Researchers from the University of New South Wales have rejected suggestions that end-of-life solar panels will create a “waste mountain” in Australia, saying instead that they could serve as valuable material reservoirs for future production.

DAVID CARROLL Australia is leading the world in its uptake of solar with more than 3.3 million homes having rooftop solar panels, the oldest of which are now beginning to reach their end of life with large volumes of decommissioned panels anticipated within the decade.

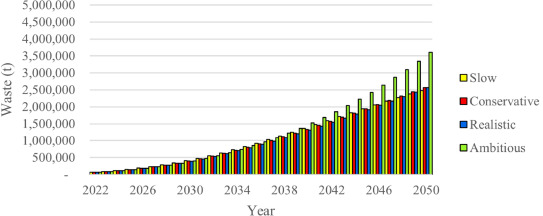

A team of researchers from the University of New South Wales (UNSW) say “conservative” forecasts show that cumulative PV waste in Australia could reach 2 million to 3 million tonnes by 2050. Under ambitious installation projections, waste will be up to twice as much.

The researchers said their forecast is up to seven times higher than previous literature, and one to two times higher than the waste forecast published by the federal government’s Department of Climate Change, Energy, the Environment and Water. More than 80% of the end-of-life panels will initially come from small-scale systems but this share is expected to drop to 60% in 2050.

But rather than looming as a waste mountain, the team from the UNSW’s School of Photovoltaics and Renewable Energy Engineering said end-of-life solar panels are a source of valuable materials such as silver, copper, and high purity silicon, glass, and aluminium which can be utilised in the manufacturing of new modules.

Cumulative waste in tonnes 2022–2050.

Cumulative waste in tonnes 2022–2050. Image: UNSW

Rong Deng, who co-authored the research paper with Renate Egan and Verity Tan, said end-of-life solar has multiple potential market and application opportunities.

“End-of-life PV panels are not waste, they are valuable material reservoirs for the manufacturing of new panels,” she said.

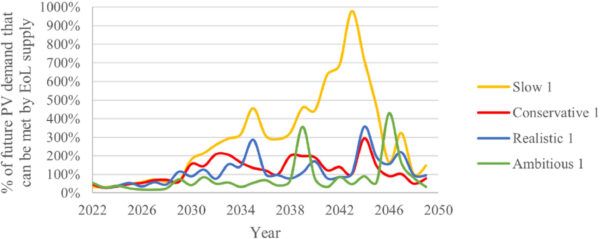

“In five years, end-of-life silver and aluminium from PV panels could supply 30% of future PV demand, 50% in 15 years, escalating to 100% in 25 years considering realistic forecast installations.”

“Imagining meeting all future demands by reusing and recycling, not mining – a truly inspiring prospect.”

In their paper, Solar photovoltaic waste and resource potential projections in Australia, 2022–2050, the researchers have gone beyond forecasting the scope of the waste stream to estimate the resource potential of waste PV material to assist in the manufacturing of new modules.

Assessment of the percentage of silicon PV demand that can be met by end-of-life silicon supply, 2022–2050.

Assessment of the percentage of silicon PV demand that can be met by end-of-life silicon supply, 2022–2050. Image: UNSW

The team said exploring the reuse potential of secondary materials in the manufacturing of new modules will have significant benefits on material supply security within the industry.

“Understanding waste streams can assist in predicting the availability of these recycled resources and to what extent they can contribute to manufacturing of the required cumulative demand,” they said. “This will be increasingly important as the demand for manufacturing of new modules grows, thereby placing stress on critical resource reserves.”

The paper shows that, when all scenarios and lifetime variations are considered, end-of-life panels could in just five years supply more than 30% of aluminium and silver PV demand.

“Moving 10 years ahead, as the amount of waste surpasses 1 million tonnes, in 2038 there will still be ample demand for PV circularity if we install ambitiously or realistically,” the researchers said. “Specifically, an average of around 50% of future PV silver and aluminium demand could be supplied by end-of-life PV.”

By 2045, this supply potential of silver and aluminium begins to stabilise at approximately 100%, allowing up to 100 % circularity within the PV industry for these materials.

“This means there will be clear demand within the PV industry for end-of-life supply if panels are properly recycled,” the researchers said, noting that in practice the end-of-life PV material will likely have multiple potential market and application opportunities, including the battery, ceramic tiles, cosmetic and paint making, construction and bricks industries.

While pointing out the potential benefits that end-of-life solar will offer for material supply security within the industry, the researchers said the planning for PV end-of-life management needs to begin now, with little more than 10 years to prepare for 1 million tonnes of PV waste.

“We know the locations where PV waste will first arise allowing the planning of logistics, we know the PV waste will primarily comprise of silicon-based technologies, so we can investigate appropriate recycling methods, and we know that the majority of PV waste will come from residential and small-commercial users, enabling the development of consumer-appropriate policy,” they said.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.