New division will have a complete portfolio of products and services to significantly reduce GHG emissions, and convert toxic landfill waste streams into valuable products, for the aluminum industry

MONTREAL, Oct. 20, 2021 (GLOBE NEWSWIRE) -- PyroGenesis Canada Inc. (http://pyrogenesis.com) (TSX: PYR) (NASDAQ: PYR) (FRA: 8PY), a high-tech company (hereinafter referred to as the “Company” or “PyroGenesis”), that designs, develops, manufactures and commercializes advanced plasma processes and sustainable solutions which are geared to reduce greenhouse gases (GHG), is pleased to announce today that, further to its press release dated September 27th, 2021, it has created a new division, PyroGenesis Aluminum (PyroGenesis-Al) dedicated exclusively to PyroGenesis’ environmental offerings to the aluminum industry.

PyroGenesis’ Aluminum portfolio will include five main offerings: (i) Drosrite™ sales and tolling services; (ii) valorization of downstream dross residues; (iii) upstream applications; (iv) PyroGenesis’ high powered plasma torches geared to replacing fossil fuel burners and (v) repurposing of spent pot lining residues recovery. The combination of these offerings is designed to position PyroGenesis Aluminum as a unique one-stop shop for zero landfill / reduced carbon service solutions, which cater to the Aluminum industry.

“Following our successful Joint Venture agreement, with a leading residue processor to transform aluminum dross residues into high value chemical products, and the recent success of our yet-to-be-announced upstream applications, we decided to form a division specifically dedicated to the aluminum industry,” said Mr. P. Peter Pascali, CEO and Chair of PyroGenesis. “PyroGenesis-Al is positioned to offer a complete portfolio of products and services that drive GHG emissions reduction, as well as repurpose toxic land-fill waste streams into valuable products, for the aluminum industry. As such, we believe that PyroGenesis-Al is well positioned to address many of the key environmental challenges facing the industry.”

“Due to their strong, durable, and lightweight characteristics, aluminum products are frequently marketed as a green material,” said Mr. David D’Aoust, Sales Manager Drosrite™ of PyroGenesis. “These qualities have led aluminum to become a key material in the decarbonization of the transportation industry for example, through enabling electrification (electric vehicles). Furthermore, aluminum is infinitely recyclable, making it an excellent candidate for replacing plastics in consumer-packaged goods. However, two key drawbacks are that (i) current production processes result in significant amounts of GHG emissions as well as (ii) the need to landfill hazardous wastes. We believe that these drawbacks can be addressed by our unique offerings and, as such, PyroGenesis can make significant contributions and truly make aluminum the real green material of the future.”

PyroGenesis-Al Offerings:

Drosrite™

PyroGenesis’ Drosrite™ offers the aluminum industry an economically and environmentally sound solution to processing their dross (a waste stream containing valuable metal), eliminating landfill, while at the same time contributing to reducing GHG emissions:

- Direct: due to savings in transportation and avoiding burning fossil fuels in a Rotary Salt Furnace (RSF)

- Indirect: due to the increased recovery of aluminum (less emissions than producing aluminum from primary resources)

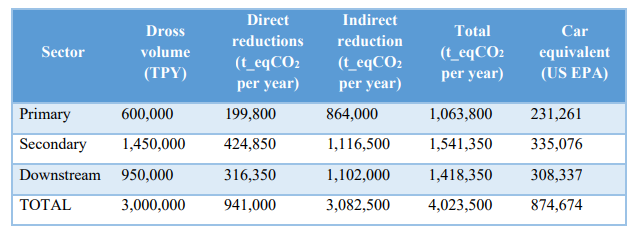

The following table1, based on internal calculations, summarizes the potential emissions reduction assuming all the dross produced in the world2 was treated with Drosrite™.

Based on this analysis, more than 4 million tonnes of GHG can be reduced each year (which is the equivalent of removing close to 875,000 cars from the road each year) if the world’s aluminum dross was treated with Drosrite™. According to the US EPA, an average passenger car in the US emits 4.6 tons of CO2 per year3. This equates to removing an average of 1,458 cars per year, for each of PyroGenesis’ 5 tonnes systems, or close to 3,000 cars per year for each of the Company’s 10 tonnes systems.

Valorization of downstream dross residues

Aluminum dross is typically comprised of two elements: (i) aluminum metal (60%), and (ii) aluminum oxides (40%). PyroGenesis’ Drosrite™ system can recover up to 98% of the aluminum metal fraction. It is this remaining 40% aluminum oxide (dross residues) material that is often landfilled or sold as a cheap additive. Following the Joint Venture’s (JV) announcement, it is expected that these residues could now be processed by the JV, and converted into high margin products, such as aluminum sulfate and ammonium sulfate, thereby transforming a waste stream into a valuable product and unlocking a potentially significant new revenue stream for the Company.

PyroGenesis’ Proprietary Plasma Torches

Many of the largest primary aluminum smelters already own, and generate, their own electricity to reduce costs, since electricity costs are among one of the most significant operating expenses in production. For example, Quebec’s rapidly growing aluminum industry is enhanced by affordable and renewable hydro electricity generation. Among the largest GHG emission sources are the fossil fuel burners used across the smelters’ operations to heat kilns and furnaces. Given the immense and affordable electrical infrastructure already existing at aluminum smelters, PyroGenesis’ plasma torches represent an opportunity for simple electric powered bolt-in replacements to fossil fuel burners. PyroGenesis’ torches are designed to significantly reduce GHG emissions.

Repurposing Spent Pot Lining

As previously announced, the Company is currently developing a new technology to address a significant problem facing the aluminum industry; what to do with residues generated from spent pot liners (“SPL”). PyroGenesis is currently developing a new SPL technology, in partnership with a major Quebec aluminum smelter, Aluminerie Alouette, based on its core plasma waste destruction technologies that are currently in use with the US Navy. This process is designed to transform SPL residues into a fuel that is lower in carbon, as well as into materials that are inert and reusable. In turn, this process provides an alternative to landfill disposal of SPL residues and potentially other industrial by-products, while significantly reducing specific GHG emissions. This process is a closed loop solution at the smelter’s site, eliminating the current industry reliance upon the cement industry for disposal of hazardous waste fractions.

“These offerings are quite timely given the environmental pressure facing the industry, and we expect to continue to build upon recent successes,” said Mr. Pascali. “On the back of introducing our Drosrite™ offering, our technology won one of the largest dross processing tenders put out to bid. This was a significant achievement and was the impetus for the announcement today. In addition to this, we expect to sign our first tolling agreement in Europe by year end. This would cap our sales/tolling strategy for Drosrite (™).”

Mr. Pascali added that: “Once inside the fence, we rapidly identified both downstream and upstream opportunities. With respect to downstream opportunities, we recently signed a JV agreement which will enable us to process residues, typically destined for landfill/cheap aggregate into high value chemical products. We have already identified the first opportunity and we should have more news on this in the coming months. As exciting as our downstream opportunities, we provided an update on our upstream opportunity in the Outlook section of our financial statements dated August 16th, where we noted that the $40MM opportunity was delayed. We also identified a second opportunity, where again, we seem to be the preferred contender. Despite the delay, which is beyond our control, we are excited by the fact that in both instances, we are the lead contenders and as such, has confirmed that we have identified a very compelling offering. Last but not least, the work we are doing to develop environmental solutions (such as repurposing spent pot lining residues), to discerning players in the industry demonstrates the success we are having in becoming a go-to environmental solutions company to a very conservative industry.”

About PyroGenesis Canada Inc.

PyroGenesis Canada Inc., a high-tech company, is a leader in the design, development, manufacture and commercialization of advanced plasma processes and sustainable solutions which reduce greenhouse gases (GHG), and are economically attractive alternatives to conventional “dirty” processes. PyroGenesis has created proprietary, patented and advanced plasma technologies that are being vetted and adopted by multiple multibillion dollar industry leaders in four massive markets: iron ore pelletization, aluminum, waste management, and additive manufacturing. With a team of experienced engineers, scientists and technicians working out of its Montreal office, and its 3,800 m2 and 2,940 m2 manufacturing facilities, PyroGenesis maintains its competitive advantage by remaining at the forefront of technology development and commercialization. The operations are ISO 9001:2015 and AS9100D certified, having been ISO certified since 1997. For more information, please visit: www.pyrogenesis.com.

This press release contains certain forward-looking statements, including, without limitation, statements containing the words "may", "plan", "will", "estimate", "continue", "anticipate", "intend", "expect", "in the process" and other similar expressions which constitute "forward- looking information" within the meaning of applicable securities laws. Forward-looking statements reflect the Corporation's current expectation and assumptions and are subject to a number of risks and uncertainties that could cause actual results to differ materially from those anticipated. These forward-looking statements involve risks and uncertainties including, but not limited to, our expectations regarding the acceptance of our products by the market, our strategy to develop new products and enhance the capabilities of existing products, our strategy with respect to research and development, the impact of competitive products and pricing, new product development, and uncertainties related to the regulatory approval process. Such statements reflect the current views of the Corporation with respect to future events and are subject to certain risks and uncertainties and other risks detailed from time-to-time in the Corporation's ongoing filings with the securities regulatory authorities, which filings can be found at www.sedar.com, or at www.sec.gov. Actual results, events, and performance may differ materially. Readers are cautioned not to place undue reliance on these forward-looking statements. The Corporation undertakes no obligation to publicly update or revise any forward- looking statements either as a result of new information, future events or otherwise, except as required by applicable securities laws. Neither the Toronto Stock Exchange, its Regulation Services Provider (as that term is defined in the policies of the Toronto Stock Exchange) nor the NASDAQ Stock Market, LLC accepts responsibility for the adequacy or accuracy of this press release.

SOURCE PyroGenesis Canada Inc.

For further information please contact:

Rodayna Kafal, Vice President, IR/Comms. and Strategic BD

Phone: (514) 937-0002, E-mail: ir@pyrogenesis.com

RELATED LINK: http://www.pyrogenesis.com/

1 Based on internal calculations

2 Aluminum Dross Processing; A Global Review, AlCircle.com

3https://www.epa.gov/greenvehicles/greenhouse-gas-emissions-typical-passenger-vehicle#:~:text=typical%20passenger%20vehicle%3F-,A%20typical%20passenger%20vehicle%20emits%20about%204.6%20metric%20tons%20of,8%2C887%20grams%20of%20CO2