=1100mRL and GE>=845mRL

- Model: KH_ALL_GLOBAL_OKMOD_FINAL_V3_FORCLIENT_140624_inRV1400fpit

Table 2: Ore Reserve by Classification (Open Cut)

Classification

|

Tonnes (Mt)

|

Grades |

Contained Metal |

| Cu (%) |

Au (g/t) |

Cu (kt) |

Au (koz) |

| Proved |

0 |

0 |

0 |

0 |

0 |

| Probable |

730 |

0.21 |

0.17 |

1,600 |

4,000 |

| Total |

730 |

0.21 |

0.17 |

1,600 |

4,000 |

Notes:

- Figures may not sum due to rounding

- Significant figures do not imply an added level of precision

- Ore Reserve constrained by Kharmagtai PFS mine plan inventory3

- Cut-off for Open Cut Ore Reserve uses 0.13% CuEq, the marginal breakeven mine cut-off per the October 2024 PFS.

- Reserve CuEq equation (CuEq=Cu+Au*0.7039Au) where Au at USD$1900/oz and Cu at USD$4.0/lb was employed according to the Clients' (XAM) direction.

- Au recovery is relative with Cu rec=80% and Au rec=81% according to the Clients' (XAM) direction

MINERAL RESOURCE ESTIMATE UPDATE OVERVIEW

Xanadu engaged independent consultants, Spiers Geological Consultants (SGC), to prepare an updated Resource for Kharmagtai. The Resource has been reported in accordance with the JORC Code 2012, is effective as of 31st July 2024, and is shown in full in Tables 3 to 5.

This Resource is an update to the August 2024 Mineral Resource Estimate, which reduces the open pit cut-off grade from 0.20% CuEq to 0.13% CuEq in line with the PFS marginal breakeven cut-off grade. Open cut resources are reported within the same revenue factor 1.4 pit shell from the Kharmagtai PFS. The revenue factor 1.4 pit shell is being used to define RPEEE for the open pit-able MRE at Kharmagtai.

SGC considers that data collection techniques are consistent with industry best practice and are suitable for use in the preparation of a Resource to be reported in accordance with JORC Code 2012. Available quality assurance and quality control (QA/QC) data supports the use of the input data provided by Xanadu.

The Resource is considered to have reasonable prospects for eventual economic extraction (RPEEE) on the following basis:

- the deposit is located in a favourable mining jurisdiction, with no known impediments to land access or tenure status;

- the volume, orientation and grade of the Resource is amenable to mining extraction via traditional open-pit and underground methods; and

- a Scoping Study4 and PFS5 have been reported to ASX that demonstrate Kharmagtai economic viability as an open pit mine within the revenue factor 1.4 shell that constrains the open cut Resource using the selected marginal cut-off grade, at a range of metal prices and assumptions.

- The PFS has reported a maiden Ore Reserve based on Indicated Resource within the Open Cut Mineral Resource Estimate.

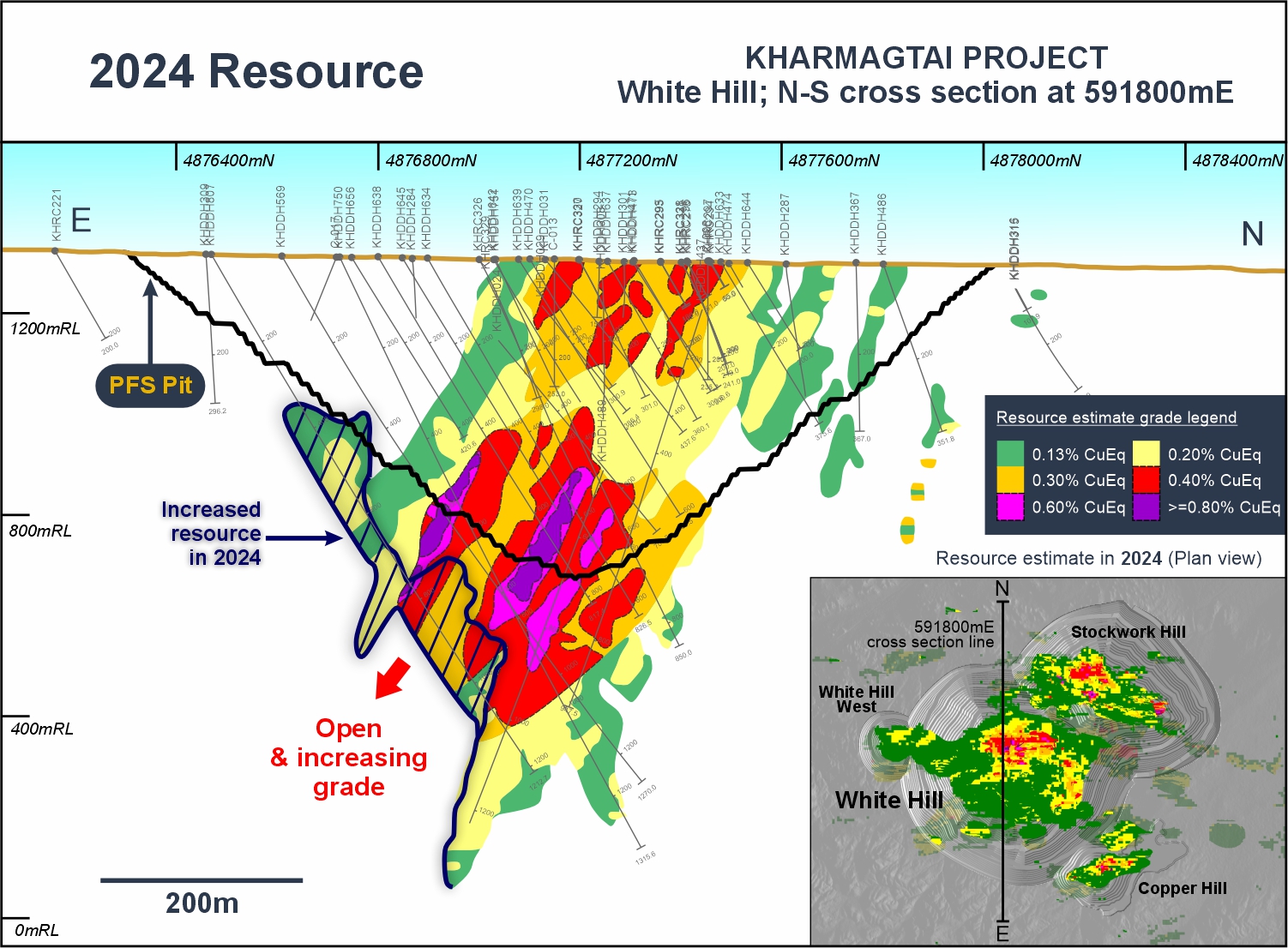

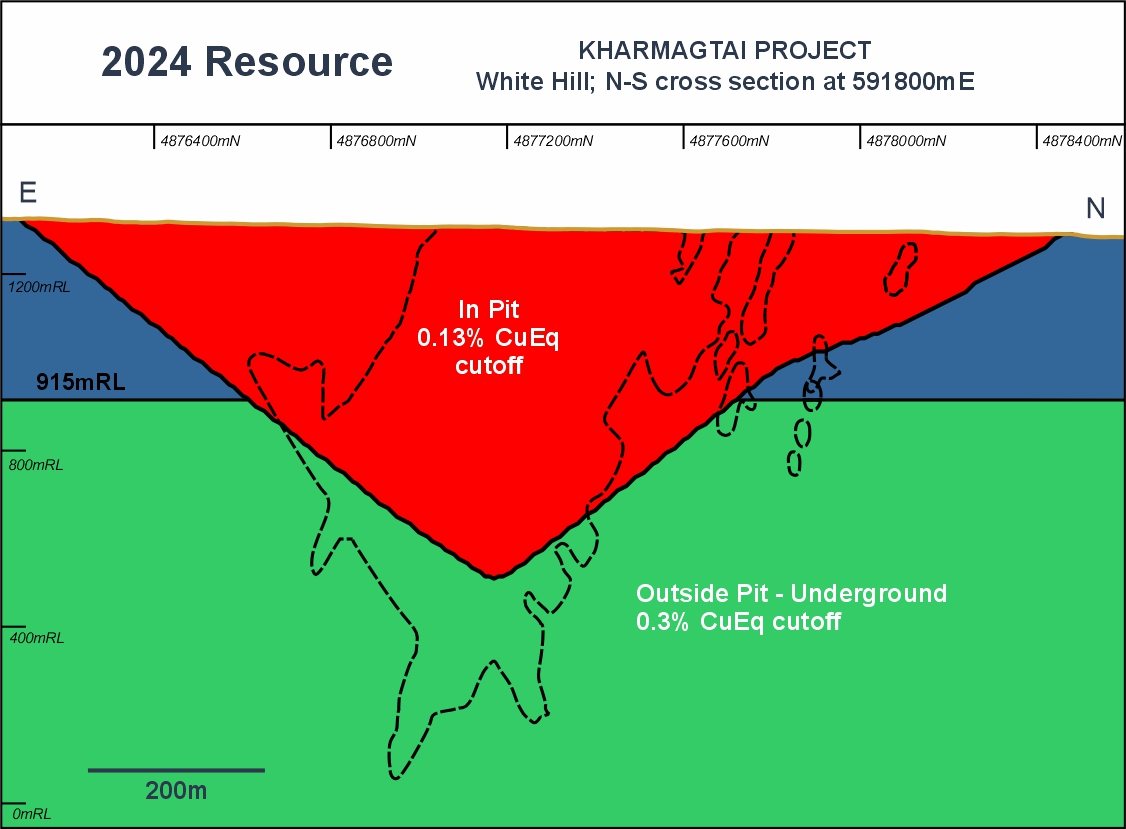

The Resource models are well understood and there is substantial upside potential to be realised by better understanding the economics of the deposit. As demonstrated in the images below, significant volumes of mineralisation have been modelled that fall outside of the constraining pit wireframe. These parts of the model will be targeted for further investigation through economic studies to assess if more of this material can be brought into the Mineral Resource.

The total Mineral Resource Estimate includes material classified as oxide totalling 121Mt @ 0.31% CuEq which can be found in Table 5.

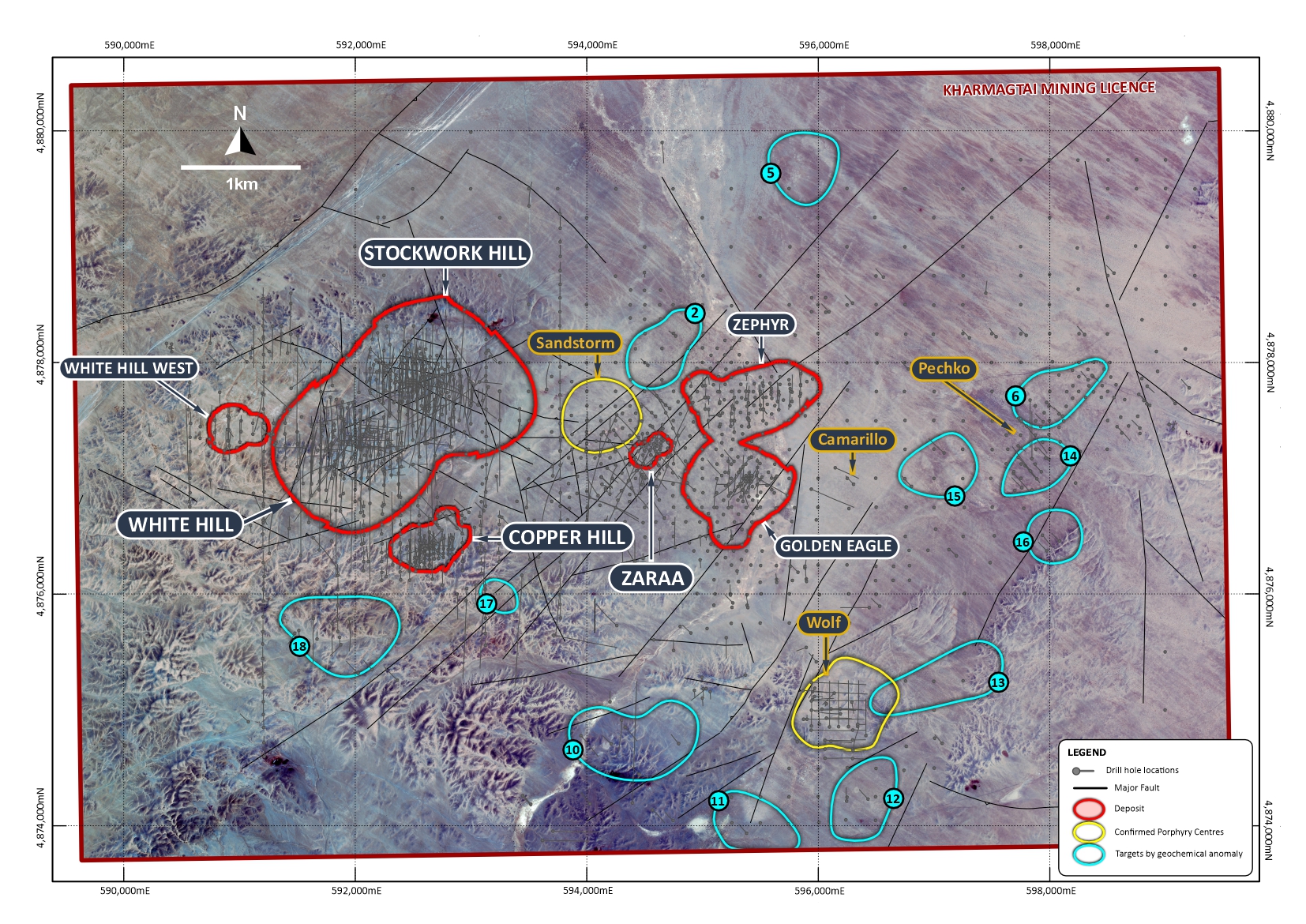

Figure 1: Plan view of the Kharmagtai district. Deposit outlines define the edges of the PFS open pit designs. Confirmed porphyry centres define zones where mineralised porphyry has been intersected in drilling. Geochemical targets represent areas of anomalous copper and gold.

Figure 2: Cross section through the White Hill Deposit showing open nature of the White Hill deposit with grades generally increasing with depth.

Figure 3: Schematic Cross Sections showing the cut-off grade reporting boundaries at White Hill. Red zone represents MRE open pit potential with a cutoff of 0.13% CuEq, blue area “outside open pit” and green area represents the area defined as underground potential with a 0.3% CuEq cutoff applied. These are shown separately as previous MRE’s used this 915mRL level as the change from Open Pit and Underground.

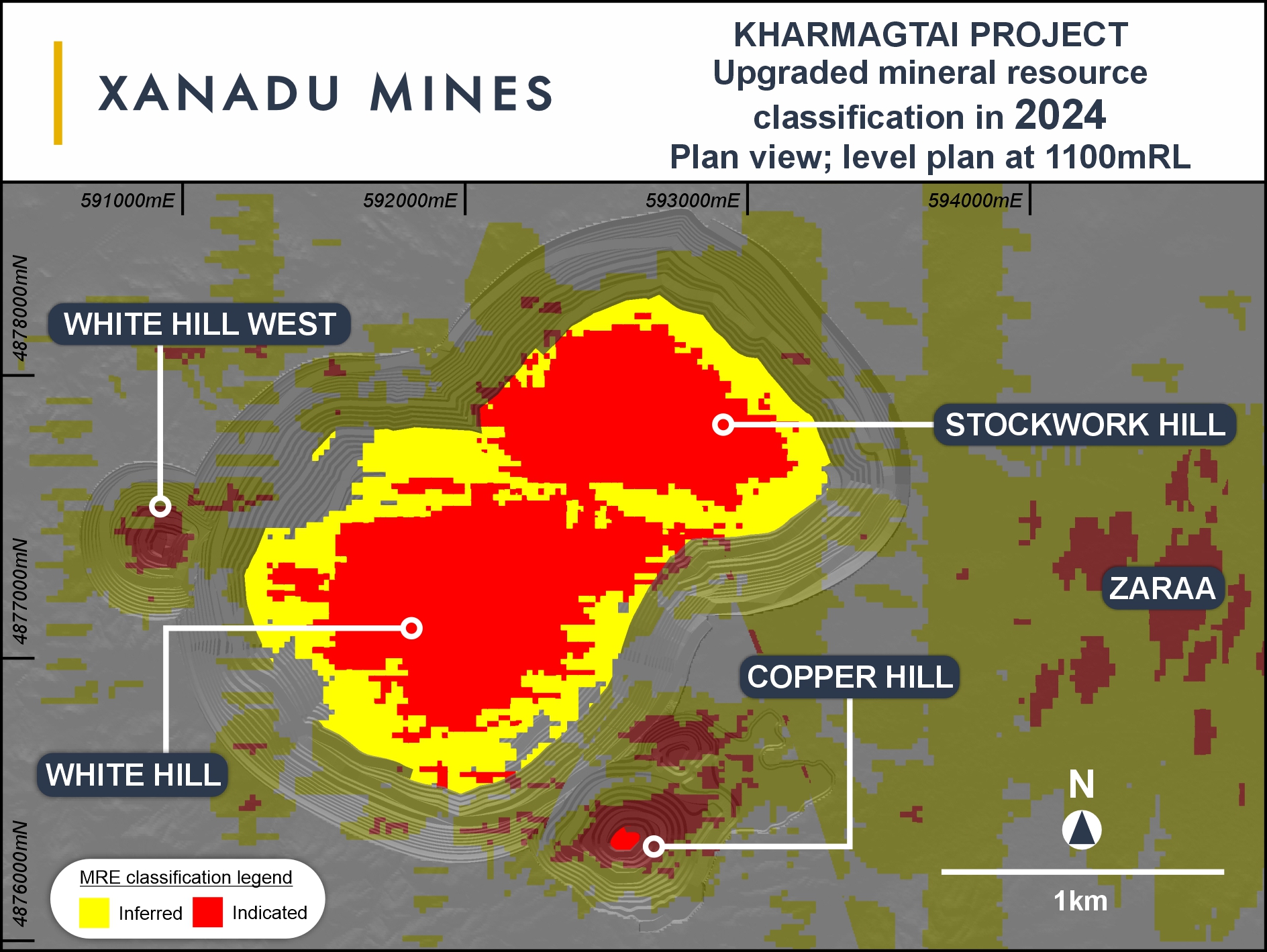

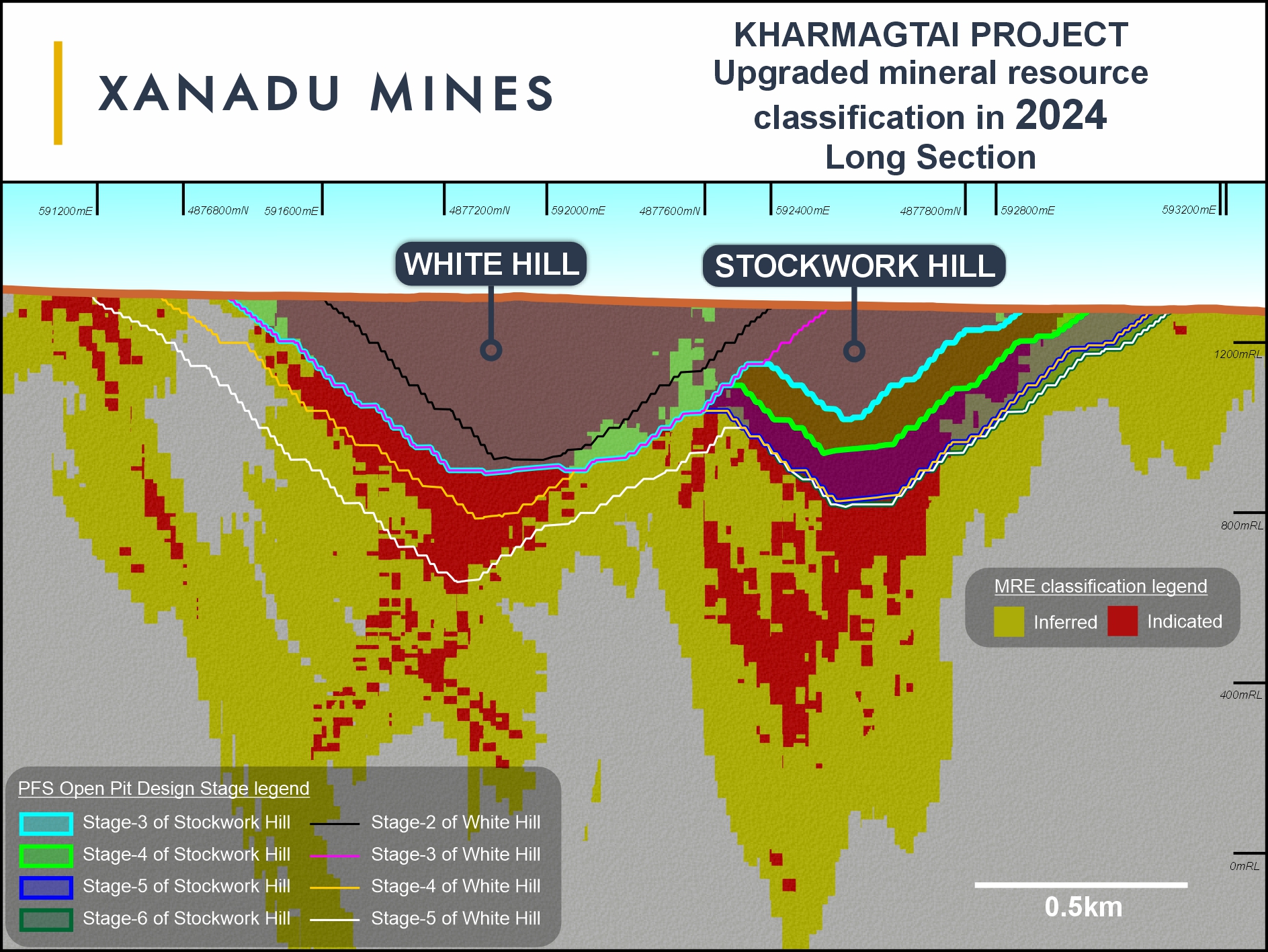

Figure 4: Illustration of resource classification within the 2024 PFS pit shells, plan view.

Figure 5: Illustration of resource classification within the 2024 PFS pit shells, long section.

Table 3: Kharmagtai Project – Potential Open Pit Mineral Resource Estimate October 2024 reported at 0.13% CuEq cut-off grade, within the revenue factor 1.4 pit, by resource classification.

Deposit

|

Classification

|

Tonnes (Mt)

|

Grades |

Contained Metal |

| CuEq (%) |

Cu (%) |

Au (g/t) |

CuEq (Mlbs) |

CuEq (kt) |

Cu (kt) |

Au (koz) |

| Stockwork Hill |

Indicated

|

314 |

0.35 |

0.23 |

0.23 |

2,445 |

1,110 |

730 |

2,310 |

| White Hill |

704 |

0.30 |

0.23 |

0.13 |

4,578 |

2,080 |

1,590 |

2,980 |

| Copper Hill |

65 |

0.29 |

0.21 |

0.15 |

420 |

190 |

140 |

310 |

| Zaraa |

84 |

0.23 |

0.15 |

0.15 |

424 |

190 |

130 |

410 |

| Golden Eagle |

62 |

0.24 |

0.11 |

0.25 |

334 |

150 |

70 |

500 |

| Zephyr |

49 |

0.23 |

0.14 |

0.17 |

243 |

110 |

70 |

260 |

| Exploration Potential |

|

|

|

|

|

|

|

|

| Total Indicated |

1,279 |

0.30 |

0.21 |

0.16 |

8,447 |

3,830 |

2,730 |

6,770 |

| Stockwork Hill |

Inferred

|

74 |

0.22 |

0.14 |

0.14 |

352 |

160 |

100 |

340 |

| White Hill |

361 |

0.26 |

0.21 |

0.10 |

2,100 |

950 |

770 |

1,100 |

| Copper Hill |

30 |

0.18 |

0.15 |

0.06 |

120 |

50 |

40 |

60 |

| Zaraa |

195 |

0.26 |

0.18 |

0.15 |

1,123 |

510 |

350 |

970 |

| Golden Eagle |

50 |

0.21 |

0.11 |

0.20 |

230 |

100 |

50 |

320 |

| Zephyr |

39 |

0.19 |

0.12 |

0.14 |

165 |

70 |

50 |

180 |

| Exploration Potential |

|

|

|

|

|

|

|

|

| Total Inferred |

751 |

0.25 |

0.18 |

0.12 |

4,097 |

1,860 |

1,380 |

2,970 |

Notes:

- CuEq (lbs and t) accounts for Au (g/t) value and CuEq (t) must not be totalled to Au ounces

- Figures may not sum due to rounding

- Significant figures do not imply an added level of precision

- Resource constrained by 0.1%CuEq reporting solid inline with geological analysis by XAM

- Resource constrained by RV1400fpit (coded field equal to 1)

- CuEq equation (CuEq=Cu+Au*0.60049*0.86667) where Au at USD$1400/oz and Cu at USD$3.4/lb was employed according to the Clients' (XAM) direction.

- Au recovery is relative with Cu rec=90% and Au rec=78% (rel Au rec=78/90=86.667% with number according to the Clients' (XAM) direction

- Model: KH_ALL_GLOBAL_OKMOD_FINAL_V3_FORCLIENT_140624_inRV1400fpit

Table 4: Kharmagtai Project – Potential Underground Mineral Resource Estimate October 2024, reported at 0.3%CuEq cut-off grade, outside the revenue factor 1.4 pit, by resource classification.

Deposit

|

Classification

|

Tonnes (Mt)

|

Grades |

Contained Metal |

| CuEq (%) |

Cu (%) |

Au (g/t) |

CuEq (Mlbs) |

CuEq (kt) |

Cu (kt) |

Au (koz) |

| Stockwork Hill |

Indicated

|

14 |

0.46 |

0.30 |

0.29 |

138 |

60 |

40 |

130 |

| White Hill |

11 |

0.41 |

0.35 |

0.12 |

104 |

50 |

40 |

40 |

| Copper Hill |

- |

0.33 |

0.23 |

0.19 |

2 |

- |

- |

- |

| Zaraa |

13 |

0.47 |

0.33 |

0.28 |

132 |

60 |

40 |

110 |

| Golden Eagle |

- |

- |

- |

- |

- |

- |

- |

- |

| Zephyr |

- |

- |

- |

- |

- |

- |

- |

- |

| Exploration Potential |

|

|

|

|

|

|

|

|

| Total Indicated |

38 |

0.45 |

0.32 |

0.24 |

376 |

170 |

120 |

290 |

| Stockwork Hill |

Inferred

|

26 |

0.42 |

0.32 |

0.19 |

238 |

110 |

80 |

160 |

| White Hill |

57 |

0.38 |

0.32 |

0.12 |

478 |

220 |

180 |

210 |

| Copper Hill |

- |

0.38 |

0.34 |

0.09 |

4 |

- |

- |

- |

| Zaraa |

81 |

0.42 |

0.30 |

0.23 |

750 |

340 |

240 |

610 |

| Golden Eagle |

- |

- |

- |

- |

- |

- |

- |

- |

| Zephyr |

- |

0.40 |

0.06 |

0.67 |

1 |

- |

- |

- |

| Exploration Potential |

|

|

|

|

|

|

|

|

| Total Inferred |

164 |

0.41 |

0.31 |

0.19 |

1,471 |

670 |

500 |

980 |

Notes:

- CuEq (lbs and t) accounts for Au (g/t) value and CuEq (t) must not be totalled to Au ounces

- Figures may not sum due to rounding

- Significant figures do not imply an added level of precision

- Resource constrained by 0.1%CuEq reporting solid in line with geological analysis by XAM

- Resource NOT constrained by RV1400fpit (coded field equal to 1)

- CuEq equation (CuEq=Cu+Au*0.60049*0.86667) where Au at USD$1400/oz and Cu at USD$3.4/lb was employed according to the Clients' (XAM) direction.

- Au recovery is relative with Cu rec=90% and Au rec=78% (rel Au rec=78/90=86.667% with number according to the Clients' (XAM) direction

- Resource "other 0p2 and 0p3" NOT inside RV1400fpit above and below nominated mRL level by deposit as follows SH>=720mRL, WH>=915mRL, CH>=1100mRL, ZA>=920mRL, ZE>=945mRL, PE>=1100mRL and GE>=845mRL

- Model: KH_ALL_GLOBAL_OKMOD_FINAL_V3_FORCLIENT_140624_inRV1400fpit

Table 5: Kharmagtai Project – Oxide Open Pit Mineral Resource Estimate October 2024, reported at 0.13% CuEq cut-off grade, inside the revenue factor 1.4 pit, by resource classification.

Deposit

|

Classification

|

Tonnes (Mt)

|

Grades |

Contained Metal |

| CuEq (%) |

Cu (%) |

Au (g/t) |

CuEq (Mlbs) |

CuEq (kt) |

Cu (kt) |

Au (koz) |

| Stockwork Hill |

Indicated

|

14 |

0.46 |

0.30 |

0.29 |

138 |

60 |

40 |

130 |

| White Hill |

44 |

0.26 |

0.19 |

0.12 |

249 |

110 |

90 |

170 |

| Copper Hill |

10 |

0.32 |

0.24 |

0.15 |

70 |

30 |

20 |

50 |

| Zaraa |

2 |

0.22 |

0.10 |

0.23 |

10 |

- |

- |

20 |

| Golden Eagle |

6 |

0.27 |

0.10 |

0.33 |

34 |

20 |

10 |

60 |

| Zephyr |

5 |

0.25 |

0.16 |

0.18 |

28 |

10 |

10 |

30 |

| Exploration Potential |

|

|

|

|

|

|

|

|

| Total Indicated |

82 |

0.30 |

0.21 |

0.17 |

532 |

240 |

170 |

450 |

| Stockwork Hill |

Inferred

|

26 |

0.42 |

0.32 |

0.19 |

238 |

110 |

80 |

160 |

| White Hill |

4 |

0.21 |

0.16 |

0.10 |

20 |

10 |

10 |

10 |

| Copper Hill |

3 |

0.18 |

0.15 |

0.05 |

13 |

10 |

- |

10 |

| Zaraa |

1 |

0.19 |

0.10 |

0.18 |

3 |

- |

- |

- |

| Golden Eagle |

4 |

0.20 |

0.09 |

0.21 |

18 |

10 |

- |

30 |

| Zephyr |

- |

0.15 |

0.10 |

0.11 |

- |

- |

- |

- |

| Exploration Potential |

|

|

|

|

|

|

|

|

| Total Inferred |

40 |

0.34 |

0.25 |

0.17 |

297 |

130 |

100 |

220 |

|

|

|

|

|

|

|

|

|

|

Notes

- CuEq (lbs and t) accounts for Au (g/t) value and CuEq (t) must not be totalled to Au ounces

- Figures may not sum due to rounding

- Significant figures do not imply an added level of precision

- Resource constrained by 0.1%CuEq reporting solid in line with geological analysis by XAM

- Resource constrained by RV1400fpit (coded field equal to 1)

- CuEq equation (CuEq=Cu+Au*0.60049*0.86667) where Au at USD$1400/oz and Cu at USD$3.4/lb was employed according to the Clients' (XAM) direction.

- Au recovery is relative with Cu rec=90% and Au rec=78% (rel Au rec=78/90=86.667% with number according to the Clients' (XAM) direction

- Model: KH_ALL_GLOBAL_OKMOD_FINAL_V3_FORCLIENT_140624_inRV1400fpit

MRE Supporting Information

Geology and Geological Interpretation

Geological data has been collected in a consistent manner that has allowed the development of geological models to support the Mineral Resource estimate. Copper and gold mineralisation is controlled by porphyry phases, oxidation zone, the level of veining, breccia, country rocks and barren dykes.

- Solid geological models were generated in Leapfrog for each of the deposits using the following methodology

- Composite copper and gold grades to 10m intervals

- Define cut-offs using changes in slope of histograms and cumulative log plots

- Create raw grade shells for these using implicit numeric modelling (e.g. 800, 1500 and 4000ppm Cu)

- Define the main dividing features/structures between populations (clusters of grade)

- Build these structures in detail using grade, lithology, and structural information

- For each compartment/fault block

- Group the main lithologies into “like units”

- Build geological shapes from these units

- Re-build the grade shells within each compartment using information from the geological shapes to help constrain the grade shapes

- Once each compartment was built, they were assessed in context with each other and refined so that the models made geological sense.

- Geological interpretation and wireframing were based on sampling results of drill holes and trenches, which were logged at 2 m intervals (average, tied to lithological boundaries during logging).

- SGC do not believe that the effect of alternative interpretations will have a material impact on the overall Mineral Resource Estimates.

- The geological interpretation is considered robust & alternative interpretations are not considered to have a material effect on the Mineral Resource. No alternate interpretations are proposed as geological confidence in the model is moderate to high. As additional geological data is collected from additional drilling, the geological interpretation will be continually updated.

- The factors affecting continuity both of grade and geology are most likely to be associated with structural controls and local complexity the knowledge of which is considered at a moderate level with the current spacing of information. The broad approach to the mineralisation modelling is an attempt to model an unbiased interpretation.

Sampling techniques

- Representative ½ core samples were split from PQ, HQ & NQ diameter diamond drill core on site using rock saws, on a routine 2m sample interval that also honours lithological/intrusive contacts.

- The orientation of the cut line is controlled using the core orientation line ensuring uniformity of core splitting wherever the core has been successfully oriented.

- Sample intervals are defined and subsequently checked by geologists, and sample tags are attached (stapled) to the plastic core trays for every sample interval.

- Reverse Circulation (RC) chip samples are ¼ splits from one meter (1m) intervals using a 75%:25% riffle splitter to obtain a 3kg sample

- RC samples are uniform 2m samples formed from the combination of two ¼ split 1m samples.

Sub-Sampling Techniques and Sample Preparation

- All drill core samples are ½ core splits from either PQ, HQ or NQ diameter cores. A routine 2m sample interval is used, but this is varied locally to honour lithological/intrusive contacts. The minimum allowed sample length is 30cm.

- Core is appropriately split (onsite) using diamond core saws with the cut line routinely located relative to the core orientation line (where present) to provide consistency of sample split selection.

- The diamond saws are regularly flushed with water to minimize potential contamination.

- A field duplicate ¼ core sample is collected every 30th sample to ensure the “representivity of the in-situ material collected”. The performance of these field duplicates is routinely analysed as part of Xanadu’s sample QC process.

- Routine sample preparation and analyses of DDH samples were carried out by ALS Mongolia LLC (ALS Mongolia), who operates an independent sample preparation and analytical laboratory in Ulaanbaatar.

- All samples were prepared to meet standard quality control procedures as follows: Crushed to 75% passing 2mm, split to 1kg, pulverised to 85% passing 200 mesh (75 microns) and split to 150g sample pulp.

- ALS Mongolia Geochemistry labs quality management system is certified to ISO 9001:2008.

- The sample support (sub-sample mass and comminution) is appropriate for the grainsize and Cu-Au distribution of the porphyry Cu-Au mineralization and associated host rocks.

Drilling techniques

- The Mineral Resource Estimation has been based upon diamond drilling of PQ, HQ and NQ diameters with both standard and triple tube core recovery configurations, RC drilling and surface trenching with channel sampling.

- All drill core drilled by Xanadu has been oriented using the a Reflex orientation tool.

Classification Criteria

- The resource classification was based on drilling density in accordance with the estimation passes (and the availability of data to present to the search neighbourhood, including but not limited to, geological modelling data, oxidation, density and recovery data as well as data quality considerations).

- The classification criteria is deemed appropriate by SGC.

Sample Analysis Methods

- All samples were routinely assayed by ALS Mongolia for gold

- Au is determined using a 25g fire assay fusion, cupelled to obtain a bead, and digested with Aqua Regia, followed by an atomic absorption spectroscopy (AAS) finish, with a lower detection (LDL) of 0.01 ppm.

- All samples were also submitted to ALS Mongolia for the 48-element package ME-ICP61 using a four-acid digest (considered to be an effective total digest for the elements relevant to the Mineral Resource Estimate (MRE)). Where copper is over-range (>1% Cu), it is analysed by a second analytical technique (Cu-OG62), which has a higher upper detection limit (UDL) of 5% copper.

- Quality assurance has been managed by insertion of appropriate Standards (1:30 samples – suitable Ore Research Pty Ltd certified standards), Blanks (1:30 samples), Duplicates (1:30 samples – ¼ core duplicate) by XAM.

- Assay results outside the optimal range for methods were re-analysed by appropriate methods.

- Ore Research Pty Ltd certified copper and gold standards have been implemented as a part of QC procedures, as well as coarse and pulp blanks, and certified matrix matched copper-gold standards.

- QC monitoring is an active and ongoing processes on batch-by-batch basis by which unacceptable results are re-assayed as soon as practicable.

- Prior to 2014: Cu, Ag, Pb, Zn, As and Mo were routinely determined using a three-acid-digestion of a 0.3g sub-sample followed by an AAS finish (AAS21R) at SGS Mongolia. Samples were digested with nitric, hydrochloric and perchloric acids to dryness before leaching with hydrochloric acid to dissolve soluble salts and made to 15ml volume with distilled water. The LDL for copper using this technique was 2ppm. Where copper was over-range (>1% Cu), it was analysed by a second analytical technique (AAS22S), which has a higher upper detection limit (UDL) of 5% copper. Gold analysis method was essentially unchanged.

Estimate Methodology

- Ordinary Kriging technique was employed using third party software based on low coefficient of variation between samples in the mineralised domain.

- Grade interpolation and search ellipses were based on variography and geometry modelling outcomes.

- Modelling was conducted in three passes with block sizes being 20.0 m E by 20.0 m N by 10.0 m RL; discretisation was 5x5x2 for all project areas

- In the first pass data and octant criteria used were, Minimum Data=12, maximum Data=32, Minimum Octants=4. Search radii was 55 mE by 75 mN by 10 mRL.

- An expansion factor of 1 was applied so in the second pass saw the same data and octants criteria with an expanded search to 110mE by 150mN by 20mRL.

- The third pass saw Minimum Data=6, maximum Data=32, Minimum Octants=2. Search radii was 110mE by 150mN by 20mRL.

- Top cutting was applied to domains and elements which displayed a very strongly skewed nature as summarise in the report reference and in accordance with the prevailing coefficients of variation.

- Secondary attributes including the modelling of density which was also modelled on three passes (as above) which included the same data and octant criteria as above.

- No dilution was expressly added to the SGC model however the domain strategy was largely driven by geological and grade domains created by the Client (XM) and provided to SGC which tends to incorporate the full population range in the geological domains and a constrained population range in the grade domains in-line with the grade domain constraints.

- No assumptions were made by SGC regarding the recovery of by-products

- Copper, gold, molybdenum and sulphur were modelled as elements.

- Blocks in the model were defined based on the likely mining bench heights and the domaining took into account the SMU proposed at the outset of 4 m E by 4 m N by 2 m RL.

- The interpretation or domain model was largely driven by the lithology / geology, oxidation state, and structural intervention and mineralised trends observed over the various project areas. Grade was used as a secondary domain driver for the definition of boundaries where deemed appropriate by the XAM resource team.

- The model was validated in a third-party software using section and plan comparisons back to original informing data as well as with the use of swath plots to assess local grade variability between the model and informing data.

Cut-Off Grades & Basis for Selection

- Mineralised domain interpreted on grade >= 0.1% CuEq inside the local interpretation solids by area with reference to local variability and geological consideration.

- Assumed to be reasonable cut-off for open pit and underground propositions given probability plot curve inflexions and grade population distributions.

- Resources estimated at a range of cut-offs and reported at a 0.13% CuEq cut-off grade for open pit, consistent with PFS open pit marginal cut-off grade, and 0.3% CuEq for underground public reporting.

Mining Factors or Assumptions

- This item is beyond the scope of work for SGC as such this item details were not addressed by SGC but will remain the responsibility of the Client and Client’s representatives.

- Consideration was given by SGC to SMU factors, blocks in the model were defined based on the likely mining bench heights and the domaining took into account the SMU proposed at the outset of 4 m E by 4 m N by 2 m RL.

Metallurgical Factors or Assumptions

- No metallurgical factors or assumptions used to restrict or modify the resource estimation were employed by SGC proceeding or during the construction of the model. Metallurgical recovery was not modelled as an attribute of the model. To date metallurgical recovery analysis has indicated recovery of Cu% to be 82% and Aug/t to be 81% overall.6

- The underlying Mineral Resource Estimate is yet to be updated for final met outcomes resulting from recent PFS work, however the cut-off grade is now aligned to the PFS which is based on the most recent metallurgical outcomes. This is issue is not considered material to the estimate.

Other Material Assumptions and Additional Information.

For other material assumptions and additional information, please refer to Appendix 3, JORC Table 1 in this announcement and the following press releases.

- ASX/TSX Announcement 28 August 2024 – Update Increase in Kharmagtai Resource

- ASX/TSX Announcement 14 October 2024 – Kharmagtai Pre-Feasibility Study

- ASX/TSX Announcement 23 December 2023 – Kharmagtai Mineral Resource Grows

- ASX/TSX Announcement 08 December 2021 – Kharmagtai Resource Grows to 1.1 Billion Tonnes

- ASX/TSX Announcement 31 October 2018 – Major Increase in Kharmagtai Open-Cut Resource

- ASX/TSX Announcements 19 March 2015 – Kharmagtai Maiden JORC Resource

For drilling results between 2014 and 2024, please refer to company quarterly reports and press releases, available on the Xanadu Mines website at www.xanadumines.com.

ORE RESERVE OVERVIEW

During the completion of the Kharmagtai PFS (refer separate ASX release for the Kharmagtai PFS), evaluation of an Ore Reserve Estimate was completed. This includes Probable tonnes only. To support the Ore Reserve evaluation within the PFS a separate Whittle 4X open pit optimization evaluation was completed with no value given to the inferred classified material within the mineral resource estimate for all deposits. Following this a PFS level mine design, mine scheduling, mining costing and overall project economic model evaluation was completed to confirm positive economic outcomes for the Ore Reserve.

A summary of material assumptions is provided below and included in JORC Table 1 within this report. There are no material differences between the definitions of Probable Ore Reserves under the 2014 CIM Definition Standards for Mineral Resources and Mineral Reserves and the equivalent definitions in the JORC Code.

Table 6 - Ore Reserve by Classification

| Classification |

Dry Tonnes (Mt) |

Copper Grade (%) |

Gold Grade (g/t) |

Insitu Copper (‘000 t) |

Insitu Gold (‘000 oz) |

| Proved |

0 |

0 |

0 |

0 |

0 |

| Probable |

730 |

0.21 |

0.17 |

1,570 |

4,000 |

Table 7: Ore Reserve by Deposit (all Probable)

Classification

|

Tonnes (Mt)

|

Grades |

Contained Metal |

| Cu (%) |

Au (g/t) |

Cu (kt) |

Au (koz) |

| Stockwork Hill |

233 |

0.22 |

0.21 |

520 |

1,600 |

| White Hill |

437 |

0.21 |

0.14 |

930 |

2,000 |

| Copper Hill |

22 |

0.26 |

0.17 |

60 |

200 |

| Golden Eagle |

13 |

0.12 |

0.31 |

20 |

100 |

| Zephyr |

16 |

0.15 |

0.19 |

20 |

100 |

| White Hill West |

11 |

0.16 |

0.11 |

20 |

40 |

| Probable |

730 |

0.21 |

0.17 |

1,570 |

4,000 |

Notes:

- Figures may not sum due to rounding

- Significant figures do not imply an added level of precision

- Ore Reserve constrained by Kharmagtai PFS mine plan inventory7

- Reserve CuEq equation (CuEq=Cu+Au*0.7039Au) where Au at USD$1900/oz and Cu at USD$4.0/lb was employed according to the Clients' (XAM) direction.

- Au recovery is relative with Cu rec=80% and Au rec=81% according to the Clients' (XAM) direction

Material Assumptions for the Ore Reserve

Kharmagtai is a project at PFS stage based on a conventional open pit, truck and shovel operation feeding a copper concentrator. The Ore Reserve is supported by the PFS Study, and the Project is progressing to the Feasibility Stage. To support the Ore Reserve evaluation within the PFS a separate Whittle 4X open pit optimization evaluation was completed with no value given to the inferred classified material within the mineral resource estimate for all deposits. Following this a PFS level mine design, mine scheduling, mining costing and overall project economic model evaluation was completed to confirm positive economic outcomes for the Ore Reserve. A marginal breakeven cut-off grade of 0.13% CuEq was adopted based on economic parameters and recoveries determined as part of the PFS study. The Ore Reserve statement will be further updated at the completion of the Bankable Feasibility Study.

Ore Reserve Classification

The Probable Ore Reserve is based on Indicated Mineral Resources and diluting material within a regularized resource block model. Diluting material is either low grade Indicated Mineral Resource or material carrying no grade. No Measured Mineral Resource is stated for this deposit. Resource classifications are based on an assessment of geological confidence as a function of geological and mineralisation continuity as outlined in the provided mineral resource estimate.

Risk and Mitigating Actions

Within the Kharmagtai PFS ASX announcement there is detail provided regarding risk and mitigating actions across the following areas:

- Infrastructure and water

- Regulation, permitting and ESG

- Funding

Water

The Project has identified a material risk to the project water supply. The PFS has partially mitigated the risk through exploration and pump testing in a nearby water basin. Water supply will continue to be a core focus of the BFS and will be actioned through a forward work plan in development and prospective areas delineated by the Kharmagtai study team, with important contributions from SRK, senior Mongolian hydrogeologists from Litho Exploration, the Oyut Ulaan government & community relations team, and O2 Mining. The Project has a substantial water resource established nearby which can supply in the range of 50 to 100 l/s of water, but additional make-up water will be required to meet the full Stage 1 demand of 350 l/s. The work during BFS will include a combination of additional exploration in nearby basins and commercial discussions with holders of regional water resources which are not fully utilised. The Stage 2 demand is anticipated to be met through additional borefield exploration, with a strong risk mitigation through the government’s Kherlen Toono project, a major north-south water pipeline. Kherlen Toono is a national industry building program designed to support the mining industry in the Gobi and is currently in Feasibility Study stage. The pipeline will also serve as further risk mitigation for Stage 1.

Mining Operations Summary

The operation is configured as an open pit mine to achieve the highest value, lowest cost, lowest complexity, and most rapid development option. The PFS assumes a contract mining model for mining operations.

Mine Design

The PFS assumes mining will be a conventional drill, blast, load and haul operation. The mine plan is based on 10 metre benches consistent with the current Resource model, and results of an initial Standard Mining Unit assessment. Furthermore, equipment selected is appropriate for the planned selectivity and mining production rates for 10 metre benches. Further optimisation of the Selective Mining Unit (SMU), including bench height will be addressed in the BFS. Grade control will be undertaken from sampling of blasthole cuttings assayed in the on-site laboratory and also planned targeted grade control drilling during operation.

Mine Equipment

The primary mining fleet comprises nominal 600-700t hydraulic excavator (backhoe configuration for mine selectivity and wall control) and 195t large electric rope shovels loading ultra class (nominal 290t capacity) electric drive diesel haul trucks as a well-proven, flexible and efficient match suited to the planned scale of operations. Supplemental primary loading capacity and stockpile reclaim will be provided by 32m3 capacity wheel loaders.

For this PFS and the reserves mine planning, no additional estimate was made for mining dilution and loss due to the gradational nature of the deposit, other than the inherent dilution within the regularized resource model (20m x 20m x10m) used for mining planning. It was also assumed that with this style of mineralisation the geological model incorporates some level of dilution.

Geotechnical Investigation

MineGeoTech was engaged to undertake geotechnical analysis for the project, which included evaluation of geological, structural and alteration environments, material strength, in-situ stress and rock mass quality. The data was used to undertake bench configuration design and overall slope stability analysis using 3D modelling. Slope recommendations were provided to guide pit optimisation by Whittle Consulting Pty Ltd (Whittle) and mine design by the Mining Plus team.

The PFS and reserve mine designs used a conservative bench configuration for the pit slopes and has developed a plan for additional geotechnical study during the BFS. This has potential upside to support steeper interim and final pit slopes.

Pit Optimisation and Operations Configuration

Xanadu engaged Whittle Consulting Pty Ltd (Whittle) to perform the pit optimization study. Whittle used Dassault Systèmes Geovia WhittleTM software to determine the estimated inventories to be mined, and to develop pit phasing strategies. They also used their Prober software to provide strategic guidance to the study configuration. The Resource in each phase was then scheduled on an annualised basis over the LOM using Whittle Consulting’s proprietary Prober-ETM software for a variety of scenarios. The parameters are based on deposits and operations of similar properties providing confidence in the applicability.

Phase selection and analysis of the highest value mining sequence was performed on the deposits both individually and in combination.

The Stockwork Hill and White Hill phases overlapped considerably. The common areas were treated as a set of wedges to be mined as the deposits’ phases required, depending in which phase was scheduled first.

The result was a total of 23 phases incorporating a number of wedges across the 5 deposits. An economic pit could not be defined for the Zaraa deposit based on the assumed costs and metal prices.

Mine Design, Scheduling, Cut-off and Stockpiling

Mining Plus prepared PFS8 level pit designs based on the selected shells (or cutbacks) and used Deswik software to schedule the material in each cutback. The Deswik software was used to focus on material blending and stockpile utilizing the Deswik “Blender” module, with a detailed assessment of primary loading and haulage equipment requirements by year completed using Deswik LHS module to determine annual truck requirements considering detailed haul routes to all destination also including waste rock to be delivered to the two proposed TSF locations.

Deswik determined the multi-mine mining sequence and rate, elevated cutoff to the plant by “bin” varying over time, and stockpiling of lower grade material for processing later, to maximise NPV using the Study assumptions and constraints, and for only indicated resource material for the reserve mine design and schedule.

The mine cut-off grade analysis was calculated based on net sales less smelting, refining deductions, concentrate transport and royalties on a per tonne of ore feed basis regressed against CuEq % over the life of mine to work out a revenue per %Cu per tonne of feed. Unit costs and recovery assumptions were aligned to the PFS. Prices assumed US$4.0/lb Cu and US$1,900/oz Au. The marginal and breakeven costs are then calculated using costs per tonne ore in the financial model against this revenue factor. Marginal breakeven cut-off was determined to be 0.13% CuEq and was utilised for this update to the Open Cut Mineral Resource to align with the PFS, which provided a RPEEE.

The final mining capacity is staged from 100Mtpa to 140Mtpa with a vertical rate of advance limited to 10 benches per year (this constraint was not hit), and a processing capacity staged from 26Mtpa to 52Mtpa.

Sulphide ore is processed through the concentrator, while oxide mineralisation is moved to a designated stockpile for potential future leach processing. A limited amount of gold rich oxide is processed in a CIL circuit.

The first eight years of production (Stage 1) uses predominantly material classified as Indicated (88% of the mine schedule), with other Inferred material stockpiled for processing over the remaining 21-year mine life (Stage 2). Approximately 73% of the 29-year Life of Mine Production Target is in the Indicated Mineral Resource category, and 27% is in the Inferred Mineral Resource category.

The outcome for the selected case is a multi-pit mine schedule mining 1,780M tonnes of waste, processing 1,270M tonnes of ore over 29 years of production to produce 2.1Mt of copper in concentrate and 4.9Moz oz of gold in concentrate and bullion.

Higher-grade ore is prioritised by using a varying elevated cut-off grade to the plant, with by year 9 of production up to approximately 270M tonnes are stockpiled for processing in later years. There is sufficient capacity within the footprints of the ore stockpiles and future waste dumps for this capacity of ore in year 9. The stockpile is depleted from this year until the end of the operations.

WASTE ROCK MANAGEMENT

The Kharmagtai Project comprises extensive systems of open pits, waste rock dumps, LG ore and oxide storage areas, tailings storage facilities, ROM pad, crushing and processing area, and associated roads and infrastructure, as shown in the Kharmagtai PFS Site General Arrangement Figure in this document.

The waste dumps will be constructed such that PAF materials will be encapsulated by NAF material. The as-built waste dumps are designed with a slope of 37 degrees and the final landforms with a shallower slope of 22 degrees to allow for mine closure. Further analysis of the final slope angle is planned as part of further work in the BFS.

An environmental geochemical assessment to support the PFS was conducted based on the available environmental geochemistry data to allow for an initial Acid Rock Drainage (ARD) classification of the waste rock material which was used to inform the design of waste management facilities, waste handling and management.

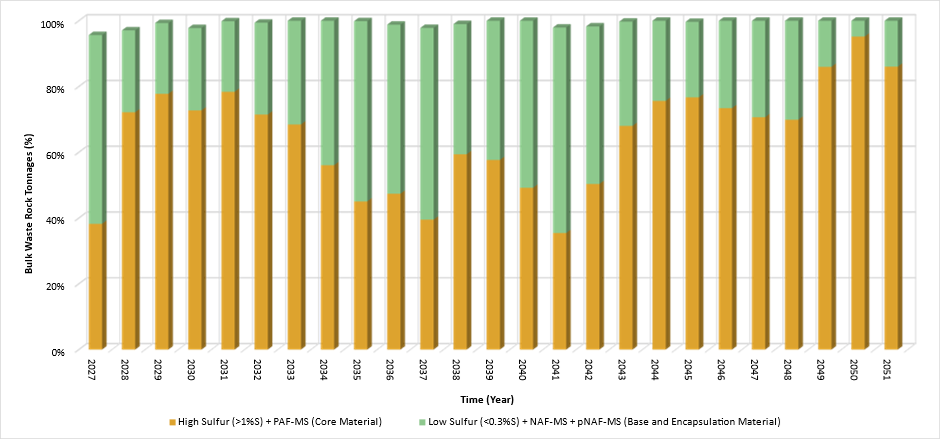

The PFS mine schedule indicated that approximately 63% of the waste rock material is classified as high sulphur waste rock or PAF-MS. Material earmarked for encapsulation (low sulphur, NAF-MS, pNAF_MS) comprises approximately 37% of waste rock as shown in the Figure below. During the PFS checks completed have confirmed, there is overall adequate material to achieve required encapsulation with recommendations for further detailed scheduling of waste rock, and dump design recommended in further studies.

Figure 6 - Classification of Waste Rock Material for Disposal over LOM

Based on the evaluation of the available geochemical data, only a conceptual waste rock management approach can be provided at this stage of the project. A more detailed Mine Waste Management Plan (MWMP) should be developed for the Feasibility Stage (FS), including laboratory testwork to validate and revise material classification.

A conceptual-level closure cost estimate of earthworks associated with the closure and rehabilitation of planned waste rock dumps, stockpiles and infrastructure, was completed as part of the PFS. The estimate is developed as part of an estimate of potential financial obligations following the immediate cessation of mining activities should this occur during planned mining activities.

The high-level analysis encompasses major cost components associated with bulk earth movements for dozing waste dump batters, ripping, developing access roads, capping the tailings facilities, spreading topsoil, and seeding. Mineralised stockpiles including the ROM pad, are assumed to have been processed. The Oxide dump is assumed not to have been processed and will require rehabilitation. The processing plant and all buildings are assumed to have been removed.

At the time of this estimate the future land use, rehabilitation objectives and permitting guidance has not been defined, accordingly the estimate is based on generally practised (Globally) industry standards, to return the mine site to a use similar to its current use prior to mining.

The waste dumps will be profiled to be similar to regional topography based on topographical data, and other information shared by the Xanadu project stakeholders, and also considering observations from the completed site visit by the mining competent person on 15-16 April 2024.

The topsoil and NAF mine waste balance will need to be monitored during operations such that sufficient sources are readily available to implement the coverages in this estimate. Further studies such as a feasibility study should also include more detailed scheduling of both of topsoil and NAF mine waste rock, to ensure movements are adequate and if stockpiling of material may be required.

Mineral Processing

DRA Global completed the PFS process engineering study that demonstrates that a conventional, low risk copper concentrator producing a copper-gold concentrate and gold dore is appropriate for the Project.

A range of options were assessed in concert with the metallurgical test program, based on the option study outcomes, the PFS design for the concentrator was based on two stages, with a Stage 1 throughput rate of 26 Mtpa, fully duplicated in Stage 2 to 52 Mtpa. Modifying factors such as metallurgical overall recoveries for copper of 82% and gold of 81%, and processing costs, etc have been considered and used to support the ore reserve estimate.

Infrastructure, Logistics and Services

Kharmagtai PFS study infrastructure, logistics and services as outlined in the ASX PFS announcement also support the Ore Estimate reserve.

An important consideration is water. The South Gobi region has significant potential water resources which could meet all known demand including Kharmagtai projections. These lie in deep, non-potable industrial aquifers. While a large portion of these resources are not yet claimed, there are also third parties who hold resources but are not utilizing them. The Kharmagtai project has focused on both new and third-party sources.

The PFS project has identified a material risk to the project water supply. The PFS has partially mitigated this risk to its water supply and this will continue to be a core focus of the Bankable Feasibility Study (BFS) with a forward work plan developed. The project has a substantial water resource established nearby, but significant amounts of additional make-up water will be required to be identified to meet the full Stage 1 demand. Kharmagtai requires approximately 350Ml/s make-up water supply for Stage 1, which is roughly doubled for Stage 2.

Make-up water supply costing has been included in the PFS. The make-up water supply risk will de-risked for the operation, and requirements are expected to be met via a detailed technical and commercial work plan during 2025. The commercial plan will engage with other water rights holders who have underutilized resources and will prioritise based on environmental, social, sustainability, technical and financial outcomes. The exploration plan will progress based on a regional survey which has identified high priority targets near the operation. This plan was developed with contributions from SRK, a qualified Mongolian hydrogeologists from Litho exploration, the Kharmagtai government & community relations team, and O2 Mining. The PFS has conservatively costed a commercial supply to provide the additional Stage 1 water.

Furthermore, this plan addresses Stage 2 requirements are anticipated to be met through additional water exploration. Risk mitigation for both Stage 1 and Stage 2 requirements will come from the Mongolian Government’s Kerlen-Toono project (Blue Horse Water Infrastructure Program), which aims to bring a high-capacity water pipeline from the Kherlen River in northern Mongolia to the Gobi within 6-8 years. Kherlen-Toono project is already in Feasibility Study stage, partly funded by Oyu Tolgoi and Tavan Togloi operating mines, and is designed to support the mining industry in the Gobi region. The Kherlen-Toono project was identified within a resolution of the Mongolian Parliament to approve the Cabinet’s 2024-2028 Action Program, which defines 15 specific nation building mega-projects.

Operations Strategy

The operating model selected for the PFS envisages Kharmagtai operating as a long-distance commute site supported by an office in Ulaanbaatar. The project targets Mongolian management with any expatriate roles aimed at training and developing Mongolians into management positions. Details are provided in the Kharmagtai PFS ASX release and supporting study.

Mining operations are structured as a 3rd party contract miner model. Mineral processing, tailings, on-site infrastructure, general and administrative tasks will be owner operated.

Regulatory, Social and Environmental

The work outlined in the Kharmagtai PFS ASX release and supporting study in these areas also support the Ore Reserve Estimate.

About Xanadu Mines Ltd

Xanadu is an ASX and TSX listed Exploration company operating in Mongolia. We give investors exposure to globally significant, large-scale copper-gold discoveries and low-cost inventory growth. Xanadu maintains a portfolio of exploration projects and remains one of the few junior explorers on the ASX or TSX who jointly control a globally significant copper-gold deposit in our flagship Kharmagtai project. Xanadu holds a 50-50 JV share with Zijin Mining Group in Khuiten Metals Pte Ltd, which controls 76.5% of the Kharmagtai project.

For further information, please visit www.xanadumines.com or contact:

| Colin Moorhead |

Spencer Cole |

| Executive Chairman & Managing Director |

Chief Financial & Development Officer |

| P: +61 2 8280 7497 |

P: +61 2 8280 7497 |

| E:colin.moorhead@xanadumines.com |

E:spencer.cole@xanadumines.com |

| W: www.xanadumines.com |

|

|

|

This Announcement was authorised for release by Xanadu’s Board of Directors.

APPENDIX 1: COMPETENT PERSON’S STATEMENT

Mineral Resource Estimate

Mr Robert Spiers is a full time Principle Geologist employed by Spiers Geological Consultants (SGC), 4 Martin Street, Mount Martha, Victoria, Australia. Mr Spiers is contracted on a consulting basis by Xanadu Mines.

Mr Spiers graduated with a Bachelor of Science (BSc) Honours and a double Major of Geology and Geophysics from Latrobe University, Melbourne, Victoria, Australia and has been a member of the Australian Institute of Geoscientists for 26 years; working as a Geologist for in-excess of 30 years since graduating.

Mr Spiers has sufficient experience that is relevant to the style of mineralisation and type of deposit under consideration and to the activity being undertaking to qualify as a Competent Person as defined in the 2012 Edition of the ‘Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves’. Mr Spiers consents to the inclusion in the report to which this statement is to be attached of the matters based on his information in the form and context in which it appears.

The information in the report to which this statement is to be attached that relates to Mineral Resources is based on information compiled by Mr Robert Spiers, a Competent Person who is a Member of the Australian Institute of Geoscientists or a ‘Recognised Professional Organisation’ (RPO) included in a list posted on the ASX website from time to time.

Mr Spiers consents to the disclosure of this information on the page/s in the form and context in which it appears.

To the best Mr Spiers knowledge, neither SGC, himself and / or other related parties have any conflict of interest with by XAM in accordance with the transparency principle set out by the JORC code and supported by ASX rulings.

In relation to the above statement, Mr Spiers holds 750,000 ordinary shares in the ASX listed XAM entity purchased on market in accordance with the XAM trading policy (guidance notes 27). The aforementioned shareholding does not constitute a material holding in the company in question.

Mr Spiers has read the definition of “competent person” set out in the JORC code and guidelines for the reporting of Mineral Resource Estimates and certify that by reason of his education, affiliation with a professional association (MAIG) and past relevant professional work experience, that he fulfils the requirements of a “Competent Person” for the purposes of JORC 2012.

As of the date of this document, to the best of Mr Spiers knowledge, information and belief, the Public Release / Technical Report to which this statement is to be attached (in relation to the Reporting of the Kharmagtai Mineral Resource Estimation October 2024) contains all the scientific and technical information that is required to be disclosed in relation to the Mineral Resources to make the Public Release / Technical Report not misleading with respect to the sections for which Mr Spiers is responsible.

Dated the 14th day of October 2024.

__________________________

Robert Spiers, BSc Hons, MAIG

Our Customer

This report has been produced by or on behalf of Spiers Geological Consultants (SGC) for the sole use by Xanadu Mines (XAM - the Customer). The Customer’s use and disclosure of this report is subject to the terms and conditions under which SGC prepared the report. All items in the report must if used in a third party report be taken in context and consent from SGC must be sought on each occasion.

Notice to Third Parties

SGC prepared this report for the Customer only. If you are not the Customer:

- SGC have prepared this report having regard to the particular needs and interests of the Customer, and in accordance with the Customer’s instructions. It did not draft this report having regard to any other person’s particular needs or interests. Your needs and interests may be distinctly different to the Customer’s needs and interests, and the report may not be sufficient, fit or appropriate for your purposes.

- SGC does not make and expressly disclaims from making any representation or warranty to you – express or implied regarding this report or the conclusions or opinions set out in this report (including without limitation any representation or warranty regarding the standard of care used in preparing this report, or that any forward-looking statements, forecasts, opinions or projections contained in the report will be achieved, will prove to be correct or are based on reasonable assumptions).

- SGC expressly disclaim any liability to you and any duty of care to you.

- SGC does not authorise you to rely on this report. If you choose to use or rely on all or part of this report, then any loss or damage you may suffer in so doing is at your sole and exclusive risk.

Inputs, Subsequent Changes and No Duty to Update

SGC have created this report using data and information provided by or on behalf of the Customer [and Customer’s agents and contractors]. Unless specifically stated otherwise, SGC has not independently verified that data and information unless expressly noted. SGC accepts no liability for the accuracy or completeness of that data and information, even if that data and information has been incorporated into or relied upon in creating this report (or parts of it).

The conclusions and opinions contained in this report apply as at the date of the report. Events (including changes to any of the data and information that SGC used in preparing the report) may have occurred since that date which may impact on those conclusions and opinions and make them unreliable. SGC is under no duty to update the report upon the occurrence of any such event, though it reserves the right to do so.

Mining Unknown Factors

The ability of any person to achieve forward-looking production and economic targets is dependent on numerous factors that are beyond SGC’s control and that SGC cannot anticipate. These factors include, but are not limited to, site-specific mining and geological conditions, management and personnel capabilities, availability of funding to properly operate and capitalize the operation, variations in cost elements and market conditions, developing and operating the mine in an efficient manner, unforeseen changes in legislation and new industry developments. Any of these factors may substantially alter the performance of any mining operation.

Ore Reserve

The information in this Study that relates to Ore Reserves is based on information compiled by Mr Colin McVie and Mr Simon Grimbeek, who are responsible for the Ore Reserve. Both Mr McVie and Mr Grimbeek are full time Managers and Mining Engineers employed by Mining Plus and are both Fellows of the Australasian Institute of Mining and Metallurgy. They both have sufficient experience relevant to the style of mineralisation and type of deposit under consideration and to the activity he is undertaking to qualify as the Qualified Person as defined in the CIM Guidelines and National Instrument 43-101 and as a Competent Person under JORC Code 2012. Mr McVie and Mr Grimbeek consent to the inclusion in the report of the matters based on this information in the form and context in which it appears.

The information in this Study that relates to open pit geotechnical analysis for the project has been reviewed by Dr John Player, BEng (Mining) (Hons) MEngSc (Mining Geomechanics) PhD MAusIMM(CP) RPEQ (Geotech). Dr Player is not an employee of the Company but is Director and Principal Engineer with MineGeoTech. Dr Player is a Member and Chartered Professional of the Australasian Institute of Mining and Metallurgy; has sufficient experience relevant to the style of mineralisation and type of deposit under consideration and to the activity undertaken to qualify as the Qualified Person as defined in the CIM Guidelines and National Instrument 43-101 and as a Competent Person under JORC Code 2012. Dr Player consents to the inclusion in this report of the contained technical information in the form and context as it appears.

The information in this Study that relates to processing, metallurgy and metallurgical testwork has been reviewed by Graham Brock, BSc (Eng), ARSM. Mr Brock is not an employee of the Company but is employed as a contract consultant. Mr Brock is a Fellow of the Australasian Institute of Mining and Metallurgy; he has sufficient experience with the style of processing response and type of deposit under consideration, and to the activities undertaken, to qualify as the Qualified Person as defined in the CIM Guidelines and National Instrument 43-101 and as a Competent Person under JORC Code 2012. Mr Brock consents to the inclusion in this report of the contained technical information in the form and context as it appears.

The information in this Study that relates to marketing and concentrate logistics was reviewed by Albert de Sousa, MAusIMM, BA, Graduate Diploma International Business. Mr de Sousa is not an employee of the Company but is employed as a contract consultant. Mr de Sousa is a member of the Australasian Institute of Mining and Metallurgy. He has sufficient experience the style of mineralisation, type of deposit, and concentrate production and logistics, and to related activities undertaken, to qualify as the Qualified Person as defined in the CIM Guidelines and National Instrument 43-101 and as a Competent Person under JORC Code 2012. Mr de Sousa consents to the inclusion in this report of the contained technical and commercial information in the form and context as it appears.

The technical and scientific information contained in this document related to Kharmagtai PFS was reviewed by Julien Lawrence, MEngSc (PM), FAusIMM, B Eng Mining (Hons). Mr Lawrence is not an employee of the Company but is employed as a contract consultant. Mr Lawrence is a Fellow of the Australasian Institute of Mining and Metallurgy. He has sufficient experience the style of mineralisation and type of deposit, and to the activities undertaken, to qualify as the Qualified Person as defined in the CIM Guidelines and National Instrument 43-101 and as a Competent Person under JORC Code 2012. Mr Lawrence consents to the inclusion in this report of the contained technical information in the form and context as it appears.

Exploration

The information in this announcement that relates to exploration results is based on information compiled by Dr Andrew Stewart, who is responsible for the exploration data, comments on exploration target sizes, QA/QC and geological interpretation and information. Dr Stewart, who is an employee of Xanadu and is a Member of the Australasian Institute of Geoscientists, has sufficient experience relevant to the style of mineralisation and type of deposit under consideration and to the activity he is undertaking to qualify as the Competent Person as defined in the 2012 Edition of the Australasian Code for Reporting Exploration Results, Mineral Resources and Ore Reserves and the National Instrument 43-101. Dr Stewart consents to the inclusion in the report of the matters based on this information in the form and context in which it appears.

APPENDIX 2: ADDITIONAL STATEMENTS AND DISCLAIMERS

Mineral Resources and Ore Reserves Reporting Requirements

The 2012 Edition of the Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves (the JORC Code 2012) sets out minimum standards, recommendations and guidelines for Public Reporting in Australasia of Exploration Results, Mineral Resources and Ore Reserves. The Information contained in this Announcement has been presented in accordance with the JORC Code 2012.

The information in this Announcement relates to the exploration results previously reported in ASX Announcements which are available on the Xanadu website at:

https://www.xanadumines.com/site/investor-centre/asx-announcements

The Company is not aware of any new, material information or data that is not included in those market announcements.

Forward-Looking Statements

Certain statements contained in this Announcement, including information as to the future financial or operating performance of Xanadu and its projects may also include statements which are ‘forward‐looking statements’ that may include, amongst other things, statements regarding targets, estimates and assumptions in respect of mineral reserves and mineral resources and anticipated grades and recovery rates, production and prices, recovery costs and results, capital expenditures and are or may be based on assumptions and estimates related to future technical, economic, market, political, social and other conditions. These ‘forward-looking statements’ are necessarily based upon a number of estimates and assumptions that, while considered reasonable by Xanadu, are inherently subject to significant technical, business, economic, competitive, political and social uncertainties and contingencies and involve known and unknown risks and uncertainties that could cause actual events or results to differ materially from estimated or anticipated events or results reflected in such forward‐looking statements.

Xanadu disclaims any intent or obligation to update publicly or release any revisions to any forward‐looking statements, whether as a result of new information, future events, circumstances or results or otherwise after the date of this Announcement or to reflect the occurrence of unanticipated events, other than required by the Corporations Act 2001 (Cth) and the Listing Rules of the Australian Securities Exchange (ASX) and Toronto Stock Exchange (TSX). The words ‘believe’, ‘expect’, ‘anticipate’, ‘indicate’, ‘contemplate’, ‘target’, ‘plan’, ‘intends’, ‘continue’, ‘budget’, ‘estimate’, ‘may’, ‘will’, ‘schedule’ and similar expressions identify forward‐looking statements.

All ‘forward‐looking statements’ made in this Announcement are qualified by the foregoing cautionary statements. Investors are cautioned that ‘forward‐looking statements’ are not guarantee of future performance and accordingly investors are cautioned not to put undue reliance on ‘forward‐looking statements’ due to the inherent uncertainty therein.

For further information please visit the Xanadu Mines’ Website at www.xanadumines.com.

APPENDIX 3: KHARMAGTAI TABLE 1 (JORC 2012)

Set out below is Section 1 and Section 2 of Table 1 under the JORC Code, 2012 Edition for the Kharmagtai project. Data provided by Xanadu. This Table 1 updates the JORC Table 1 disclosure dated 8 December 2023.

JORC TABLE 1 - SECTION 1 - SAMPLING TECHNIQUES AND DATA

(Criteria in this section apply to all succeeding sections).

| Criteria |

Commentary |

| Sampling techniques |

- Representative ½ core samples were split from PQ, HQ & NQ diameter diamond drill core on site using rock saws, on a routine 2m sample interval that also honours lithological/intrusive contacts.

- The orientation of the cut line is controlled using the core orientation line ensuring uniformity of core splitting wherever the core has been successfully oriented.

- Sample intervals are defined and subsequently checked by geologists, and sample tags are attached (stapled) to the plastic core trays for every sample interval.

- Reverse Circulation (RC) chip samples are ¼ splits from one meter (1m) intervals using a 75%:25% riffle splitter to obtain a 3kg sample

- RC samples are uniform 2m samples formed from the combination of two ¼ split 1m samples.

|

| Drilling techniques |

- The Mineral Resource Estimation has been based upon diamond drilling of PQ, HQ and NQ diameters with both standard and triple tube core recovery configurations, RC drilling and surface trenching with channel sampling.

- All drill core drilled by Xanadu has been oriented using the “Reflex Ace” tool.

|

| Drill sample recovery |

- Diamond drill core recoveries were assessed using the standard industry (best) practice which involves removing the core from core trays; reassembling multiple core runs in a v-rail; measuring core lengths with a tape measure, assessing recovery against core block depth measurements and recording any measured core loss for each core run.

- Diamond core recoveries average 97% through mineralisation.

- Overall, core quality is good, with minimal core loss. Where there is localised faulting and or fracturing core recoveries decrease, however, this is a very small percentage of the mineralised intersections.

- RC recoveries are measured using whole weight of each 1m intercept measured before splitting

- Analysis of recovery results vs grade shows no significant trends that might indicate sampling bias introduced by variable recovery in fault/fracture zones.

|

| Logging |

- All drill core is geologically logged by well-trained geologists using a modified “Anaconda-style” logging system methodology. The Anaconda method of logging and mapping is specifically designed for porphyry Cu-Au mineral systems and is entirely appropriate to support Mineral Resource Estimation, mining and metallurgical studies.

- Logging of lithology, alteration and mineralogy is intrinsically qualitative in nature. However, the logging is subsequently supported by 4 Acid ICP-MS (48 element) geochemistry and SWIR spectral mineralogy (facilitating semi-quantitative/calculated mineralogical, lithological and alteration classification) which is integrated with the logging to improve cross section interpretation and 3D geological model development.

- Drill core is also systematically logged for both geotechnical features and geological structures. Where drill core has been successfully oriented, the orientation of structures and geotechnical features are also routinely measured.

- Both wet and dry core photos are taken after core has been logged and marked-up but before drill core has been cut.

|

| Sub-sampling techniques and sample preparation |

- All drill core samples are ½ core splits from either PQ, HQ or NQ diameter cores. A routine 2m sample interval is used, but this is varied locally to honour lithological/intrusive contacts. The minimum allowed sample length is 30cm.

- Core is appropriately split (onsite) using diamond core saws with the cut line routinely located relative to the core orientation line (where present) to provide consistency of sample split selection.

- The diamond saws are regularly flushed with water to minimize potential contamination.

- A field duplicate ¼ core sample is collected every 30th sample to ensure the “representivity of the in-situ material collected”. The performance of these field duplicates is routinely analysed as part of Xanadu’s sample QC process.

- Routine sample preparation and analyses of DDH samples were carried out by ALS Mongolia LLC (ALS Mongolia), who operates an independent sample preparation and analytical laboratory in Ulaanbaatar.

- All samples were prepared to meet standard quality control procedures as follows: Crushed to 75% passing 2mm, split to 1kg, pulverised to 85% passing 200 mesh (75 microns) and split to 150g sample pulp.

- ALS Mongolia Geochemistry labs quality management system is certified to ISO 9001:2008.

- The sample support (sub-sample mass and comminution) is appropriate for the grainsize and Cu-Au distribution of the porphyry Cu-Au mineralization and associated host rocks.

|

| Quality of assay data and laboratory tests |

- All samples were routinely assayed by ALS Mongolia for gold

- Au is determined using a 25g fire assay fusion, cupelled to obtain a bead, and digested with Aqua Regia, followed by an atomic absorption spectroscopy (AAS) finish, with a lower detection (LDL) of 0.01 ppm.

- All samples were also submitted to ALS Mongolia for the 48-element package ME-ICP61 using a four-acid digest (considered to be an effective total digest for the elements relevant to the Mineral Resource Estimate (MRE)). Where copper is over-range (>1% Cu), it is analysed by a second analytical technique (Cu-OG62), which has a higher upper detection limit (UDL) of 5% copper.

- Quality assurance has been managed by insertion of appropriate Standards (1:30 samples – suitable Ore Research Pty Ltd certified standards), Blanks (1:30 samples), and Duplicates (1:30 samples – ¼ core duplicate) by XAM.

- Assay results outside the optimal range for methods were re-analysed by appropriate methods.

- Ore Research Pty Ltd certified copper and gold standards have been implemented as a part of QC procedures, as well as coarse and pulp blanks, and certified matrix matched copper-gold standards.

- QC monitoring is an active and ongoing processes on batch-by-batch basis by which unacceptable results are re-assayed as soon as practicable.

- Prior to 2014: Cu, Ag, Pb, Zn, As and Mo were routinely determined using a three-acid-digestion of a 0.3g sub-sample followed by an AAS finish (AAS21R) at SGS Mongolia. Samples were digested with nitric, hydrochloric and perchloric acids to dryness before leaching with hydrochloric acid to dissolve soluble salts and made to 15ml volume with distilled water. The LDL for copper using this technique was 2ppm. Where copper was over-range (>1% Cu), it was analysed by a second analytical technique (AAS22S), which has a higher upper detection limit (UDL) of 5% copper. Gold analysis method was essentially unchanged.

|

| Verification of sampling and assaying |

- All assay data QA/QC is checked prior to loading into XAM’s Geobank data base.

- The data is managed by XAM geologists.

- The data base and geological interpretation is managed by XAM.

- Check assays are submitted to an umpire lab (SGS Mongolia) for duplicate analysis.

- No twinned drill holes exist.

- There have been no adjustments to any of the assay data.

|

| Location of data points |

- Diamond drill holes have been surveyed with a differential global positioning system (DGPS) to within 10cm accuracy.

- The grid system used for the project is UTM WGS-84 Zone 48N

- Historically, Eastman Kodak and Flexit electronic multi-shot downhole survey tools have been used at Kharmagtai to collect down-hole azimuth and inclination information for the majority of the diamond drill holes. Single shots were typically taken every 30m to 50m during the drilling process, and a multi-shot survey with readings every 3-5m are conducted at the completion of the drill hole. As these tools rely on the earth’s magnetic field to measure azimuth, there is some localised interference/inaccuracy introduced by the presence of magnetite in some parts of the Kharmagtai mineral system. The extent of this interference cannot be quantified on a reading-by-reading basis.

- More recently (since September 2017), a north-seeking gyro has been employed by the drilling crews on site (rented and operated by the drilling contractor), providing accurate downhole orientation measurements unaffected by magnetic effects. Xanadu have a permanent calibration station setup for the gyro tool, which is routinely calibrated every 2 weeks (calibration records are maintained and were sighted)

- The project Digital Terrain Model (DTM) is based on 1m contours from satellite imagery with an accuracy of ±0.1 m.

|

| Data spacing and distribution |

- The drill-holes spacing ranges from <50m spacing within the core of mineralization to +500m spacing for exploration drilling. The drill-hole spacing can be determined using the sections and drill plans provided.

- Holes range from vertical to an inclination of -60 degrees depending on the attitude of the target and the drilling method.

- The data spacing and distribution is sufficient to establish anomalism and targeting for porphyry Cu-Au, tourmaline breccia and epithermal target types.

- Holes have been drilled to a maximum of 1,400m vertical depth.

- The data spacing and distribution is sufficient to establish geological and grade continuity, and to support the Mineral Resource classification.

|

| Orientation of data in relation to geological structure |

- Drilling is conducted in a predominantly regular grid to allow unbiased interpretation and targeting.

- Scissor drilling, as well as some vertical and oblique drilling, has been used in key mineralised zones to achieve unbiased sampling of interpreted structures and mineralised zones, and in particular to assist in constraining the geometry of the mineralised hydrothermal tourmaline-sulphide breccia domains.

|

| Sample security |

- Samples are delivered from the drill rig to the core shed twice daily and are never left unattended at the rig.

- Samples are dispatched from site in locked boxes transported on XAM company vehicles to ALS lab in Ulaanbaatar.

- Sample shipment receipt is signed off at the Laboratory with additional email confirmation of receipt.

- Samples are then stored at the lab and returned to a locked storage site.

|

| Audits or reviews |

- Internal audits of sampling techniques and data management are undertaken on a regular basis, to ensure industry best practice is employed at all times.

- External reviews and audits have been conducted by the following groups:

- 2012: AMC Consultants Pty Ltd. was engaged to conduct an Independent Technical Report which reviewed drilling and sampling procedures. It was concluded that sampling and data record was to an appropriate standard.

- 2013: Mining Associates Ltd. was engaged to conduct an Independent Technical Report to review drilling, sampling techniques and QAQC. Methods were found to conform to international best practice.

- 2018: CSA Global reviewed the entire drilling, logging, sampling, sample shipping and laboratory processes during the competent persons site visit for the 2018 MRE and found the systems and adherence to protocols to be to an appropriate standard.

- 2024: Ted Coupland reviewed the 2023 Mineral Resource Estimation (MRE) and during this review covered drilling, QAQC, data and documentation. Ted found no issues with the work conducted.

|

JORC TABLE 1 - SECTION 2 - REPORTING OF EXPLORATION RESULTS

(Criteria in this section apply to all succeeding sections).

| Criteria |

Commentary |

Mineral

tenement

and land

tenure

status |

- The Project comprises Mining Licence MV-17387A Kharmagtai, originally granted in September 2013.

- Mining licences are granted for a period of 30 years, extendable twice, for 20 years each time. A mining license holder has the right to conduct mining activities throughout the licence area and to construct structures within the licence area that are related to its mining activities.