Renewable energy sources have expanded significantly in recent years, especially wind and solar. One of the largest issues with wind and solar energy sources is the need to store and release the electrical energy produced. A promising storage technology is vanadium redox flow batteries that will increase the demand for vanadium.

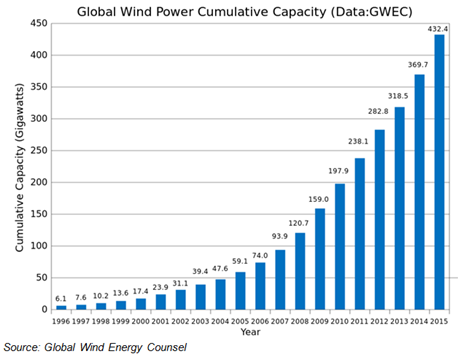

An example of the significantly expanded renewable energy sources is wind energy. Global wind energy production has increased eightfold in the last 10 years.

After setting new records in 2014, the wind power industry experienced another record-breaking year in 2015, with 22% annual market growth and passing the 60 GW mark for the first time in a single year. According to the Global Wind Energy Counsel (“GWEC”), capacity growth will continue at double-digit growth rates and almost double the 2015 capacity by 2020.

After setting new records in 2014, the wind power industry experienced another record-breaking year in 2015, with 22% annual market growth and passing the 60 GW mark for the first time in a single year. According to the Global Wind Energy Counsel (“GWEC”), capacity growth will continue at double-digit growth rates and almost double the 2015 capacity by 2020.

Three big trends in my view will continue to drive growth in the medium term:

Climate Change:

The long-term targets adopted by the 186 countries gathered at the UN Climate Change Conference held in Paris in 2015, is a

de facto call for a 100% emissions-free power sector by the year 2050 -- benefiting renewable energy development such as wind and solar.

Falling Prices:

The costs of both wind and solar technology have fallen dramatically in recent years, and innovative financing and government subsidies are creating conditions for renewable energy sources to be competitive in many countries.

US Market Stability:

President Obama signed into law a long-term extension and phase-out of the Production Tax Credit (PTC) which has been the main federal policy mechanism of support for wind energy in the US. So, the US wind industry now embarks on its longest-ever period of policy stability, and the potential implications of this go far beyond the US market. The incoming US Secretary of Energy, Rick Perry, is a strong proponent of wind energy.

In their document,

BP Energy Outlook 2035, the British multinational company, BP p.l.c. sees Europe leading the charge, with renewable energy accounting for 32% of its electricity generation by 2035.

All the while, BP sees China showing the largest absolute increase in renewables, as it looks to any source other than coal:

The high growth of renewable energy both in absolute numbers and as a share of total power supply, invites the questions:

How to plug the hole in the grid supply when the wind stops and the sun does not shine?

What to do with excess wind and solar power?

Batteries are the most practical solution.

The emergence of utility-scale battery storage for energy is happening now, accelerating, and will get bigger in the next two to five years, according to Andrew Slaughter, the Center’s Executive Director and co-author of

Electricity Storage Technologies, Impacts, and Prospects[1].

Lithium-ion batteries have taken the lion’s share of the energy storage market, but technological

advances in flow batteries that bring down costs and improve their safety and environmental profile are likely to boost utility-scale installations and deployments. Compared to lithium-ion batteries, vanadium redox flow batteries (VRB) are non-flammable, environmentally friendly, have estimated lifespans in excess of 10,000 cycles and maintain 90% of their capacity over 20 years thereby lowering the total cost of ownership. Getting 1,000 cycles of use out of a lithium-ion battery with full depth of discharge however, would be ambitious.

VRB is ideal for “grid constrained” solar and wind farms that currently struggle to sell their electricity at times of peak production but find other forms of storage are not economical. The other advantage of VRB over lithium-ion batteries are a longer continuous discharge run time (6-10 hours versus 2-5 hours). The downside for VRB is their relatively lower round-trip efficiency (measured by power out over power in) of 70% compared to 85% with lithium batteries.

“…in Japan, Hokkaido Electric Power Co.’s 15-megawatt/60-megawatt-hour vanadium redox flow battery from Sumitomo [Electric Industries, Ltd.] started operation last December. Located next to one of the country’s largest solar power plants, it will be used for frequency regulation as well…. Korea’s largest battery installation was Korea Electric Power Corp.'s 28-megawatt lithium-ion array, which has also been earmarked for frequency regulation and will serve the grid around Seoul. The country says it is planning up to

2 gigawatts of storage by 2020.

‘Stationary energy storage continues to show strong growth in the number of projects delivered, the total amount of energy storage deployed, and the size of utility-scale storage systems. These trends are likely to continue as storage increasingly becomes a grid management asset, and we will consistently see records broken for the capacity of the largest stationary energy storage plants,’ said Dean Frankel, an analyst from Lux [Research]’s energy storage team.”

[2]

It’s clear current utility-scale battery storage deployment is in its early infancy. However battery storage technology appears to be inching closer to a “sweet spot” due to the increase in storage demand from renewable energy and rapid advances in technology that drives down cost.

According to article titled “How Soon Can Tesla Get Battery Cell Costs Below $100 per Kilowatt-Hour?” at Greentechmedia dated March 15, 2016

https://www.greentechmedia.com/articles/read/How-Soon-Can-Tesla-Get-Battery-Cell-Cost-Below-100-per-Kilowatt-Hour

"“Ben Kallo at equity analyst firm, Baird, believes that Tesla's current battery costs are ~$150 to ~$200 per kilowatt-hour – well below the industry average pack costs of ~$350 per kilowatt-hour (as

estimated by Bloomberg New Energy Finance). Kallo suggests that Tesla "could reach its <$100 per kilowatt-hour target in the intermediate term as Gigafactory production ramps up”.

The VRB cost is slightly behind the curve at $300/kWh to $500/kWh, however those costs are half of what they were 3 years ago and set to come down further. VRB can be stacked up to increase storage capacities whereas lithium-ion storage capacities are somewhat boxed-in by initial design. Unit cost for large-scale VRB goes down whereas it goes up for lithium-ion batteries. This means on a large-scale deployment, VRB is already likely competitive with lithium-ion batteries today.

The article: “How Cheap Can Energy Storage Get? Pretty Darn Cheap” provides a great overview on the cost versus benefit of energy storage:

“The cost of energy storage is, roughly, the up-front capital cost of the storage device, divided by the number of cycles it can be used for. If a battery costs $100 per kwh and can be used 1,000 times before it has degraded unacceptably, then the cost is one tenth of a dollar (10 cents) per cycle.”

[3] The article states earlier: “If you’re informed on wholesale electricity prices, the prices above may sound ridiculously high. Wholesale natural gas electricity from a new plant is roughly 7 cents per kwh (though that doesn’t include the cost of carbon emitted). How could batteries priced at 25 cents per kwh, or even 10 cents a kwh, compete? Particularly when you also have to pay for electricity to go into those batteries?

The answer is that

batteries don’t compete with baseload power generation alone. Batteries deployed by utilities allow them to reduce the use of (or entirely remove) expensive peaker plants that only run for a few hours a month. They allow utilities to reduce spending on new transmission and distribution lines that are (up until now) built out for peak load and which sit idle at many other hours. In a world with batteries distributed close to the edge, utilities can keep their transmission lines full even during low-demand hours, using them to charge batteries close to their customers, and thus cutting the need for transmission and distribution during peak demand. And batteries reduce outages.”

[4]

Significant research is underway by about a dozen active players in the VRB manufacturing sector. Starting with version one of VRB which was developed and deployed by Japan’s Sumitomo and Germany’s GILDEMEISTER energy solutions, the US Department of Energy’s Pacific Northwest National Laboratory (PNNL) has in recent years developed

a new vanadium electrolyte, one with the promise to increase energy storage capacity by 70 percent from previous versions. The new electrolyte can also increase the operating temperatures of the batteries they’re used in, giving them more power delivery punch, as well as a potentially longer lifespan.

“‘So far, three companies have licensed this PNNL technology', according to [Russ Weed, Vice-President of Business Development and General Counsel for Mukilteo, Washington-based

UniEnergy Technologies]. The first is

Imergy, the Fremont, Calif.-based startup formerly known as Deeya, which

switched from iron-chrome to vanadium flow battery technology last year. The second is

WattJoule, a Massachusetts-based startup.”

[5]

UniEnergy was founded in 2012 and has raised more than $50 million from investors including

a fresh $25 million funding round in 2016 from investors including Orix Corporation, a Japanese financial services firm with business lines in renewable energy project development and energy storage and seed round from

Dalian Bolong Holding Co., Ltd., of China, which also happens to own one of the largest suppliers of vanadium and the maker of a central part of the battery hardware.

Imergy Power Systems raised more than $100 million in 2014 from Technology Partners, New Enterprise Associates (NEA), DFJ, BlueRun Ventures and SunEdison to commercialize a long-duration energy storage solution. The company pivoted from its original iron-chromium chemistry to a vanadium electrolyte in 2013.

Boston-based

Vionx Energy recently raised about $58 million in 2015 from VantagePoint and Starwood Energy. Vionx just announced an "ecosystem" of firms to launch and commercialize its flow batteries. The Vionx vanadium flow storage system was developed by researchers at United Technologies Corporation. Siemens will serve as the EPC for future projects.

It’s clear smart money is pouring some serious cash into the VRB sector in just the past two years.

Turning to the key ingredient of VRB: “vanadium is a soft, silvery gray mineral that's classified as a ductile transition metal. In its various market applications, vanadium represents a billion-dollar industry…. [where] demand is projected to more than double by 2025’

[6] thanks to new vanadium market applications and the expansion of conventional applications.

Vanadium is produced as a by-product of steel smelter slag, and is also mined in two different types of mineral deposits: disseminated in carbon rich deposits and shales, and in magnetite (iron oxide) deposits alongside titanium.

The three largest vanadium producers are China, South Africa and Russia. In North America, vanadium production comes from spent catalyst, residues from burning coal and heavy oil, byproduct of uranium mining, and imported pig iron slag….

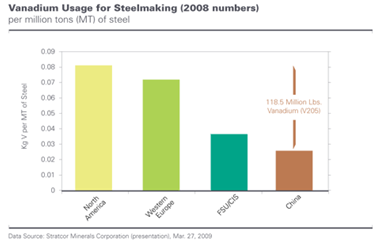

Conventional and new vanadium applications include… steelmaking, grid scale renewable energy storage, high performance batteries, catalysts and chemicals.

…steelmaking accounts for roughly 92% of all vanadium currently consumed, it's estimated that vanadium is only used in about 9% of all steels today.

[7]

When a very small amount of vanadium is added to steel, high-strength low-alloy vanadium steel is created while greatly reducing energy, shipping and production costs.”

[8]

That 9% is expected to grow as emerging economies incorporate vanadium steel into infrastructure development.

[1] A. Slaughter, “Electricity Storage Technologies, Impacts, and Prospects” (September 2015) Deloitte Center for Energy Solutions.

[6] T. Perles, “Vanadium Market Fundamentals and Implications” (November 16, 2010) TTP Squared, Inc.

[8] “Vanadium Outlook” American Vanadium, www.americanvanadium.com/vanadium-outlook.php#footnotes

After steelmaking, the second largest market for vanadium is that of catalysts and chemical applications. While currently representing up to 5% of global consumption, demand is expected to grow in connection with the reduction of emissions from coal-fired power plants in developing economies such as China and India, as well as emissions from vehicles via catalytic converters.

By combining VFBs with renewable energies such as wind and solar, inherently intermittent energy supplies can be regulated from moment to moment, allowing the grid to balance the amount of energy being put into the wires with the demand arising from consumers. Thus VFBs make for a new and potentially increasing demand for vanadium.

Vanadium metal price charts are not readily available to the public online, so I have provided ferro-vanadium price trend information as it is a good proxy to the vanadium metal price.

Vanadium accounts for 30% to 50% of the cost of VRB, making it essential for VRB manufacturers to secure vanadium supply. Billions of dollars have poured into VRB research and development in the past decade, with inevitable mass utility-scale VRB adoption, thus the long-term vanadium price trend looks promising, making for increased interest in miners that produce vanadium metal. One need only look at lithium exploration companies as an example:

There are currently no operating primary vanadium mines in North America and only a handful of vanadium deposits in North America. Prophecy Development Corp. (TSE: PCY) is looking to develop its 80% owned Titanium-Vanadium-Iron deposit, “Titan” into production. Titan is an exploration stage project situated in Ontario, Canada with good infrastructure. Mine Development Associates prepared the Titan technical report dated February 26, 2010, which is compliant with National Instrument 43-101, that discloses a resource estimate prepared according to the CIM Definition Standards for Mineral Resources and Reserves, and was filed on SEDAR by Prophecy. The resource estimate by Mine Development Associates states Titan has 49 million tonnes of inferred resource, grading 0.24% vanadium (Company estimated 0.43% vanadium pentoxide). Based on this resource and grade, Prophecy estimates Titan contains 259 million pounds of vanadium metal assuming 100% recovery. The report is available at:

https://www.prophecydev.com/pdf/titan_feb2010.pdf.

I manage Prophecy Development Corp. (TSX: PCY) which engages in vanadium exploration.

John Lee, CFA.

jlee@prophecydev.com

John Lee, CFA

John Lee, CFA is an accredited investor with over two decades of investing experience in metals and mining equities. Mr. Lee joined the parent company of Prophecy Development Corp. (www.prophecydev.com) in 2009 as the Company’s CEO. Under John Lee’s leadership, Prophecy raised over CAD100 million through the Toronto Stock Exchange and acquired a portfolio of assets including a silver-zinc-lead asset in Bolivia, coal assets in

Mongolia, and a titanium-vanadium-iron project in Canada. John Lee is a Rice University graduate with degrees in economics and engineering.

The technical content of this article was reviewed and approved by Christopher M. Kravits CPG, LPG, who is a Qualified Person within the meaning of National Instrument 43-101. Mr. Kravits is a consultant to the Company and serves as its Qualified Person and General Mining Manager.