Recently, Argentinian lithium producer Orocobre (TSX: ORL) reported lower than expected lithium production in its third fiscal quarter because weather interfered with its evaporation rates of its lithium brines. This reveals two problems with lithium brine production: reliability and geography.

One

analyst pointed out that

Orocobre’s production problems “clearly demonstrate” that production is not a straightforward process. “Weather events are beyond the control of

Orocobre, but this reaffirms that there is still room to improve on the robustness of

operations and reduce production variability from weather impacts,” the analyst stated.

The company reported a 25-per-cent lower evaporation rate compared with the same quarter in 2017 which caused production problems and lithium output to fall 29 percent to 2,802 tonnes of Lithium Carbonate equivalent, from 3,937 tonnes in the December quarter. Its February rates were the lowest since 2011.

Weather has clear impacts on the production at lithium brine operations and with global demand for lithium on the rise, more reliable and consistent methods of production will be required. Lithium brine operations are limited to select climates and regions that can support sufficient weather to ensure economic processing.

The global lithium industry will need $10 billion to $12 billion of investment over the next decade to meet surging demand amid the electric vehicle boom, an executive of Chilean miner SQM said.

Demand for the metal is set to grow by 600,000-800,000 tonnes of lithium carbonate equivalent over the next 10 years, Daniel Jimenez, senior commercial vice president at SQM, said.

Not all lithium is equal and not all lithium is mined the same way. There are two significant sources of lithium, Lithium Brines and Lithium-Cesium Tantalum Pegmatites (hard rock).

Hard rock lithium deposits are going to fill the demand as they are more evenly geographically distributed across the globe and are less dependant on a changing climate for production.

Lithium Brines:

Lithium Brines:

Lithium brine production is currently derived from continental brine deposits. As described by the USGS, lithium brine deposits are accumulations of saline groundwater that are enriched in dissolved lithium. Although abundant in a nature, only select regions in the world contain brines in closed basins in arid regions, where lithium salts can be extracted at a profit.

Figure: Schematic deposit model for lithium brines showing part of a closed-basin system consisting of interconnected subbasins. The subbasin containing the salar is the lowest.

Figure: Schematic deposit model for lithium brines showing part of a closed-basin system consisting of interconnected subbasins. The subbasin containing the salar is the lowest.

Lithium brine evaporation operates as follows. Brine, typically carrying 200 to 1,400 milligrams per liter (mg/l) Li, is pumped to the surface and concentrated by evaporation in a succession of artificial ponds, each one in the chain having a greater Li concentration. After a few months to about a year, depending on climate, a concentrate of 1 to 2 percent Lithius is further processed in a chemical plant to yield various end products, such as lithium carbonate and lithium metal.

The Salar de Atacama is the location of the world’s largest lithium brine mine operated by Sociedad Quimica y Minera de Chile S.A., or SQM (NYSE:

SQM). -

Annual production figures

Geographic distribution of salt brines

Attributes of Lithium Brine:

(1) arid climate;

(2) closed basin containing a playa or salar;

(3) tectonically driven subsidence;

(4) associated igneous or geothermal activity;

(5) suitable lithium source-rocks;

(6) one or more adequate aquifers; and

(7) sufficient time to concentrate a brine, economically

(8) 1 to 2 per cent LiO2 achieved over time and evaporation, then considered economic for processing

Hardrock Mining

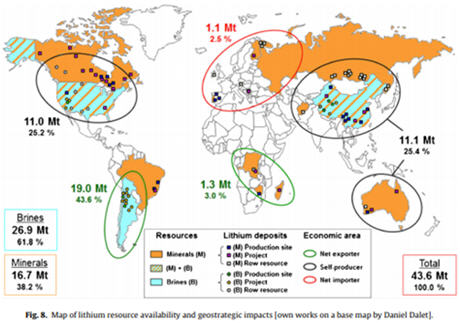

Rock minerals resources are way more homogeneously distributed on Earth with deposits located on each continent. But still, only a few sites are currently producing in Canada, Australia and China.

Lithium found in hard rock forms in crystals that are hosted in Pegmatites which form when mineral-rich magma intrudes into fissures in continental plates. As the last of this magma cools, water and other minerals become concentrated. These metal-enriched fluids catalyze rapid growth of the large crystals that distinguish pegmatites from other rocks. Pegmatites form thick seams called dikes that intrude into barren rock and can measure anywhere from a few to hundreds of meters.

Lithium-cesium-tantalum pegmatites account for about one-fourth of the world’s lithium production, most of the tantalum production, and all of the cesium production. Giant deposits include Tanco in Canada, Greenbushes in Australia, and Bikita in Zimbabwe. The largest lithium pegmatite in the United States, at King’s Mountain, North Carolina, is no longer being mined although large reserves of lithium remain.

According the United State Geological Survey’s 2018 Mineral Commodity Summaries, Australia was the largest producer of lithium. It produced 18,700 MT of lithium last year, up 3,300 MT from the previous year. The 34-percent increase has been attributed to two new spodumene operations that ramped up production to meet strong demand.

Australia hosts the Greenbushes lithium asset, which is operated by Talison Lithium, a subsidiary jointly owned by Tianqi Lithium (SZSE:

002466) and Albemarle (NYSE:

ALB). Greenbushes is the longest continuously operating mining area in Western Australia, having been in operation for over 30 years.

Figure 1. World map showing the locations of LCT pegmatite deposits or districts, including smaller districts in the United States. The symbols are color-coded by age. (source: USGS)

Figure 1. World map showing the locations of LCT pegmatite deposits or districts, including smaller districts in the United States. The symbols are color-coded by age. (source: USGS)

Hard rock lithium mining has few environmental risks that may hold up permitting. With big, stable crystals extracted through conventional means, lithium carbonate pegmatites provide a relatively “dry” and thus safe source of lithium. These pegmatites host a mineral called

spodumene which contains the lithium.

Although miners sometimes encounter

uranium, or beryl and fluorite, both known to be poisonous at high concentrations in drinking water, waste rock from lithium carbonate pegmatite mines differs little from ordinary rock and soil.

Concentrated ores across a narrow surface expression make pegmatite dikes. The high-quality lithium ore is processed into a range of lithium concentrates onsite. These concentrates can be easily packaged and shipped over large distances to market.

Hard rock lithium mining relies on traditional methods of drilling and processing, and presents a more reliable method of mining and opens up deposits closest to major markets within. Hard rock mining is giving countries a competitive advantage over countries dependant on lithium brines for production.

Attributes of Hard Rock lithium:

- Distributed homogeneously throughout the Earth’s crust

- Lithium-cesium-tantalum pegmatites form in orogenic hinterlands as products of plate convergence.

- First-order criteria are an orogenic hinterland setting, appropriate regional metamorphic grades, and the presence of evolved granites and common granitic pegmatites.

- Neither lithium-cesium-tantalum pegmatites nor their parental granites are likely to cause serious environmental concerns

- Traditional mining through movement and crushing of ore

- Economic grades are between 1% and 2% LiO2

So what?

Hard rock lithium has strategic advantages in dynamic lithium markets compared to brine deposits. Extracting lithium concentrate from brine waters involves evaporation in large ponds in unique climates and geography, which may take over a year or more. Hard rock lithium, on the other hand, is easier to explore, mine and process using low-cost mining methods easily that are not ore specific..

Producing lithium from brines is a delicate and weather sensitive process as the majority of evaporation occurs in dry desert regions. The process depends on environmental factors that are beyond a company’s ability to control. Furthermore, it involves tapping into water tables which would require extensive study and could impose disturbances on water uses.

Some scientists propose that the lithium-brine aquifers could be connected in some way with the other water sources. And if they are connected, it is possible freshwater will refill the remote spaces that are emptied by brine pumping, and that would reduce the water resources available for residents.

In August, the Argentinian mining secretary,

fined Sales de Jujuy $1.4 million for changing, without permission, how it was drilling in the salt flat. A portion of the fine was also for spilling sewage on the white salt crust. Orocobre, the company that runs Sales de Jujuy, said it is contesting the fine and denied it broke any rules.

Soils and country rock surrounding a LCT pegmatite, as well as waste from mining operations, may be enriched in characteristic elements relative to global average soil and bedrock values. These elements may include lithium, cesium, tantalum, beryllium, boron, fluorine, phosphorus, manganese, gallium, rubidium, niobium, tin, and hafnium.

Among this suite of elements, however, the only ones that might present a concern for environmental health are beryllium and fluorine, which are included in the U.S. Environmental Protection Agency drinking-water regulations.

According to a 2010 US Geological Survey report, “neither lithium-cesium-tantalum pegmatites nor their parental granites are likely to cause serious environmental concerns.”

Conclusion:

Lithium carbonate production from salt lake brines shows important drawbacks as regards low lithium grades, high dispersions of composition, uncertainty of recovery rate and very long durations necessary either to build new production facilities or to enlarge existing ones. Furthermore, it is subservient to the settling of workers and the transportation of the obtained product in and from isolated desert-like regions.

As far as brines are concerned, those lying in North America come from geothermal and oil fields whereas those located in China are all salt lakes. As a whole, brines resources are very concentrated in places far from the usual centers of consumption, except in some places of United States and Canada.

Lithium extraction from hard-rock minerals is more secure with good lithium grades, high recovery rates, and quick process durations that make it way more suited to any market change. However, the mining damages and thermochemical processes involved are costly and may represent a heavy load for the environment in terms of landscape damage and pollution.

Investor Takeaways:

Lithiums hosted in hard rock are more homogeneously distributed on Earth with deposits located on each continent. But still, only a few sites are currently producing in Canada, Australia and China. This presents a great opportunity for countries to develop their own sources of lithium and for investors of hard rock lithium explorers and developers.

Small-cap hard rock lithium plays

Azincourt Energy Corp. (TSX-V: AAZ)

The company controls 6,368 hectares of pegmatite-rich ground in Manitoba, with historical Li20 numbers & drill-ready targets. Crews are on the ground, beginning prep work for the 2018 work program. Mapping/sampling will get underway, then min 3000m of drilling. Azincourt’s Lithium Two project is adjacent to QMC's Cat Lake Lithium Project

https://azincourtenergy.com/

QMC Quantum Minerals (QMC.V)

The company’s properties include the Irgon Lithium Mine project, a Rare-metal (Li-Ta-Cs) deposit within the Irgon pegmatite located immediately north of Cat Lake Manitoba. The deposit contains an estimated resource of more than 1.2M tonnes of spodumene-bearing pegmatite grading 1.5% Li2O.

https://qmcminerals.com/cat-lake-lithium-project/

Far Resources Ltd (CSE: FAT)

Far Resources, an exploration and development company, will become a leader in the energy metals sector by defining a lithium resource with their Zoro project located in the Snow Lake region of Manitoba. In 1956, the lithium deposit was considered an historic “reserve” based on the drilling of 1.8 million tonnes grading 1.4% Li2O to a depth of 305 m.

https://www.farresources.com/lithium-projects/

MGX Minerals Inc. (CSE: XMG)

MGX Minerals Inc plans to drill the company's Case Lake lithium project in May. Drilling will total 8,000 metres followed by an additional 7,000 metres of planned drilling in the fall. There have been 8,400 metres of drilling completed at Case Lake to date. Substantial spodumene mineralization intersections have included:

- PWM-17-34: 1.81 percent lithium oxide (Li2O) over 17.0 metres;

- PWM-17-33: 2.11 percent Li2O over 11.0 m;

- PWM-17-10: 1.74 percent Li2O over 15.06 m;

- PWM-17-08: 1.94 percent Li2O over 26.0 m.

The Case Lake property is located in Steele and Case townships, 80 kilometres east of Cochrane in Northeastern Ontario close to the Ontario-Quebec border. The Case Lake pegmatite swarm consists of five dikes. MGX currently has a paid-up 20-per-cent working interest in Case Lake and four other lithium hardrock properties in Ontario controlled by Power Metals

https://www.mgxminerals.com

About the author: Nicholas LePan is a seasoned writer covering the metals and mining sector with a keen interest for mineral exploration. You can find his work published in Miningfeeds, Goldseek.com, CEO.ca, and here on

Stockhouse